Aichi Complex | Environmental initiatives

At our company, we aim to create all Refineries/Complexes Refineries/Complexes "beautiful, pollution-free,'' Refineries/Complexes beloved by local people.'' Based on this basic stance, our Complex has been set up as a green "park factory" with a green belt planted with 450,000 trees since the time of operation. In the green belt, you can see many small animals and birds, and it also acts as a buffer zone to prevent noise. We will continue to place great importance on harmony with the natural environment.

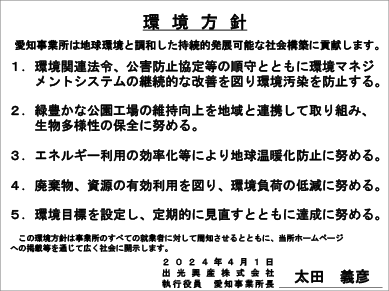

Environmental policy

Environmental Partnership/CLUB

"Environmental Partnership CLUB" is an organization centered on governments and businesses in Aichi, Gifu, and Mie prefectures that tackles environmental issues with the aim of building a recycling-oriented economic and social system, and has approximately 300 member companies. Masu.

Our office has been participating in the "Environmental Partnership CLUB" since its establishment.

Reduction of final disposal amount of industrial waste

As a result of our efforts to achieve the goal of "achieving zero emissions* in fiscal 2008,'' which is part of our Complex-wide medium-term environmental plan, we achieved this goal in 2004, three years ahead of schedule.

To achieve zero emissions, we have been promoting measures such as reducing the amount of waste through dehydration, reusing used catalysts, and Resources waste. Aiming to further reduce waste, we will promote activities from the viewpoints of the 3Rs: Reduce, Reuse, and Resources.

-

Definition of zero emissions: The amount of final (landfill) disposal of waste generated is 1% or less

Promotion of energy conservation

Aichi Complex began Complex as the newest Refinery in Japan, having been completed in 1975 after the first oil shock, and has been extremely energy efficient since its construction. In addition, all staff members have worked together to repeatedly improve energy efficiency.

Our goal is to reduce CO2 emissions from our own operations by 7.3 million tons by 2030, and we have begun considering energy-saving improvements and fuel conversion.

Environmental measures

Air pollution prevention measures

Flue gas desulfurization equipment that reduces SO x

As air pollutants, Complex generates sulfur oxides (SOx), nitrogen oxides (NOx), and soot from boilers, heating furnaces, etc. The generated SOx is reduced by removing it with flue gas desulfurization equipment. In addition, hydrogen sulfide generated from refining equipment such as heavy oil desulfurization equipment is processed in sulfur recovery processing equipment and recovered as sulfur.

Next, we are reducing NOx emissions by using low NOx burners, adopting two-stage combustion, and installing flue gas denitrification equipment. We also reduce soot and dust by removing it from the exhaust gas using electrostatic precipitators.

Through these reduction measures, we are complying with internal standards that are stricter than the Air Pollution Control Act and the pollution control agreements concluded with Aichi Prefecture and Chita City.

Water pollution prevention measures

Activated sludge treatment equipment

The water discharged from Complex equipment is treated using the coagulation sedimentation method, activated sludge treatment method, activated carbon treatment method, etc. In addition, after treatment, the wastewater is checked for hydrogen ion concentration (pH), nitrogen content, phosphorus content, chemical oxygen demand (COD), etc., according to the Water Pollution Control Law and pollution prevention agreements concluded with Aichi Prefecture and Chita City. We comply with in-house standards that are even stricter than our own. You can check the annual emissions from the environmental data below.

Furthermore, in fiscal 2011, we reinforced equipment to remove COD and phosphorus from wastewater, further reducing pollution.

Soil pollution prevention measures

The Soil Contamination Countermeasures Act went into effect in February 2003, making it mandatory to conduct a soil contamination investigation when a designated facility that uses hazardous substances is closed down or when the governor recognizes that there is a risk of health damage.

Although there was no obligation to investigate at our Complex, we conducted voluntary investigations of the premises from 2003 to 2008 based on the company-wide medium-term environmental plan and confirmed that there were no problems related to soil contamination. Additionally, since 2003, we have been measuring groundwater at the site boundary once a year, and we continue to confirm that there are no problems with groundwater.

Initiatives to control chemical substance emissions

Among the chemical substances emitted from Complex, the substances subject to the PRTR Act (Act on the Promotion of Ascertainment of the Amount of Specified Chemical Substances Released into the Environment and Promotion of Management Improvement) include benzene, which is contained in crude oil and petroleum products. In addition to toluene and xylene, there is asbestos, which was used as a pipe insulation material.

For target substances derived from crude oil and petroleum products (benzene, toluene, xylene), we have adopted floating roof tanks that emit less vapor from the tanks into the atmosphere, and installed volatile hydrocarbon recovery equipment at shipping facilities. We are working to suppress emissions.

Gas recovery at lorry station

Gas recovery equipment at lorry station

Since the beginning of operations, Complex has installed a volatile organic compounds (VOC) recovery device at the lorry station to recover hydrocarbon gas generated when loading tank trucks. The recovery method is to absorb hydrocarbon gases by bringing them into contact with kerosene, which is recovered oil, within the equipment, thereby reducing emissions into the atmosphere.

environmental data

Corporate forest

In 2010, our Complex was certified as a "Social and Environmental Contribution Green Space" under the "Social and Environmental Contribution Green Space Evaluation System" (SEGES) operated by the Urban Greenery Foundation (currently the Urban Greenery Agency).

This is in recognition of our activities to create the "Park Factory" that we have been aiming for since the construction of Tokuyama Refinery and the "Idemitsu 100 Year Forest" for Idemitsu's 100th anniversary of operation, and Aichi Complex was certified as "Excellent Stage 3".

In addition, based on the Green Garden City concept of the [Chita Citizens' Pledge], coastal companies in Chita City are working together and in collaboration to maintain and improve the Green Belt, with the aim of contributing to biodiversity and ecosystem connections under the "Green Belt is an important local environment Resources". This certification is in recognition of the fact that our Complex is positioned at the center of these activities.

In 2016, the company was awarded the SEGES Superlative Stage, the highest level of SEGES certification, in recognition of its past activities.

Our Complex will continue its green space activities that contribute to the local environment.

Complex full of greenery

Take a walk on the promenade

Commuting road cleaning

The Chita Sanshi-kai, of which Aichi Complex is a member, conducts simultaneous cleaning of the famous port service roads twice a year. We recruit volunteers from among our staff and collect trash that has been thrown away along the median strip and side gutters.

Carefully pick up trash inside the median fence

Now let's start picking up trash!