Circular society

Basic approach

The Idemitsu Group believes in creating a recycling-oriented society by transforming the traditional society of mass production, mass consumption, and mass disposal, and creating a society that suppresses the consumption of natural Resources and reduces the burden on the environment as much as possible. I believe this is the goal of realization. Renewable Resources should be reused within the limits of their renewable capacity, and non-renewable Resources should be consumed in the most effective manner, while over the long term, their use should be restrained while other renewable resources should be used. We are promoting various initiatives so that we can shift to Resources.

Strategy

Based on the technology possessed by each department, our group is conducting a cross-company study aimed at realizing a sustainable circular business by reusing renewable Resources as much as possible and incorporating them into our business supply chain. We are making progress. Specifically, we are working on plastic recycling and, from a long-term perspective, carbon recycling, which treats CO₂ as Resources.

Risk management

Initiatives

Recycling of Used Plastics

In April 2023, we decided to invest in oil chemical recycling equipment that uses used plastic as raw material. We have established Chemical Recycle Japan Co., Ltd. (hereinafter referred to as CRJ), a joint venture with Kankyo Energy Co., Ltd., which has been working jointly to establish technology for oil converting equipment, to produce produced oil from used plastics. We aim to start commercial operations.

CRJ will use its proprietary technology to produce oil from the collected used plastic, and we will produce "renewable chemicals" as an alternative material to crude oil. By producing plastic products using these "renewable chemicals" as raw materials, we realize Resources circulation. After establishing a business model in the area adjacent to Chiba Complex, we plan to install oil converting equipment at other group Refineries/Complexes, and move forward with large-scale business development targeting used plastics nationwide.

Supporting Gunpla through chemical recycling

The Gundam series plastic model "Gunpla" sold by Bandai Namco Group has been using polystyrene from group company PS Japan Co., Ltd. (PSJ) since its launch. “Gunpla” will celebrate its 40th anniversary in 2020 and is a huge hit with over 700 million units sold. PSJ is participating in the "Gunpla Recycling Project" launched by the Bandai Namco Group in 2021 in terms of chemical recycling. This project aims to collect the ''runners'' that form the frame of ''Gunpla'' and commercialize plastic models through chemical recycling, the first in the world.

Chemical recycling technology is a cutting-edge technology that thermally decomposes used polystyrene products and returns them to their raw material, styrene monomer, and PSJ will continue to establish this technology through repeated demonstration experiments.

Complying with the Act on Promotion of Resources Circulation Related to Plastics

Based on the "Act on Promotion of Plastic Resources Recycling, etc." that came into effect on April 1, 2022, our waste plastic emissions for each fiscal year (2021 and 2022) are as follows.

| FY2022 waste plastic emissions |

|

|---|---|

| FY2021 waste plastic emissions |

|

In the "Plastic Resources Circulation Strategy" formulated by the government in 2019, one of the milestones is to "reduce cumulative one-way plastic emissions by 25% by 2030," and in order to achieve this, waste plastic We must reduce emissions by approximately 3% per year on average over the period. To this end, we will take the following actions:

1. Try to use it for a long time.

2. Curb excessive use.

3. When disposing of plastic products, try to continue using healthy parts.

Additionally, our company conducts employee education on the ``Act on Promotion of Plastic Resources Recycling'' during environmental management skill improvement training every year.

Solar panel recycling

The number of used solar panels is expected to increase rapidly from the 2030s. Solar Frontier Co., Ltd., a member of our group, is developing recycling technology for solar panels, aiming to achieve a material recycling rate of over 90% and commercialize it in fiscal 2024.

All-solid-state lithium battery recycling

With the spread of EVs, the supply and demand for raw materials such as lithium is expected to tighten over the long term, and we are aiming to improve the added value of all-solid lithium battery value chain in the future by considering recycling schemes for waste batteries.

