A one-minute guide to "The Future Sky Created by SAF"

In order to realize carbon neutrality society, the supply and practical application of new energy sources is being challenged. In the aviation sector, the International Civil Aviation Organization (ICAO) has set greenhouse gas reduction targets, and Japan is also included in these targets. Yes, the supply and practical application of SAF (sustainable aviation fuel) is now in a state where no time can be wasted.

To achieve this goal, we at Idemitsu plan to establish an SAF supply system with a capacity of 500,000 kL per year by 2030.

Q1. Why is SAF attracting attention?

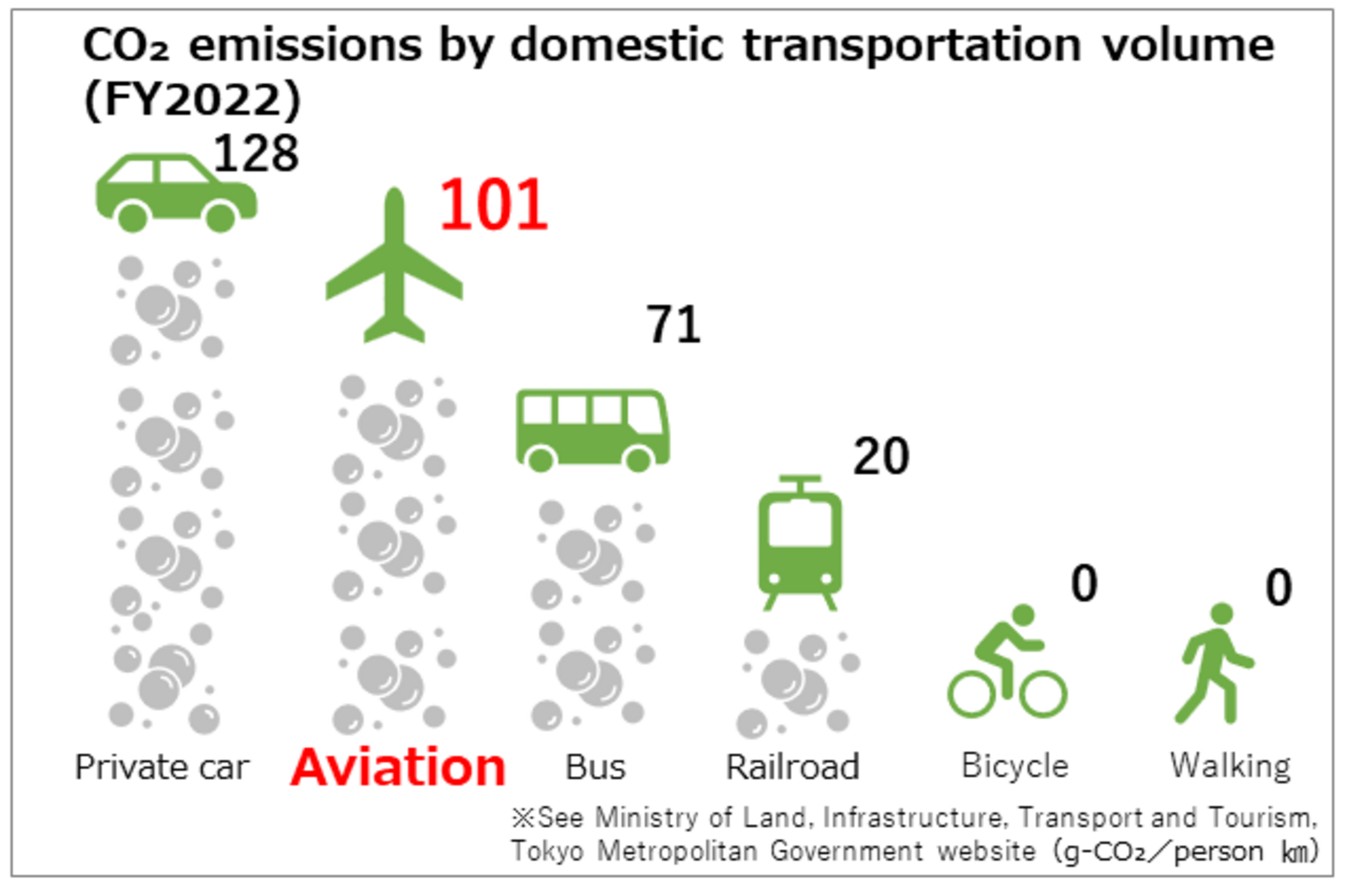

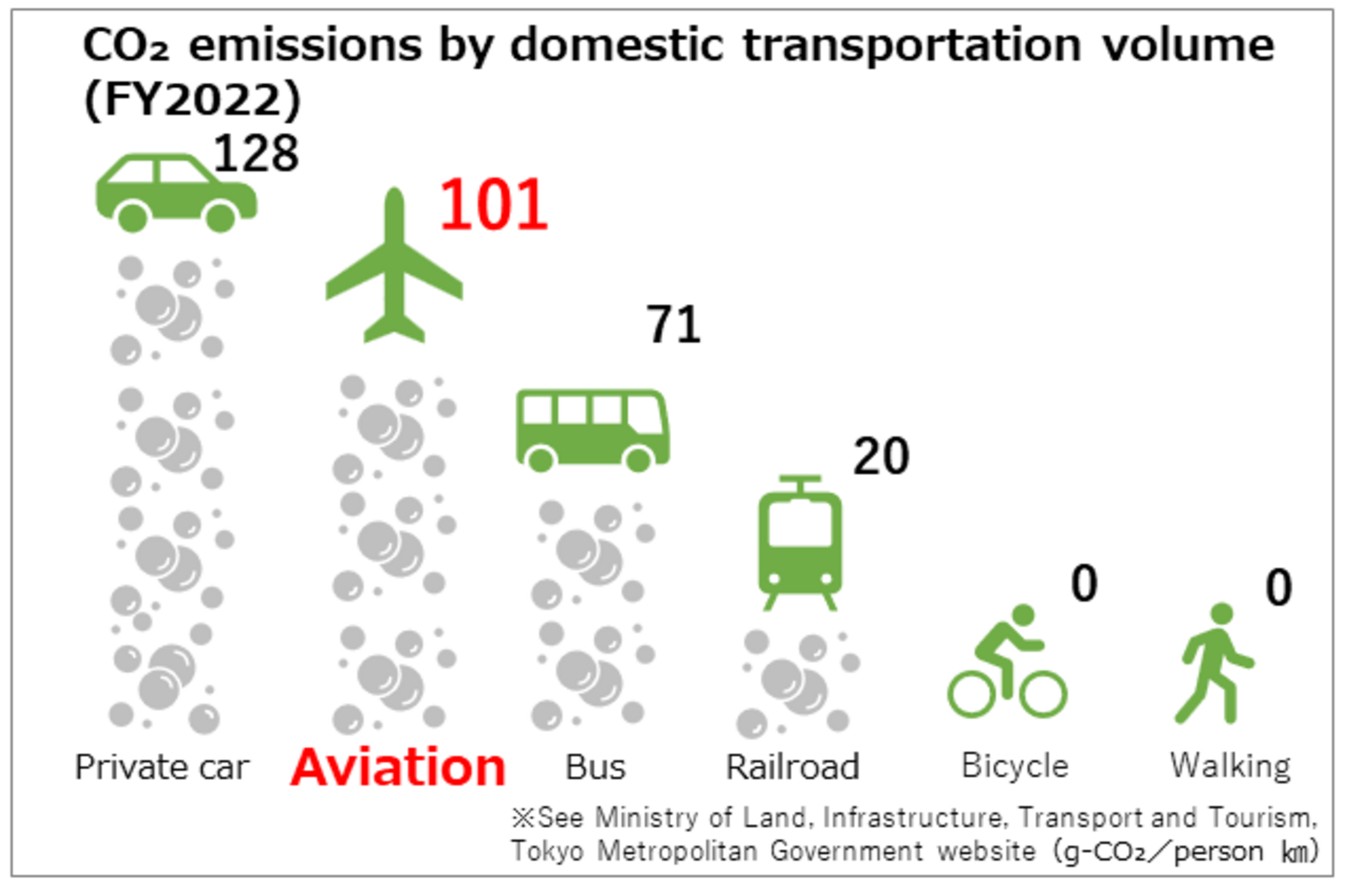

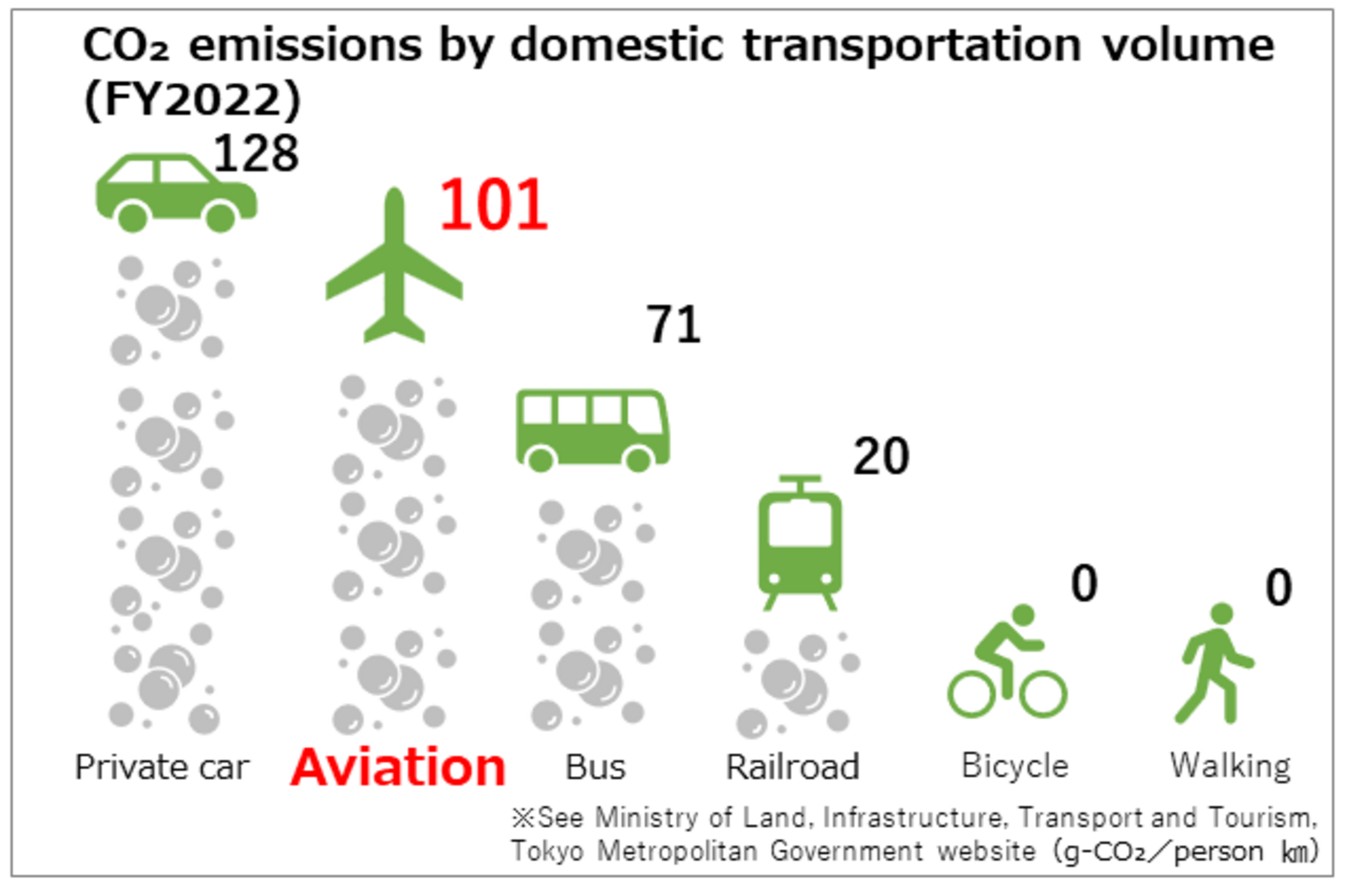

A. In the transportation sector, aircraft are the second largest emitter of CO₂ after automobiles, and therefore have a large impact on achieving carbon neutrality.

It has been reported that in Japan, airplanes are the second largest source of CO₂ emissions per unit of transportation after private cars. While the automotive industry is progressing with the development of electric vehicles, the aviation industry is also working to reduce CO₂ emissions, with the international organization ICAO setting a goal of "not increasing total CO₂ emissions after 2020."

