Circular society

Basic approach

The Idemitsu Group believes that the purpose of realizing a recycling-oriented society is to reform the society of mass production, mass consumption, and mass waste, while curbing the consumption of natural Resources and forming a society that reduces the burden on the environment as much as possible. We are promoting various initiatives to reuse renewable Resources within the scope of their regeneration capacity, and to consume non-renewable Resources in the most effective way possible, while curbing their use over the long term and shifting to other renewable Resources.

Policy

Circular Economy Guideline

1. Objective

Our company group believes in creating a recycling-oriented society by transforming the traditional society of mass production, mass consumption, and mass disposal, and creating a society that suppresses the consumption of natural Resources and reduces the burden on the environment as much as possible. And our company is striving to reduce the environmental impact by reducing the amount of waste generated and promoting the reuse of raw materials and the use of recycled materials from the perspective of effective Resources use.

Within the Idemitsu Group's sustainability policy, there is a statement that states, "We will promote innovative technological development, proactively reduce environmental risks associated with our business activities, and contribute to the conservation of the natural environment and the realization of a circular society." In addition to complementing the above sustainability policy, this guideline establishes guidelines for further implementation of circular economy activities.

2. Main Text

(1) In all existing and future business activities, we will promote the efficient use of resources, minimize waste, and encourage recycling and reuse, thereby reducing environmental impact and ensuring stable procurement of raw materials.

(2) Taking into account economic viability, we will create a framework that incorporates demand while making recycling and other costs feasible, and practice the circular economy.

(3) We aim to consider recycling and reuse from the product design stage and strive to reuse waste as new resources.

(4) Achieving this requires collaboration with related companies and suppliers, including in terms of technology and raw material procurement, and we will promote it based on collaborative partnerships.

(5) We will not only educate and raise awareness among employees but also among stakeholders, aiming to foster understanding and widespread adoption of the circular economy.

Strategy

Based on the technology possessed by each department, our group is conducting a cross-company study aimed at realizing a sustainable circular business by reusing renewable Resources as much as possible and incorporating them into our business supply chain. We are making progress. Specifically, we are working on plastic recycling and, from a long-term perspective, carbon recycling, which treats CO₂ as Resources.

Risk management

Metrics and targets

Quantitative target

| oil |

|

|---|---|

| Used plastic recycling |

|

In formulating the above quantitative targets, we are participating in Circular Partners, a partnership established by the Ministry of Economy, Trade and Industry to promote collaboration between industry, government and academia with the aim of realizing a circular economy.

The initiative was established based on the "Growth-oriented Resources Autonomous Economy Strategy" formulated by the Ministry of Economy, Trade and Industry in March 2023. Because realizing a circular economy is difficult for individual companies to achieve alone, it requires collaboration and expansion of efforts among stakeholders throughout the entire lifecycle, and this initiative is part of that effort.

Initiatives

Chemical recycling of used plastics

We are accelerating our efforts to build a Resources recycling supply chain.

In April 2023, we decided to invest in an oil-to-chemical recycling facility that uses used plastics as raw material, and at the same time established Chemical Recycle Japan Co., Ltd. (hereinafter referred to as CRJ) as a subsidiary of our company. CRJ is currently constructing an oil-to-chemical recycling facility in an area adjacent to our Chiba Complex that will process 20,000 tons of used plastics per year, with the aim of commencing commercial operation in 2026.

CRJ will use its proprietary technology to produce CR oil * equivalent to crude oil from recovered used plastics, which will then be processed in our oil refining and petrochemical facilities to be Resources into Basic Chemicals. By quickly establishing a new production system for "chemically recycled chemicals," we will contribute to the realization of Resources circulating society.

After establishing a business model in the area adjacent to Chiba Complex, we plan to install oil chemical recycling equipment at other Group Refineries/Complexes, and to proceed with large-scale business expansion targeting used plastics nationwide.

-

CR oil: Chemically recycled oil, produced by turning used plastic into oil.

Supporting Gunpla through chemical recycling

The Gundam series plastic model "Gunpla" sold by Bandai Namco Group has been using polystyrene from group company PS Japan Co., Ltd. (PSJ) since its launch. “Gunpla” will celebrate its 40th anniversary in 2020 and is a huge hit with over 700 million units sold. PSJ is participating in the "Gunpla Recycling Project" launched by the Bandai Namco Group in 2021 in terms of chemical recycling. This project aims to collect the ''runners'' that form the frame of ''Gunpla'' and commercialize plastic models through chemical recycling, the first in the world.

