From 1989 through 1993, a string of accidents involving large tankers occurred all around the world. Among others the one that took place in Alaska in 1989 caused by a stranded VLCC was regarded as one of the worst oil spill disasters in history. The oil spill inflicted irreparable damage on one of the USA's most cherished seabird and fish sanctuaries in Prince William Sound.

Once an accident involving a large tanker occurs, not only tanker owner or management company, but the cargo owner (importer of crude oil) cannot be exempt from responsibility for compensation, and liability for pollution and destruction of environment will cause fatal damage to the company.

Following this trend, the Idemitsu group companies established a section responsible for making judgements on the applicability of ships in relation to all of their business, and launched the Idemitsu Vetting Service on October 1, 1993.

Idemitsu Ship Vetting Service -Securing Safety at the Border

In recent years as global environmental issues are coming to the front, oil majors have been raising the standards of screening tankers year after year, and making every effort to select quality ships. Idemitsu also has put into practice a system to select tankers operated in group transportation. We will introduce a safety vetting system for tankers developed by Idemitsu Tanker Co.,Ltd.

History of Idemitsu Ship Vetting Service

Establishment of Inspection System

In 1993 OCIMF (Oil Companies International Marine Forum), an association of oil companies, established SIRE (Ship Inspection Report Programme) to make uniform safety management standards and to share information. Up until then inspection during cargo work had been carried out in accordance with the safety management procedure of each oil company, which laid a heavy burden on each ship.

The amount of information on ship inspection that each company obtained was also limited.

The establishment of SIRE helped rectify these situations. It has been said that the entire philosophy of SIRE was based on the motto, "Safety should be a common concern for all companies in the industry. Therefore companies can develop cooperative relationships when it comes to safety issues even if they are competitive to each other in business." As a matter of fact, once a company is involved in an oil pollution casualty which causes serious damage to society, the entire industry will be placed under unfavorable public scrutiny. Expenses required for disposing oil spill will be drawn from the funds created by oil companies worldwide.

SIRE includes a system to evaluate the capability of ship management companies, ship equipment such as navigation, communication, mooring, main deck, pump room, cargo control room, engine and steering compartments and the accommodation, and ships' crew. In actual ship inspection, each inspector who has experience of a tanker carries out several inspections per year on a ship to evaluate over four hundred items, and sends the results to the host computer in London. SIRE member companies can obtain any necessary data from the host computer.

Outline of Vetting

Idemitsu Vetting Service consists of executing prior examination on ship owners, management companies and performance of ships engaged in the Idemitsu group transportation; making judgements on applicability of ships and monitoring overall charter operations for possible risk to the group.

Specifically, the service helps the company make judgements on the basis of various information such as "assessment of ship owners and ship management companies," "SIRE, CDI(Chemical Distribution Institute) reports," "casualty record," "terminal feedback," and "crew matrix." For instance, most ship owners are reluctant to disclose reports of any deficiencies found on ship equipment. The vetting service will not overlook such indiscretions. Any malfunctions or defects, if not corrected, will relentlessly result in a decision of "no acceptance." A ship owner may end up losing his business chance if he fails to remedy a defect that is found during ship inspection.

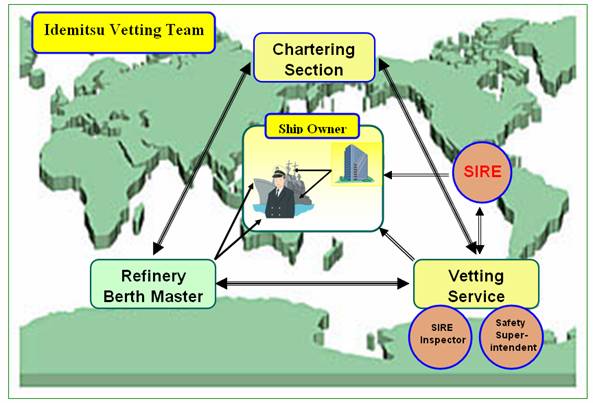

With each chartering section of Idemitsu group working as a contact, the vetting service secures safety at the border through the network consisting of the vetting service team of Idemitsu Tanker, berth masters of each oil refinery, SIRE inspectors and safety superintendents.

Idemitsu Vetting Network

Chartering Section

The chartering section serves as a contact for charter contracts. They make an inquiry to the vetting service section and berth master as to the applicability of ships, and make arrangements for chartering ships.

Vetting Service

Specialized staff who possess expertise and experience in tankers take the lead to collect information on ship equipment and safety, and manage such information. Their task consists of

- To make judgements on acceptance of charter (vetting)

- To carry out inspection and collect data (registering tanker inspection reports in the common system)

- To follow up decisions of acceptance with dispatching cargo handling safety superintendents and checking of ships before port call

- To follow up after acceptance (following up of ships with trouble, and supervising ship owners)

- To organize safety related meetings

Vetting service in progress

SIRE Inspector

SIRE inspectors are specialists recommended by OCIMF submitting member companies, and only those who hold qualifications required by SIRE can be appointed. In addition to in-house inspectors, Idemitsu deploys exclusively assigned inspectors in the territories both domestic and overseas covering the world.

Data obtained through ship inspection will be accumulated.

Berth Master

Berth masters have experience with tankers and are assigned to the refineries and factories of Idemitsu group. Their tasks are

- To make judgements on acceptance or rejection in terms of hardware

- To judge suitability of ships' arrival at and departure from pier in consideration of weather forecasts and conditions of refineries

- To give instructions concerning pier work on ships' arrival and departure

- To ensure safe operation in cargo handling

- To prepare, approve and receive documents concerning acceptance operation

- To respond to and handle trouble that occurs during mooring as well as ships' arrival at and departure from pier

Safety Superintendentity, and mooring equipment.

Safety superintendents are supervising to ensure safety. Specifically they strive to improve safety of tankers at berth and efficiency of cargo handling. They also check the conditions of bridge, deck, cargo space, pump room, and other important equipment such as nautical instruments, fire protection facility, and mooring equipment.

Cargo handling supervised by a safety superintendent

One article stated, "we all know it is impossible to eliminate accidents altogether. However, we must strive to make the possibility of accidents minimal." In order to minimize the possibility of accidents, it is not enough for ship owners and ship management companies to make efforts, but it is imperative that we cultivate an eye to evaluate safety issues objectively from the standpoint of a disinterested party. Working as a third party's eye and making use of all available resources of the network, “Idemitsu Ship Vetting Service” intends to continually monitor all ships entering Idemitsu terminals to prevent accidents at the border.