Aichi Complex | Quality Initiatives

Since our Complex began operations, we have consistently promoted quality control activities based on the management philosophy of "consumer-oriented."

We became a JIS mark certified factory in 1977, and obtained certification under the new JIS mark display system in June 2007. We have also obtained ISO certification, an international standard for quality assurance, and strive to stably supply products that meet customer needs.

Obtained certification under the new JIS mark display system

The "New JIS Mark Display System" was introduced on October 1, 2005, following the revision of the Industrial Standardization Act on June 9, 2004. This system indicates compliance with the Japanese Industrial Standard (JIS), and by obtaining certification, the JIS mark can be displayed on products or packaging.

In June 2007, our Complex received certification under the "New JIS Mark Display System," which is proof of safety and reliability for our products. There are six types of certified products: high-octane gasoline, regular gasoline, kerosene, light oil, A heavy oil, and C heavy oil.

Acquired ISO9001 certification

Our Complex acquired the international quality standard ISO9002:1994 in 1996. Due to the standard revision in December 2000, we transitioned to the 2000 version in 2003, the 2008 version in 2009, and the 2015 version in 2018, and are currently ISO9001:2015. We carry out quality assurance activities based on a quality management system.

By introducing this quality management system, we strive for continuous improvement to ensure a stable supply of products that satisfy our customers.

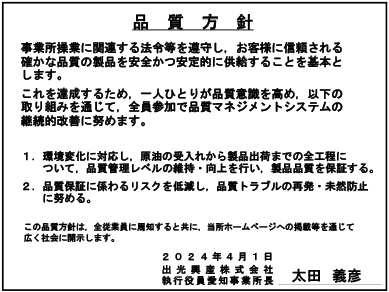

quality policy

quality policy

Manufacturing and shipping of environmentally friendly petroleum products

Since 1993, our four Refinery in Japan, including this Complex, have been producing low-benzene gasoline, "Idemitsu Super ZEARTH'' and "Idemitsu ZEARTH'', which contain benzene less than 1%. This was commercialized in advance of the benzene concentration regulations in 2000.

In addition, in advance of the sulfur-free movement to reduce the sulfur content to 10 ppm* or less, Complex installed a desulfurization equipment to remove sulfur from petroleum products, and in January 2005, we made gasoline and diesel oil sulfur-free. We have achieved this goal.

*10ppm=0.001%

In Japan, the law stipulated that diesel oil be made sulfur-free in 2007 and gasoline in 2008, but oil refining and wholesale companies that are members of the Japan Petroleum Federation, including our company, have made both sulfur-free gasoline and diesel oil sulfur-free in January 2005. We are the first in the world to begin shipping this month.

Movements to reduce sulfur content are progressing around the world, and in 2009 the EU also decided to make gasoline and diesel oil sulfur-free with a sulfur content of 10 ppm or less.

Sulfur-free gasoline production equipment

Sulfur-free gasoline production equipment

The cracked gasoline desulfurization equipment that produces sulfur-free gasoline is a device that significantly removes the sulfur content contained in the cracked gasoline refined by the heavy oil cracking equipment.

Sulfur-free diesel oil production equipment

Sulfur-free diesel oil production equipment

The diesel oil deep desulfurization equipment that produces sulfur-free diesel oil is a device that removes the sulfur content contained in diesel oil.