Occupational safety

Basic approach

The Idemitsu Group's safety philosophy is to "make people's safety our number one priority, reduce and eliminate risks through appropriate allocation of management Resources, maintenance and improvement of facilities, processes and work systems, and strive to eliminate accidents and disasters while cultivating a culture of safety." Safety based on this philosophy is the result of management efforts, and zero accidents and disasters is the greatest achievement in this field. Based on this recognition, we have made safety the most important and prioritized standard in various value judgment criteria for all business activities, such as production, logistics, sales, and research and development, all work, and all actions in each situation and stage. We have established the following specific policies in our internal regulations, "Basic Principles for Safety, Health and the Environment," and are working to ensure the health, safety and security of all people related to our company.

Policy

Ensuring safety

1. Ensure the safety of people

2. Ensure the safety assurance of facilities and processes

3. Ensure safety in the work mechanisms and procedures

4. Properly allocate and utilize management resources

5. Cultivate safety culture and promote safety management

Furthermore, to ensure the implementation of the "Basic Policy for Ensuring Safety," we have formulated the "Occupational Safety and Health Management Regulations," based on which we have established a system for ensuring safety and occupational health, as well as procedures for formulating, implementing, evaluating, and continuously improving plans (occupational safety and health management system). We strive to ensure the safety of all workers, including employees and employees of affiliated companies, and to maintain and improve safety standards.