Chemical recycling technology is a cutting-edge technology that thermally decomposes used polystyrene products and returns them to their raw material, styrene monomer, and PSJ will continue to establish this technology through repeated demonstration experiments.

Compliance with the Act on Promotion of Resources Recycling of Plastics

Based on the Act on Promotion of Resources Circulation Related to Plastics, which came into effect on April 1, 2022, our amount of waste plastic emissions from fiscal 2021 onwards is as follows.

| FY2024 |

|

|---|---|

| FY2023 |

|

| FY2022 |

|

In the "Plastic Resources Circulation Strategy" formulated by the government in 2019, one of the milestones is to "reduce the cumulative amount of single-use plastic emissions by 25% by 2030," and in order to achieve this, we must reduce waste plastic emissions by an average of about 3% per year over the period. To achieve this, we will work on the following implementation items.

1. Try to use it for a long time.

2. Curb excessive use.

3. When disposing of plastic products, try to continue using healthy parts.

Every year, we educate our employees about the Act on Promotion of Resources Recycling of Plastics as part of our environmental management capability improvement training.

Solar panel recycling

The amount of used solar panels is expected to increase sharply from the 2030s. Solar Frontier K.K., a member of our group, is preparing to promote the recycling of solar panels on a nationwide scale.

All-solid-state lithium battery recycling

As EVs become more widespread, the supply and demand of raw materials such as lithium is expected to become tight in the long term. Through the investigation of a waste battery recycling scheme, we aim to increase the added value of all-solid lithium battery value chain in the future.

Collaboration towards realizing a recycling-oriented society

Collaboration with various companies, local governments, universities, and other research institutions is essential to realizing a recycling-oriented society, and we are engaged in a variety of collaborations as shown in the table below.

| Collaboration name | Overview | Goals and results | Collaborators | |

|---|---|---|---|---|

| ① | Promoting the use of wood at eco-friendly service station" apollostation Type Green" | Starting in November 2022, environmentally friendly service stations will begin operating that use domestically produced wood for canopies and buildings. | CO₂ reduction of approximately 80 tons per year | Meiken Kogyo Co., Ltd. |

| ② | Selling Idemitsu Renewable Diesel (IRD) and Idemitsu Biodiesel 5 (IBD5), low-carbon fuels derived from waste cooking oil | Selling IRD and IBD5 for vehicles and heavy machinery, aiming to reduce CO₂ emissions throughout the supply chain | IRD: 100% reduction in CO₂ emissions IBD5: Reduce CO₂ emissions by 5% *CO₂ emission reduction amount under domestic legislation |

Meitetsu Bus Co., Ltd., Obayashi Corporation/Kajima Corporation, Air Water Inc. |

| ③ | provide for society of synthetic calcium carbonate made from CO₂ and concrete waste | Fixing CO₂ in exhaust gas to produce calcium carbonate contributes to reducing CO₂ emissions and recycling Resources | Synthetic calcium carbonate with a CO₂ fixation rate of 20% provide for society as a raw material for industrial materials such as asphalt. | Nippon Concrete Industry Co., Ltd., and others |

| ④ | Investing in and considering commercialization of startups with technologies that contribute to the effective utilization of organic waste and Resources recycling | Idemitsu Americas Holdings, a wholly owned subsidiary of Idemitsu, has invested in a Canadian startup with technology to quickly compost organic waste, with the aim of acquiring knowledge and know-how in Resources recycling business. | Promoting verification for commercialization, including domestic demonstrations Pursuing future commercialization possibilities through collaboration with domestic and international players | Anaconda Systems |

Smart Eco Station Kanokodai SS

IBD5 logo

IRD logo

Synthetic calcium carbonate (Calcabo®)

Smart Eco Station Kanokodai SS

IBD5 logo

IRD logo

Synthetic calcium carbonate (Calcabo®)

Smart Eco Station Kanokodai SS

IBD5 logo

IRD logo

Synthetic calcium carbonate (Calcabo®)

