CALP PPS

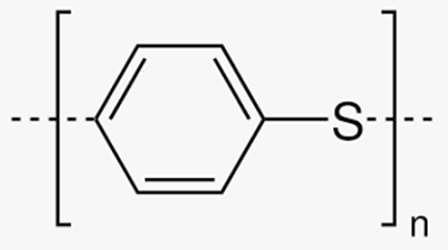

Polyphenylene Sulfide Resin (PPS)

Polyphenylene sulfide (PPS) resin is a crystalline thermoplastic with a flexible structure consisting of alternating bonds of benzene rings and sulfur atoms. PPS has a high melting point of 290°C, a deflection temperature under load (DTUL) of 260°C or higher for fiber-reinforced grades, and heat resistance that can withstand long-term use at 200°C or higher.

PPS also has chemical resistance and self-extinguishing properties comparable to those of fluorocarbon resins, and exhibits high flame retardancy (UL94 V-0) without the use of flame-retardant additives. Additionally, PPS has good fluidity, enabling the blending of various fillers in high concentrations, and its composite materials feature high dimensional accuracy comparable to that of amorphous resins.

Properties of CALP PPS Composite Materials

We at IDEMITSU FINE COMPOSITES are developing functional grades through multiple composites with various fillers, focusing on the good fluidity of PPS and its compatibility with fillers.

In addition to standard grades containing glass fibers and general-purpose fillers, we also offer composite material grades specialized for precision molding capability, sliding properties (slipperiness), and thermal conductivity. We also have many grades with precision molding capability based on carbon-fiber reinforcement.

We will continue to develop products that can meet our customers’ “Wish to have.”