Governance

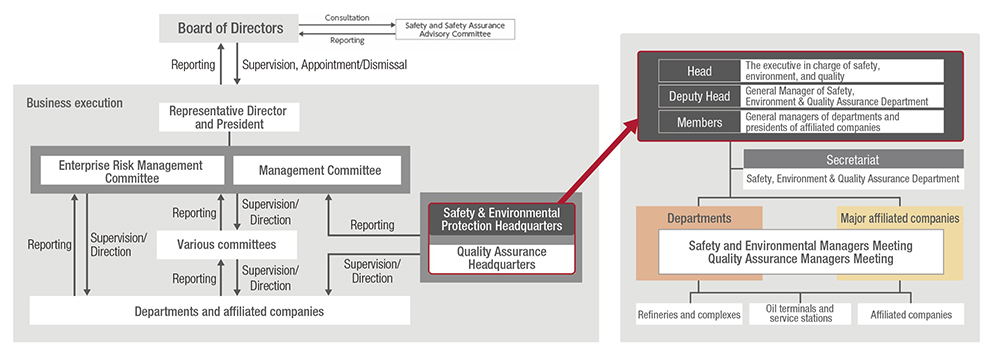

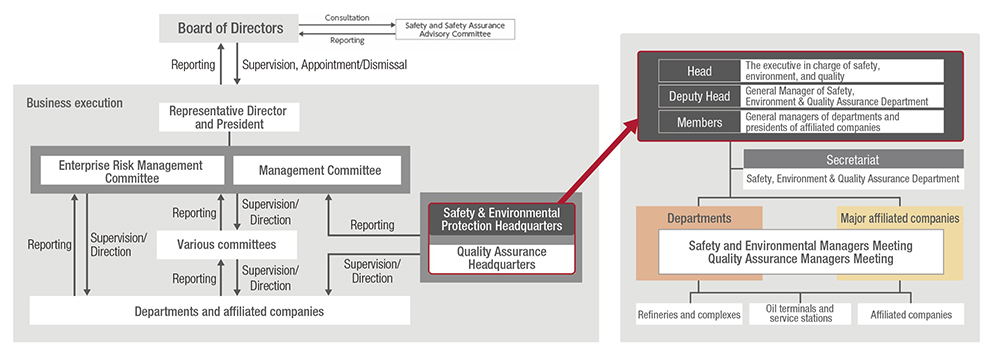

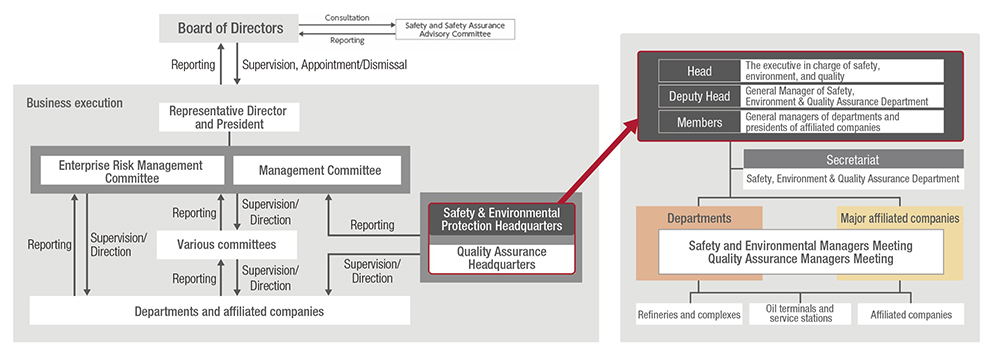

Promotion system for safety, health and environment initiatives

The Group has long positioned "safety, health, and the environment" as the foundation of its management, and has established "Safety & Environmental Protection Headquarters" to promote efforts to secure and preserve these areas. The Safety & Environmental Protection Headquarters consists of the Safety & Environmental Protection Headquarters President, the Deputy General Manager, the President of the General Managers and major affiliates concerned, and other persons appointed by the Safety & Environmental Protection Headquarters Heads and the Secretariat.

The officer in charge of safety and the environment (director) is delegated by the President and Representative Director to supervise the division as the chief officer involved in safety, health, and the environment, and the Safety, Environment and Quality Assurance Department serves as the secretariat.

Safety & Environmental Protection Headquarters determines the Medium-term Management Plan, annual basic policy, and priority issues related to the safety and health environment, and then grasps and evaluates the results of safety and environmental audits, and maintains, reviews, and confirms the status of improvements to the safety, health, and environmental management systems. As a corrective action or review, the general manager of the division conducts a management review at the Safety & Environmental Protection Headquarters meeting and reflects it in the basic policy for the next fiscal year.

Within these systems, each Complex consistently pursues and works from top management to always give top priority to human safety.

In addition, we have established a Safety and Safety Assurance Advisory Committee that includes external experts to prevent large-scale accidents in Complex, and we are working to build more effective safety and security measures.

● Positioning of the Safety & Environmental Protection Headquarters within the corporate governance system and safety and environmental management system

FY2024 Safety and Environment Audit Results (unit: cases)

| Number of audits conducted | 11 | |

|---|---|---|

| Total number of complaints | 78 | |

| Major nonconformity | 0 | |

| Minor nonconformity | 4 | |

Risk management

Safety and Environmental Risk Assessment

To ensure safety and the environment throughout the company, we have established the "Guidelines for Risk Assessment Regarding Safety and the Environment," which lay out our basic approach to identifying hazards and procedures for risk assessment.

Based on these guidelines, we comprehensively identify potential hazards, including those in processes and equipment, conduct risk assessments, and take appropriate measures based on the results to reduce or eliminate risks.

In addition, for high-risk cases, Safety & Environmental Protection Headquarters Secretariat checks the management status and shares it with Management Committee to ensure progress on the action plan.

Safety and health management system

The Group utilizes the safety and health know-how it has cultivated through its experience to build and operate its own management system that complies with the international standard for occupational safety and health management systems (ISO45001) and the certification standards of the High Pressure Gas Safety Act.

We also strive for continuous improvement through internal audits and management reviews.

As of the end of June 2025, 10 domestic and overseas Complex will have obtained ISO 45001 certification.

Natural disaster risk management guidelines

Under the guidance of Safety and Safety Assurance Advisory Committee, we have revised our earthquake countermeasures, such as strengthening facility structures, that we have implemented since fiscal 2005, to reflect new thinking and to include measures against storm surges and typhoons in fiscal 2021. Based on this guideline, we have since been examining specific issues, such as measures against major typhoons and seismic evaluation and countermeasures from the perspective of BCP for anticipated earthquakes.

