SAFの

供給体制を構築し

脱炭素社会の

実現につなげる。

-

Carbon Neutral Transformation Department

Carbon Neutral Transformation Department

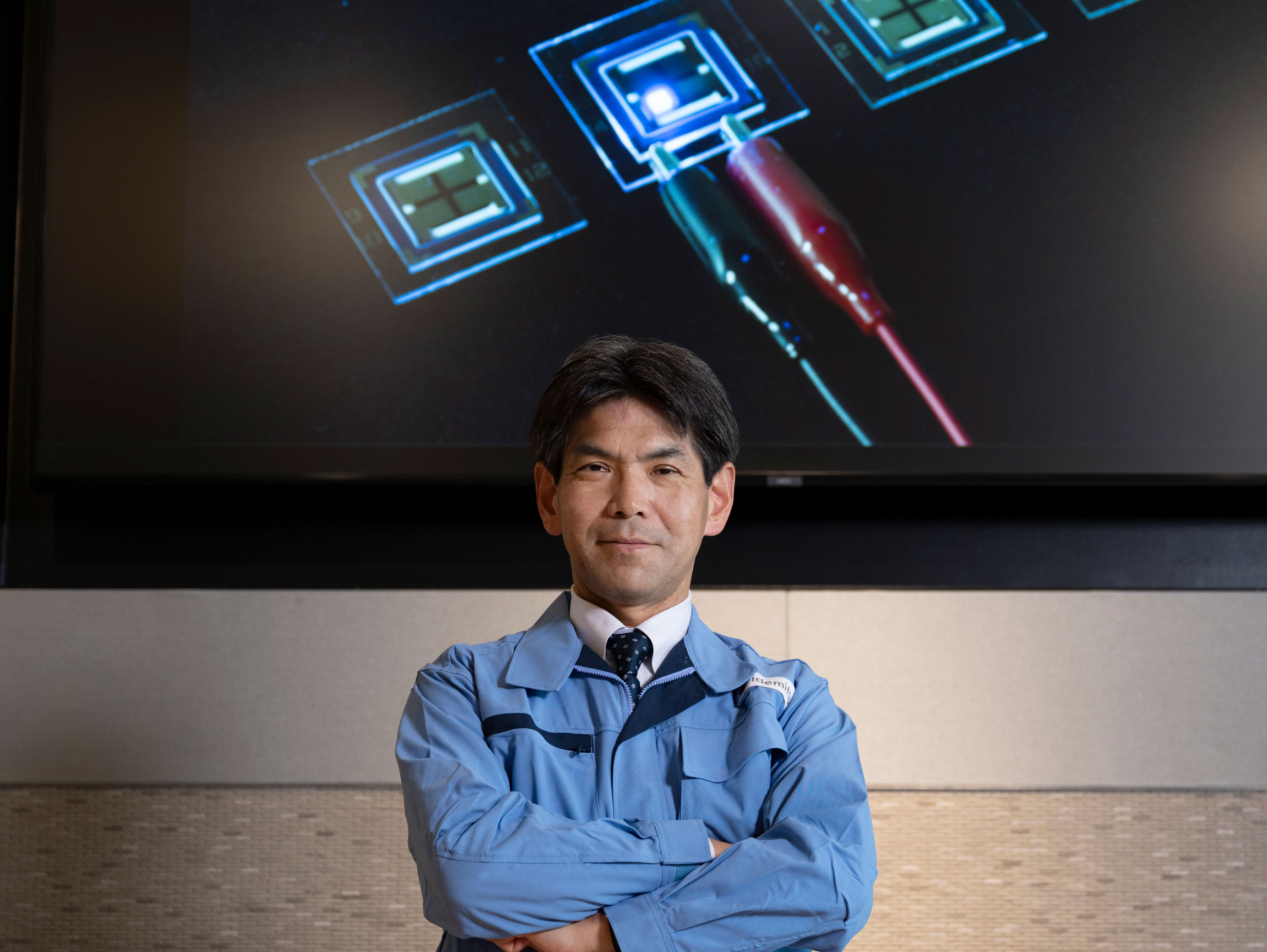

Biomass and Synthetic Fuel Business Promotion SectionK.TOYOTSU

As we grapple with the 2050 problem on a global scale, achieving carbon neutrality is a must-achieve goal. Idemitsu Kosan is working to supply "SAF (sustainable aviation fuel)" *1 domestically.

Leveraging the knowledge, human resources, and assets of the existing oil and petrochemical businesses, the company aims to supply 500,000 kL/year domestically by 2030. We interviewed a business development manager working to build a stable supply system in the new field of SAF, focusing on the theme of "connecting."

