Aichi Complex | Safety initiatives

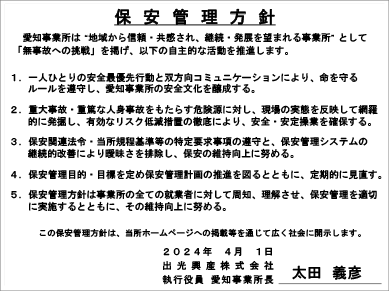

Security management policy

At our Complex, we carry out daily safety inspections of equipment, regularly shut down all equipment, and inspect each and every pipe for failures or abnormalities in an effort to maintain accident-free operations. Masu. We also actively conduct risk prediction activities and near-miss discovery activities, and are putting effort into preventing accidents before they occur.

In addition, earthquakes are one of the factors that lead to large-scale disasters, and our Complex has installed the latest simulation system. We have introduced an "automatic seismic isolation system'' that automatically stops equipment safely, a "tank earthquake damage prediction system'' that indicates the priority of tanks that should be inspected as soon as possible, and "simulator software'' that allows optimal tank disaster prevention activities. We are working to minimize the damage caused by disasters.

Safety first

We prioritize environmental and safety measures over production activities. At our office, under the basic policy of "safety first," we engage in activities to prevent problems with the participation of all employees. In addition, in preparation for the unlikely event of a fire or oil leak, we have disaster prevention equipment and a self-defense disaster prevention team, and we conduct thorough disaster prevention drills on a daily basis.

Main disaster prevention materials and equipment

| name | radix or quantity |

|---|---|

| Ordinary foam water cannon | 1 |

| Large chemical aerial water cannon vehicle | 2 |

| large chemical fire engine | 1 |

| Foam concentrate transport vehicle | 1 |

| fixed fire pump | 5 |

| oil fence | 3,583m (flotation type/portable type) |

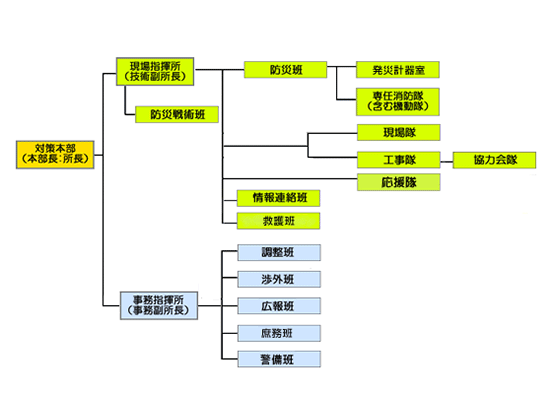

Self-defense disaster prevention team organization

Earthquake countermeasures at Aichi Complex

Chita City, where Aichi Complex is located, has been designated as an area for strengthening earthquake disaster prevention measures. At our facility, most of our equipment, including oil refining equipment and tanks, are designed to withstand earthquakes with a magnitude of 6 or lower that are expected to occur within the reinforced area.

We will continue to consider countermeasures, including soft measures, while seeking guidance from the government.

Enhance disaster prevention functions by deploying ordinary foam water cannons

In order to further enhance our firefighting capabilities in case of tank fires, etc., we have deployed ordinary foam water cannons, which have approximately twice the water spraying capacity of regular chemical fire engines. The maximum amount of water discharged is 5,700 liters per minute, and the maximum distance is approximately 100 m.

We have further strengthened our firefighting capabilities by deploying ordinary foam water cannons, etc., and we will continue to enhance our disaster prevention drills in order to prevent disasters and prepare for emergencies.

Large chemical aerial water cannon (left) and ordinary foam water cannon (right)

Large chemical aerial water cannon (back) and ordinary foam water cannon (front)

Radiation condition

Vehicle equipped with ordinary foam water cannon

flare stack

flare stack

Flare stacks are equipment that safely burns and safely discharges surplus and flammable gases that are generated when oil refinery equipment starts, stops, or adjusts operations. Our Complex handles large quantities of hazardous materials and high-pressure gas. If surplus flammable gas is released directly into the atmosphere, it may cause fires, explosions, or environmental pollution, so this is an important safety device to prevent this. In the past, the sight of a red-hot Refinery, but in recent years operations have been adjusted to ensure that no excess gas flows into the flare stack piping, reducing CO2 emissions and reducing global warming. It also contributes to prevention.

Security capability evaluation by a third party

In June 2022, we underwent a "security capability (safety foundation and safety culture) evaluation" by the Safety Capability Improvement Center, a specified non-profit organization. As a result, we received high evaluations in many indicators such as "safety design'' and "motivation''.

At the same time, we receive advice on indicators such as "process risk assessment" and "hazard recognition," and are working to further improve the level of safety.