Metrics and targets

Initiatives

Our Group's Safety, Health and Environment Performance

●Idemitsu Group Safety and Environmental Performance for FY2024

|

|

|

|---|---|

|

|

|

|

|

|

-

Cases where the regulatory standards set out in environmental laws and regulations were not met, and cases where the company met internally determined criteria

● Occupational safety performance

Accident-free efforts

Our company has set a goal of "zero accidents," and is working to achieve "zero serious accidents resulting in bodily injury." However, in fiscal 2024, there were 52 accidents resulting in time off work, including one fatal accident * (30 at our company and 22 at partner companies). We took the occurrence of fatal accidents very seriously and promptly established an accident investigation committee chairperson by an external expert. Based on the results of the investigation into the cause of the accident and the recommendations for preventive measures from recurring from the accident investigation committee, we are working to thoroughly implement measures to prevent recurrence and are making efforts to prevent similar incidents from occurring by utilizing the lessons learned from the accident.

-

In May 2024, during flange release work on a heat exchanger at a heavy oil desulfurization unit at our Chiba Complex, an industrial accident occurred, resulting in the death of one employee of a partner company and injuries to five people, including one of our own employees.

In fiscal 2025, we will continue our "challenge to eliminate accidents," thoroughly implement "rules to protect lives," and establish a culture where decisions are followed and enforced.

The "Rules for Saving Lives" prohibit five actions that pose a significantly high risk of causing serious personal injury.

Additionally, we hold company-wide case study meetings to review cases that resulted in serious injury or death or that could have resulted in serious injury or death, and are working to prevent serious injury or death from occurring in the first place or recurring.

Basic Policy for Safety, Health and Environment in 2025

We will continue our "challenge to eliminate accidents" and promote the following two issues as our top priorities.

■ The head office and Complex will work together to autonomously and reliably implement the PDCA cycle for the safety environment system.

■ By showing consideration for and encouraging colleagues, we will establish a culture in which people follow and make others follow the rules that have been decided, including the "rules for protecting lives."

As a result, the following three goals must be achieved:

"Zero serious accidents," "Zero serious accidents resulting in injury," and "Zero environmental abnormalities"

Safety and health initiatives

Strengthening the earthquake resistance of existing facilities

The Tokachi-oki earthquake in 2003 prompted the Group to establish Safety and Safety Assurance Advisory Committee. In addition, through activities such as the Facility Structural Reinforcement Study Group, which covers Refineries/Complexes, we have been evaluating and implementing measures against anticipated earthquake strengths that exceed the legal standards.

From fiscal 2020 onwards, we will utilize the government's subsidy program for strengthening our facilities and will be carrying out seismic assessments and measures against anticipated earthquakes at oil terminal in addition to Refineries/Complexes from the perspective of BCP *, and working to reinforce our facilities. Going forward, the Group will continue to consider and implement further earthquake resistance enhancements.

-

BCP is a business continuity plan created to minimize damage in the event of a disaster or other emergency, and to ensure business continuity and early recovery.

Strengthening LPG tank support structure (Tokuyama Complex)

Strengthening offshore piers to improve disaster reception capacity (Showa Yokkaichi Sekiyu Co. Yokkaichi Refinery)

Strengthening LPG tank support structure (Tokuyama Complex)

Strengthening offshore piers to improve disaster reception capacity (Showa Yokkaichi Sekiyu Co. Yokkaichi Refinery)

Strengthening LPG tank support structure (Tokuyama Complex)

Strengthening offshore piers to improve disaster reception capacity (Showa Yokkaichi Sekiyu Co. Yokkaichi Refinery)

Super certified Complex

As a measure to improve safety capabilities in light of the advancement of safety technology, our Group Refineries/Complexes are working on utilizing cutting-edge technology, advanced risk assessment, advanced education and training, etc. As a result, the following Refineries/Complexes have been certified as "Super Certified Complex" that are taking on advanced safety initiatives under the High Pressure Gas Safety Act.

・ Tokuyama Complex (certified on September 5, 2019)

・ Chiba Complex (certified on March 17, 2020)

・ Hokkaido Refinery (certified June 29, 2021)

・ Aichi Complex Minamihama District (certified on February 5, 2024)

・ Aichi Complex Kitahama District (certified on February 5, 2024)

・ Showa Yokkaichi Sekiyu Co. Yokkaichi Refinery (certified June 14, 2022)

In response to the aging of plants and the decline in skilled workers, Complex that are implementing advanced safety measures, such as utilizing IoT and big data, are being certified as "Super Certified Complex," and it is expected that this will contribute to improving safety throughout the industry. Certified Complex will be subject to streamlined voluntary safety regulations, which will lead to increased international competitiveness.