- 1. Abbreviation for Sustainable Aviation Fuel.

Joined the company in 2006 and assigned to Showa Yokkaichi Sekiyu Co., Ltd. Yokkaichi Refinery. Transferred to Manufacturing & Technology Department in 2012, responsible for budget management of group Refinery, formulation of mid-term capital investment plans, promotion of energy conservation, collaboration with other companies, etc. Seconded to Shell Global Solutions (Netherlands) in 2020, engaged in providing technical services to customers as a process engineer. Returned to Manufacturing & Technology Department in 2022. Transferred to Carbon Neutral Transformation Department in 2023. Mainly responsible for building and promoting the SAF business, represented by the Tokuyama HEFA-SAF project and the Chiba ATJ-SAF project.

多様な経験と視点を

掛け合わせ、

プロジェクトの

推進力を加速させる。

Working across departments to achieve carbon neutrality

Following the international aviation organization's goal of achieving "net zero CO2 emissions by 2050," Japan aims to replace part of the jet fuel used by domestic airlines with SAF by 2030.

Idemitsu Kosan is currently working to build a domestic supply system for SAF, centered on two projects: HEFA *2-SAF production at Tokuyama Complex and ATJ *3-SAF production at Chiba Complex. The CNX *4 Strategy Headquarters is a cross-departmental organization established to promote provide for society of "Energy one step ahead" that is essential to achieving carbon neutrality, such as SAF, hydrogen, ammonia, and synthetic fuel.

"My areas of responsibility include setting the basic concepts and evaluation criteria that will be shared in advancing the SAF manufacturing project, formulating guidelines for utilizing government support systems for large investments, and leading the company's consensus-building and decision-making processes. By involving multiple business departments, we can utilize each other's resources and share knowledge to increase the momentum of each project. With participation from other departments, we have a system that can be considered a strategic headquarters that promotes cooperation between various departments within the company."

A one-minute guide to "The Future Sky Created by SAF"

- 2. HEFA (Hydroprocessed Esters and Fatty Acids) is a technology that produces SAF by hydrotreating used edible oil and other fats and oils.

- 3. ATJ (Alcohol to Jet) is a technology to produce SAF from ethanol and other fuels.

- 4. Abbreviation for Carbon Neutral Transformation.

Utilizing your work experience to advance projects

"When I joined the company, I worked Refinery. At manufacturing sites, safety and a stable supply are our number one priority when operating equipment and manufacturing products. At Carbon Neutral Transformation Department where I currently work, each department within the company is working on projects with their own roles and responsibilities, from sourcing raw materials for 'Energy one step ahead' to manufacturing and sales. I myself sometimes speak with internal departments that design equipment, and sometimes with external parties that supply products. In order to realize a decarbonized society, I am required to understand everything from customer needs to the status of facility design considerations, and to show the best way to proceed with projects and the best direction for both the customer and our company."

After working in Refinery and Manufacturing & Technology Department, he was seconded to the Shell Group's technical center in the Netherlands in 2020. While working as a process engineer, he witnessed the progress of the world's leading SAF project in Europe and the United States. At that time in Japan, it was still in the research stage and no concrete movement was seen.

"At our company, this was before the in-house project was even launched, so it felt like Europe was ahead of us in terms of timeline. At the same time, I had a premonition that the time would come when we would have to do it in Japan as well."

脱炭素社会への

ロードマップを描き

2030年と

その先を目指す。

What is the significance of Idemitsu Kosan's SAF project?

"In the larger context of society, we must reduce CO₂ emissions. At the same time, social development is also essential. Next-generation energy sources such as SAF and synthetic fuel that can achieve both are attracting attention, and we are confident that because we have supplied large amounts of energy, we can put these technologies into practical provide for society."

SAF projects are expected to be the closest to social implementation.

"We are conducting our business with the determination to lead the way in realizing carbon neutrality society. As a part of the social infrastructure that supplies the fuels and materials necessary for daily life, we must provide the world with products and services that reduce the environmental burden. I believe that we need to respond to the needs of society and change ourselves to meet those needs."

Strengths that can be utilized to achieve carbon neutrality

"Our goal is to achieve carbon neutrality for emissions from our own operations by 2050. In addition, we will contribute to achieving carbon neutrality for the world as a whole by providing decarbonization products and schemes. One milestone on that path is to achieve our goal of 'establishing a domestic SAF supply system with an annual capacity of 500,000 kL by 2030,' and we are working to promote the SAF project as an important measure."