Carbon recycling

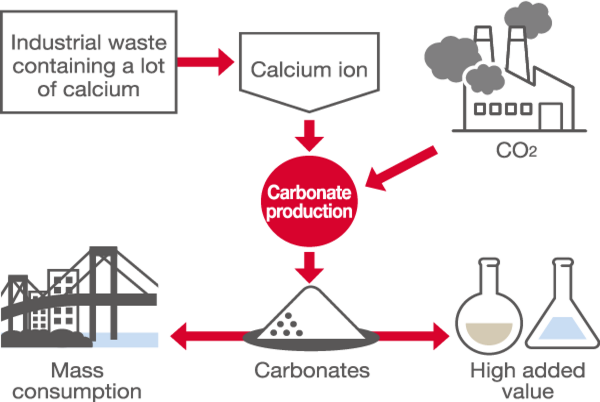

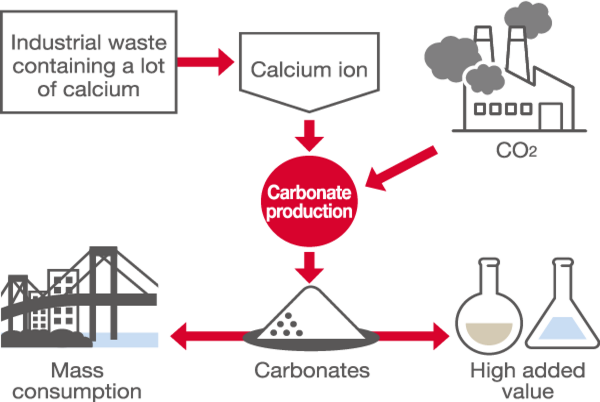

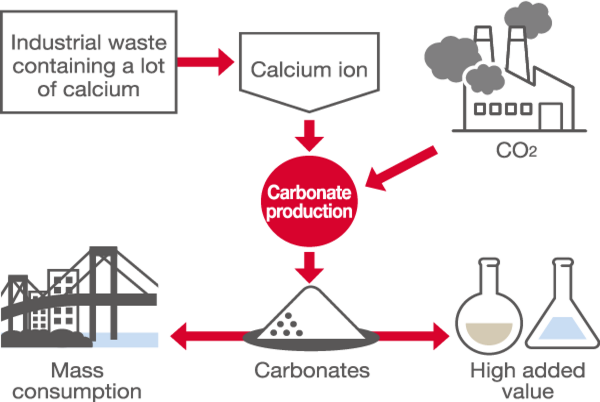

Carbon recycling is an initiative that treats CO₂ as a carbon Resources (carbon) and generates various carbon compounds from CO₂ to reuse it in chemicals, fuels, minerals, etc. Our company is currently conducting research and development on carbonation and CO₂ electrolytic reduction technologies.

Calcium carbonate technology

We are working on developing technology to convert CO₂ into calcium carbonate and implementing it in provide for society. Specifically, we use unused calcium-containing waste as a raw material and synthesize and Resources calcium carbonate through a chemical reaction with CO₂. By expanding this to a variety of applications such as asphalt paving and concrete materials, we aim to achieve CO₂ fixation, effective utilization of waste, and Resources circulation.

In 2023, through joint research with Nippon Concrete Industries Co., Ltd., we established a manufacturing process for synthetic calcium carbonate (registered trademark Calcarbo®) that utilizes concrete waste. Furthermore, in March 2025, we completed the construction of actual manufacturing facilities within our concrete factory, establishing a full-scale mass production system. This facility uses concrete sludge, which was previously treated as industrial waste, and CO₂ in the boiler exhaust gas that serves as a heat source for the concrete factory, as raw materials.

We are also making steady progress in our efforts to put Calcarbo™ to provide for society. In collaboration with road companies, we plan to install Calcarbo™-mixed asphalt pavement at our company's Complex, public facilities, and general roads by August 2025, and we are continuing to evaluate its performance. In addition, we are working with general contractors to prototype and evaluate Calcarbo™-mixed concrete, with construction at actual construction sites scheduled for the near future.

We will continue to actively promote the diversification of raw materials and the expansion of product applications, contributing to the creation of a sustainable, recycling-oriented society.

CO₂ Resources

To date, we have succeeded in directly synthesizing hydrocarbons and alcohols from water and CO₂ using gas diffusion electrodes using proprietary catalysts. Conventionally, most methods involved reacting CO₂ once dissolved in water, but this method is unique in that it uses a gas diffusion electrode that allows CO₂ to react directly as a gas. In the CO₂ Resources recovery technology (electrolytic reduction technology) using this gas diffusion electrode, we are proceeding with development to further increase the CO₂ processing capacity by improving the performance, lowering the cost, eliminating precious metals, and extending the life of the electrode catalyst. I am.

We will further advance our research and development of CO₂ electrolytic reduction technology using this gas diffusion electrode, and establish a technology that uses renewable energy to produce useful substances such as chemicals and fuels from CO₂ with high efficiency. We aim to contribute to achieving carbon neutrality in 2050 by reusing CO₂.