Carbon recycling

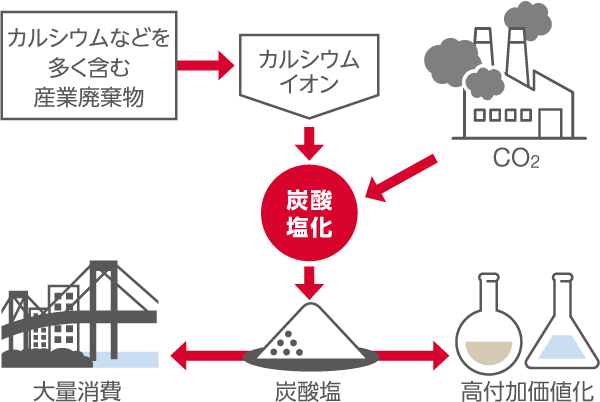

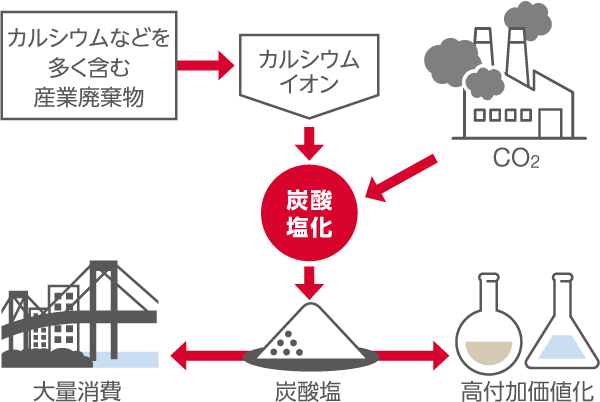

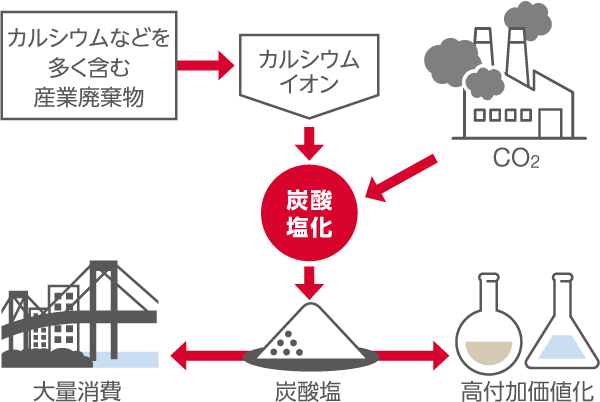

Carbon recycling is an initiative that treats CO₂ as a carbon Resources (carbon) and generates various carbon compounds from CO₂ to reuse it in chemicals, fuels, minerals, etc. Our company is currently conducting research and development on carbonation and CO₂ electrolytic reduction technologies.

Carbonation

With the participation of Ube Industries, Ltd., JGC Holdings, Inc., JGC Corporation, and multiple universities, we are working as an industry-academia collaboration initiative to utilize industrial waste containing a large amount of calcium, etc., to produce thermal power plants. and CO₂ emitted from factories. In 2019, we established the CCSU (Carbon dioxide Capture and Storage with Utilization) Study Group, which aims to develop new technologies to convert carbon dioxide into Resources. The country is releasing CO₂ as a measure against global warming. While promoting the development of technologies such as collection, we are using industrial waste containing a lot of calcium to reduce CO₂ emissions. We are working on the development of a new technology that reacts with carbonate to create high added value.

In July 2020, "Research and development of accelerated carbonation process using calcium in industrial waste such as waste concrete" was selected as a NEDO research and development contract project. The contract period for this project is five years from FY2020 to FY2024. Calcium, which is a raw material, will be extracted from industrial waste containing a lot of calcium, such as waste concrete, and CO₂ in exhaust gas will be extracted. We will develop technology aimed at the practical application and widespread use of a process that reacts with and immobilizes. In addition, in order to increase the efficiency of calcium extraction and carbonation, we will conduct tests and evaluations of accelerated carbonation technology, establish the technology while optimizing the entire process, and CO₂ We will evaluate the reduction effect.

In response to this project's selection, CO₂ emissions from power plants and factories will be reduced. In addition to developing new technologies related to the immobilization of biochemicals through collaboration between industry, academia, and government, we will accelerate efforts toward provide for society in a wide range of areas, from raw material procurement to application development.

CO₂ Resources recovery

To date, we have succeeded in directly synthesizing hydrocarbons and alcohols from water and CO₂ using gas diffusion electrodes using proprietary catalysts. Conventionally, most methods involved reacting CO₂ once dissolved in water, but this method is unique in that it uses a gas diffusion electrode that allows CO₂ to react directly as a gas. In the CO₂ Resources recovery technology (electrolytic reduction technology) using this gas diffusion electrode, we are proceeding with development to further increase the CO₂ processing capacity by improving the performance, lowering the cost, eliminating precious metals, and extending the life of the electrode catalyst. I am.

We will further advance our research and development of CO₂ electrolytic reduction technology using this gas diffusion electrode, and establish a technology that uses renewable energy to produce useful substances such as chemicals and fuels from CO₂ with high efficiency. We aim to contribute to achieving carbon neutrality in 2050 by reusing CO₂.