●Classification of Complex regarding security

|

|

|

|

|

|---|---|---|---|

|

|

(Operation is stopped and inspected once a year) |

(Period approved by the Minister) |

(period freely set by the business operator) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Utilizing advanced technology to ensure safety

We are verifying and introducing cutting-edge technologies across the entire company. Examples include the construction of an AI-based equipment corrosion diagnosis system, the development of AI-based equipment monitoring technology, the use of AI in boiler combustion control to suppress equipment fluctuations, cybersecurity measures, VR-based risk experience education, and practical simulators. We are introducing a variety of technologies tailored to the situation at each location.

National Safety Week Initiatives

For our company, whose philosophy of ensuring safety is to "ensuring people's safety as the top priority," the National Safety Week, which is held for the purpose of preventing industrial accidents, is a valuable opportunity to inspect workplace safety. Taking this opportunity, the President and CEO sends a message to all employees of our group, expressing his/her determination toward safety, and we are striving to ensure thorough compliance with the "rules for protecting lives" established by our company.

Internal safety award

●FY2024

| Award target | Award/award name | Achievement record | Award day | Record date |

|---|---|---|---|---|

| Idemitsu Retail Sales Co., Ltd. China Company | Accident-free record silver award |

3,200 days | April 12, 2024 | January 3, 2024 |

| Nippon Grease Co., Ltd. Yokohama Plant | Accident-free record silver award |

3,200 days | May 10, 2024 | January 3, 2024 |

| Sado oil terminal | Accident-free record bronze award |

2,200 days | May 27, 2024 | January 9, 2024 |

| Idemitsu Tanker Co., Ltd. APOLLO HARMONY | Accident-free record bronze award |

1,600 days | September 3, 2024 | March 24, 2024 |

| Idemitsu Unitech Co., Ltd. Chiba Factory | Accident-free record bronze award |

1,000 days | August 30, 2024 | April 11, 2024 |

| Idemitsu Unitech Co., Ltd. Mie Factory | Accident-free record bronze award |

1,000 days | August 30, 2024 | April 23, 2024 |

| Technology & Engineering Center | Accident-free record silver award |

3,500 days | January 9, 2025 | October 29, 2024 |

| Lubricants Research Laboratory | Accident-free record bronze award |

2.8 million hours | March 26, 2025 | November 14, 2024 |

| Oil Transportation Services Co., Ltd. | Accident-free record silver award |

3,200 days | March 27, 2025 | November 15, 2024 |

●FY2023

| Award target | Award/award name | Achievement record | Award day | Record date |

|---|---|---|---|---|

| Idemitsu Electronic Materials Korea Co., Ltd. | Accident-free record gold medal |

3,000 days | October 16, 2023 | June 17, 2023 |

| Narita hydrogen station | Accident-free record bronze award |

3,000 days | September 25, 2023 | June 17, 2023 |

| Nagase & Co., Ltd. | Accident-free record bronze award |

3,000 days | September 26, 2023 | June 17, 2023 |

| Okinawa oil terminal | Accident-free record bronze award |

1,600 days | November 30, 2023 | July 24, 2023 |

| Idemitsu Oita Geothermal Co., Ltd. Takigami Complex | Accident-free record bronze award |

3,000 days | November 16, 2023 | June 17, 2023 |

| Coal & Environment Research Laboratory | Accident-free record bronze award |

3,000 days | October 25, 2023 | August 12, 2023 |

| Idemitsu Plantec Chiba Co., Ltd. | Accident-free record bronze award |

2.8 million hours | November 16, 2023 | August 7, 2023 |

| Idemitsu Lube India Patalganga Factory | Accident-free record silver award |

4.6 million hours | October 5, 2023 | August 23, 2023 |

| Idemitsu Tanker Co., Ltd. APOLLO ENERGY | Accident-free record bronze award |

1,600 days | January 26, 2024 | September 2, 2023 |

| Kishiwada oil terminal | Accident-free record bronze award |

2,200 days | December 7, 2023 | October 15, 2023 |

| Idemitsu Lubricant (China) Co., Ltd. Tianjin Factory | Accident-free record bronze award |