Idemitsu Kosan, which has long supported energy infrastructure in Japan, is seen as one of the companies leading the domestic SAF manufacturing and supply business.

"Our company already has a supply network for the production, transportation, and sales of jet fuel. Although SAF needs to build new raw material procurement and manufacturing operations, a major advantage is that it can utilize existing networks for transportation and sales supply chains. In addition, neat SAF *5 cannot be made into a product on its own; it needs to be mixed with fossil-derived jet fuel to turn it into product SAF. We believe that our knowledge as a manufacturer and seller of fossil-derived jet fuel will also be able to be utilized in the quality control and quality assurance of product SAF."

- 5. Jet fuel produced from biomass feedstocks, etc.

The challenge of introducing new energy sources

There are significant differences between the raw materials and manufacturing processes used for SAF and those used with conventional fossil fuels. What kind of difficulties and new challenges does this pose?

"The main flow of the oil refining process is to procure crude oil produced in the Middle East and elsewhere, refine it, and turn it into a product. However, with SAF, we must always consider reducing the environmental impact. The raw materials are recycled from materials that would previously have been discarded, such as used cooking oil and animal fats. Not only that, but CO2 emissions are counted throughout the entire flow, from the process leading up to the completion of the raw materials, transportation to Refineries/Complexes, the manufacturing process, and delivery to the customer. We need to consider not only costs but also the energy input."

How does it feel for you personally to be involved in a project that addresses a global issue?

"Having a clear understanding of how your work is useful allows you to work proactively and makes your work more rewarding. Recently, SAF has been featured in general news, and I feel that there is a growing social need for it. The other day, my daughter, who is in elementary school, was answering a written question that described the transition to decarbonization and renewable energy. It made me realize that my work is related to global issues and is an initiative that will connect to the next generation."

ジェット燃料の

新時代に向けて

SAFの供給を

確かなものにする。

Realizing an SAF supply system with a wide range of options

"As the foundation for promoting the SAF manufacturing projects in Chiba and Tokuyama, we have the 'establishment of CNXcenter Initiative' to utilize our manufacturing facilities to transform them into carbon-free, low-carbon energy supply bases. Under this initiative, we are working in parallel to manufacture SAF using different raw materials and technologies at our separate facilities in Chiba and Tokuyama. At other facilities, we are also considering commercializing hydrogen, ammonia, synthetic fuel, and other products. I think that having a variety of options in anticipation of future needs in each region is one of our company's unique features. We will also likely establish a supply system for the necessary SAF in various forms, including investing in and offtake from overseas projects, not just domestically. We will explore how best to establish a supply system, not just domestically, but also including overseas projects as options. We need to consider the next measures comprehensively, including the perspective of environmental impact and cost. That's why I think there is still a long way to go."

With an eye on the future, we will "connect" each and every result

"My current job is creating the gateway for Idemitsu Kosan's SAF business into the future. As a path to that, we will first aim to establish a domestic supply system of 500,000 kL per year, which is our target for 2030. Then, using 2030 as a checkpoint, we will challenge ourselves to realize an SAF supply system for 2040 and for 2050, which will see us achieve carbon neutrality. Using the realization of these goals as precedents, I believe it is my mission to 'connect' Idemitsu Kosan's SAF business to the future."

Idemitsu Kosan's corporate culture, which no other company has,

was first noticed when I was transferred to a foreign country.

In 2020, Toyotsu was seconded to Shell Global Solution in the Netherlands. "Because it was a different company from Idemitsu Kosan, the atmosphere and culture of the workplace were completely different," he says, which allowed him to once again appreciate the good things about Idemitsu Kosan. "The way of working that is common in overseas companies is that each individual's role is clearly defined and they only work within their own scope. For me, it was natural to think of my colleagues' work as part of my own job and cooperate with them, rather than treating it as someone else's. Working together and cooperating with each other often leads to success, and I was reminded that this is one of the good things about our company."

*As of August 2024

Related interviews

-

百年以上もの歴史で

培われてきた

潤滑油の技術と心を

次世代へつなげる。2024.03.21 UPLubricants Department 2 Kanto Lubricants Section 2M.YAMADA -

石油製品を毎日

安定供給することで

人々の暮らしを守る。2024.03.21 UPChiba Complex Refinery Section 1M.YOSHIHARA -

有機ELの世界に

活路を見出した

先達の意思を継いで

未来を切り拓く。2024.04.30 UPAdvanced Materials Company Electronic Materials DepartmentM. FUNAHASHI