2.3 million hours | January 16, 2024 | August 16, 2022 |

| Idemitsu Vietnam Gas Development Co., Ltd. | Accident-free record bronze award |

1.5 million hours | March 28, 2024 | October 6, 2023 |

| Idemitsu Electronic Materials (China) Co., Ltd. Chengdu Factory | Accident-free record bronze award |

1,400 days | February 1, 2024 | October 25, 2023 |

| Idemitsu Lube Techno Co., Ltd. Moji Complex | Accident-free record silver award |

3,200 days | March 25, 2024 | January 3, 2024 |

| Idemitsu Tanker Co., Ltd. IDEMITSU MARU | Accident-free record silver award |

3,200 days | January 26, 2024 | January 3, 2024 |

| Idemitsu Tanker Co., Ltd. APOLLO DREAM | Accident-free record silver award |

3,200 days | January 26, 2024 | January 3, 2024 |

●FY2022

| Award target | Award/award name | Achievement record | Award day | Record date |

|---|---|---|---|---|

| Musselbrook Mine (Australia) | Accident-free record silver award |

2,400 days | April 1, 2022 | December 7, 2021 |

| Idemitsu Bulk Terminal Co., Ltd. | Accident-free record bronze award |

1,200 days | July 27, 2022 | March 19, 2022 |

| Takamatsu Asphalt Base | 2022 Excellent Safety Activities Complex | ー | September 30, 2022 | ー |

| Idemitsu Lub Techno Indonesia Karawang Factory | Accident-free record silver award |

4.6 million hours | October 24, 2022 | April 22, 2022 |

| Idemitsu Plantech Tokuyama Co., Ltd. | Accident-free record bronze award |

2.8 million hours | December 21, 2022 | August 19, 2022 |

| SDS Co., Ltd. Biotech Tsukuba Research Institute | Accident-free record bronze award |

1,600 days | December 23, 2022 | August 12, 2022 |

| Idemitsu Retail Sales Co., Ltd. Kansai Company | Accident-free record bronze award |

1,600 days | ー | October 1, 2022 |

| Idemitsu Engineering Vietnam | Accident-free record bronze award |

1.5 million hours | January 20, 2023 | June 30, 2022 |

| Hakodate oil terminal | Accident-free record bronze award |

2,200 days | February 3, 2023 | December 5, 2022 |

| Tokuyama Complex | Accident-free record gold medal |

5.7 million hours | February 9, 2023 | November 12, 2022 |

| Fukuoka oil terminal | Accident-free record bronze award |

2,200 days | February 10, 2023 | October 2, 2022 |

| Materials Development Center, Production Technology Development Center | Accident-free record bronze award |

1,600 days | March 1, 2023 | November 16, 2022 |

| Idemitsu Unitech Co., Ltd. Product Development Center | Accident-free record silver award |

2,800 days | March 1, 2023 | January 29, 2022 |

| Prarock Asia (Thailand) | Accident-free record silver award |

2,400 days | March 29, 2023 | December 16, 2022 |

Safety education

Company-wide education

During new employee training, we use videos of past serious accidents at our company to educate employees about safety. Safety first is the foundation of our company's management, and we strive to keep our employees aware of this at all times.

Education hosted by Safety & Environmental Protection Headquarters

Safety & Environmental Protection Headquarters, conducts education and training to cultivate leadership skills to autonomously promote the PDCA cycle for safety and environment management in each department and office.Basic training is conducted for key persons in each department and office to educate them on their roles based on company regulations and the basics of safety and environment management, as well as training to improve safety and environment management capabilities (see table below) (a total of 11 training sessions were held in fiscal 2024).

●2024 Educational Training Participation Results

| Total number of participants (people)Total number of participants (people) |

Total training time (hours) | ||

|---|---|---|---|

| Basic training for newly appointed safety and environment managers | Common lectures | 210 | 420 |

| Safety and environmental manager level-up training | Common lectures | 204 | 816 |

| Safety and environmental auditing skills improvement training | Common lectures | 83 | 83 |

| exercises | 71 | 213 | |

| Environmental management ability improvement training | Common lectures | 141 | 282 |

| exercises | 126 | 378 | |

| Safety and Environmental Risk Assessment Training | Common lectures | 78 | 156 |

| exercises | 19 | 95 | |

| Training to improve accident and failure analysis skills | Common lectures | 56 | 56 |

| exercises | 10 | 70 | |

| Total | 998 | 2,569 | |

Practical firefighting training

[Disaster prevention training for personnel at Refineries/Complexes]

In the unlikely event of a fire or explosion, it is extremely important to carry out initial firefighting activities and prevent the spread of fire in order to minimize damage inside and outside Refineries/Complexes. Therefore, recognizing the importance of accumulating practical training based on basic fire prevention and extinguishing theory, we focus on training disaster prevention personnel. For example, we teach the basics of disaster prevention activities in classrooms, and conduct training on the handling of equipment and hose deployment using actual machines according to a plan. In particular, at Hokkaido Refinery, Chiba Complex, and Aichi Complex, we also conduct flame contact training using actual fire training areas.

Comprehensive disaster prevention training at Chiba Complex (September 2019)

Large tanker emergency unberthing training at Aichi Complex (September 2019)

Comprehensive disaster prevention training at Chiba Complex (September 2019)

Large tanker emergency unberthing training at Aichi Complex (September 2019)

Comprehensive disaster prevention training at Chiba Complex (September 2019)

Large tanker emergency unberthing training at Aichi Complex (September 2019)

[Live fire training at Niigata Disaster Prevention Training Center]

The Safety, Environment & Quality Assurance Department has the Niigata Disaster Prevention Training Center, which continuously accepts many trainees every year, not only from within the company but also from various companies in the industry. The training assumes fires that occur at specific facilities at Complex, and aims to strengthen Complex 's initial fire extinguishing system by acquiring initial fire extinguishing methods appropriate for the nature of oil fires through theory (classroom learning) and practice (actual fire training).

Education and training hosted by the Safety and Technical Training Center Manufacturing & Technology Department

[Development of manufacturing equipment operators]

The Safety and Technical Training Center provides training to develop production site operators as production engineers (PEs). PEs are engineers in the operations Refineries/Complexes who have a logical understanding of processes, equipment, and systems, and who can make comprehensive decisions based on their interrelationships, ensuring the safety of our Refineries/Complexes by optimizing their safe and efficient operations.

[Strengthening safety education]

The Safety and Technical Training Center is working to strengthen safety education. For example, we provide training for supervisors and deputies (assistant supervisors) to improve their ability to make decisions in emergencies and other situations. This training is based on in-house development and is specialized for practical operations. Trainees form operating teams and conduct the training using a training plant modified from a desulfurization unit that was actually operated at Tokuyama Complex. Participants engage in realistic training, including reporting abnormalities at night or on holidays, initial response, emergency shutdowns, disaster prevention activities, and evaluation and analysis as the situation progresses. We also provide safety management training for newly appointed technical Manager and section chiefs at Refineries/Complexes and affiliated refining companies. This training is divided into basic and follow-up sessions. Participants review safety management key points in the basic session, and clarify problem recognition and action plans for fostering a safety culture in the follow-up session. In addition, as part of experiential training for government and organizations, and human resource development in collaboration with the local community, we provide our danger experience equipment and VR to support lectures held by the Keiyo Human Resources Development Association, and have received high praise from outside the company.

Tokuyama Complex Training Plant

Safety awareness training course

Tokuyama Complex Training Plant

Safety awareness training course

Tokuyama Complex Training Plant

Safety awareness training course

Utilization of external education

[Training for top management]

To prevent serious industrial accidents, it is crucial that top management, such as Refinery and Complex have a strong sense of safety and promote accident prevention measures under their strong leadership. Therefore, oil and chemical industry organizations and related companies, including our company, appealed to an external training center to emphasize the importance of fostering safety awareness among top management. This led to the center hosting a special lecture, "Future Safety and the Role of Top Management," which has been held regularly since 2016. This year, we are planning to hold a "Future Safety Management Forum," where top management from the oil and chemical industries in the petroleum complex, which is undergoing a period of major change, will exchange opinions across company and industry boundaries. At our company, on-site Refinery and Complex and top management from the headquarters' Manufacturing & Technology Department take this lecture every year, strengthening our industrial safety leadership alongside Refinery and plant managers from other companies, primarily those located near the center.