Q2. What are the key points in reducing CO₂ emissions from aviation?

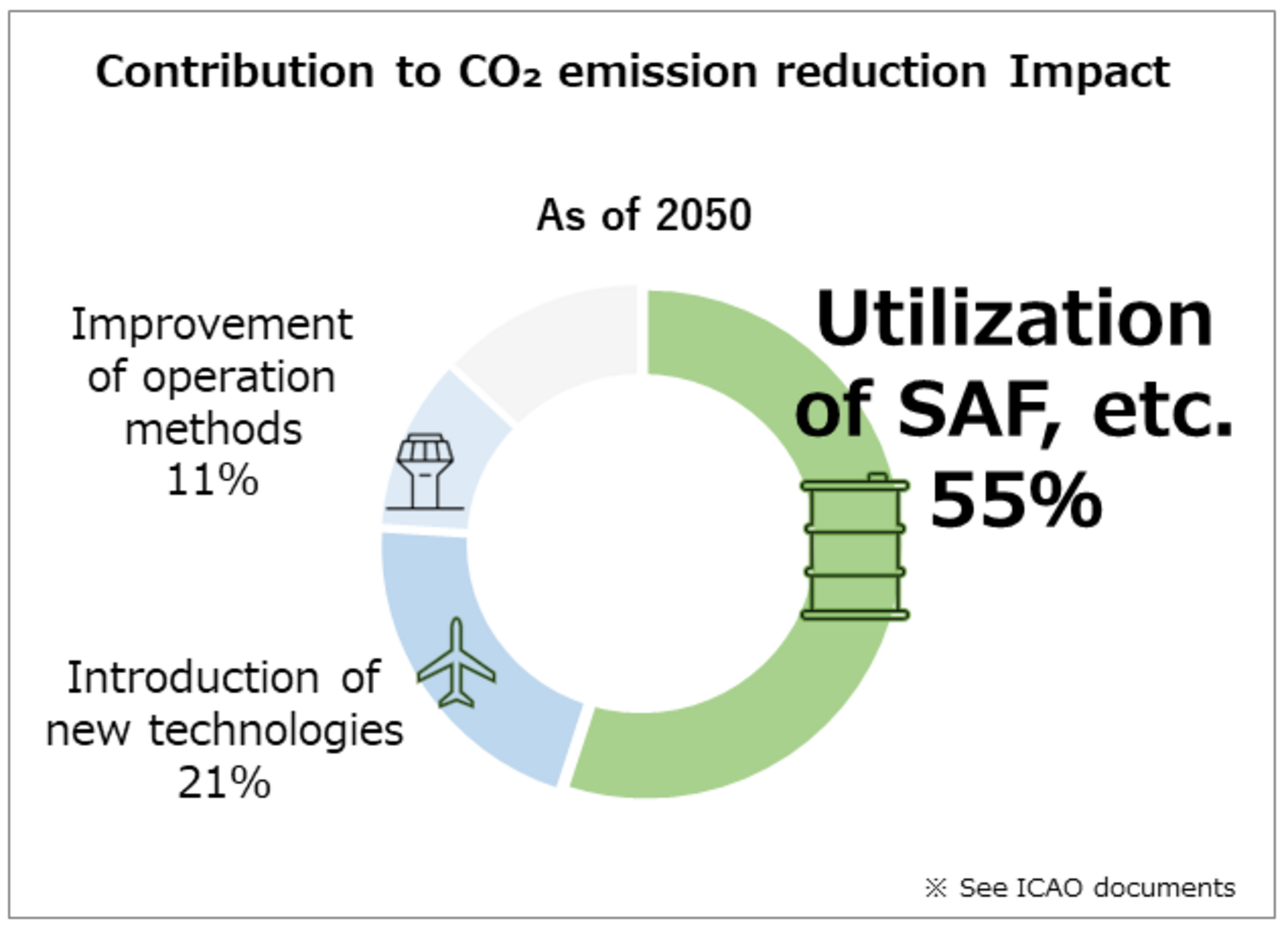

A. The most important thing is the SAF. In addition to using the SAF, we aim to achieve our goals by combining various methods.

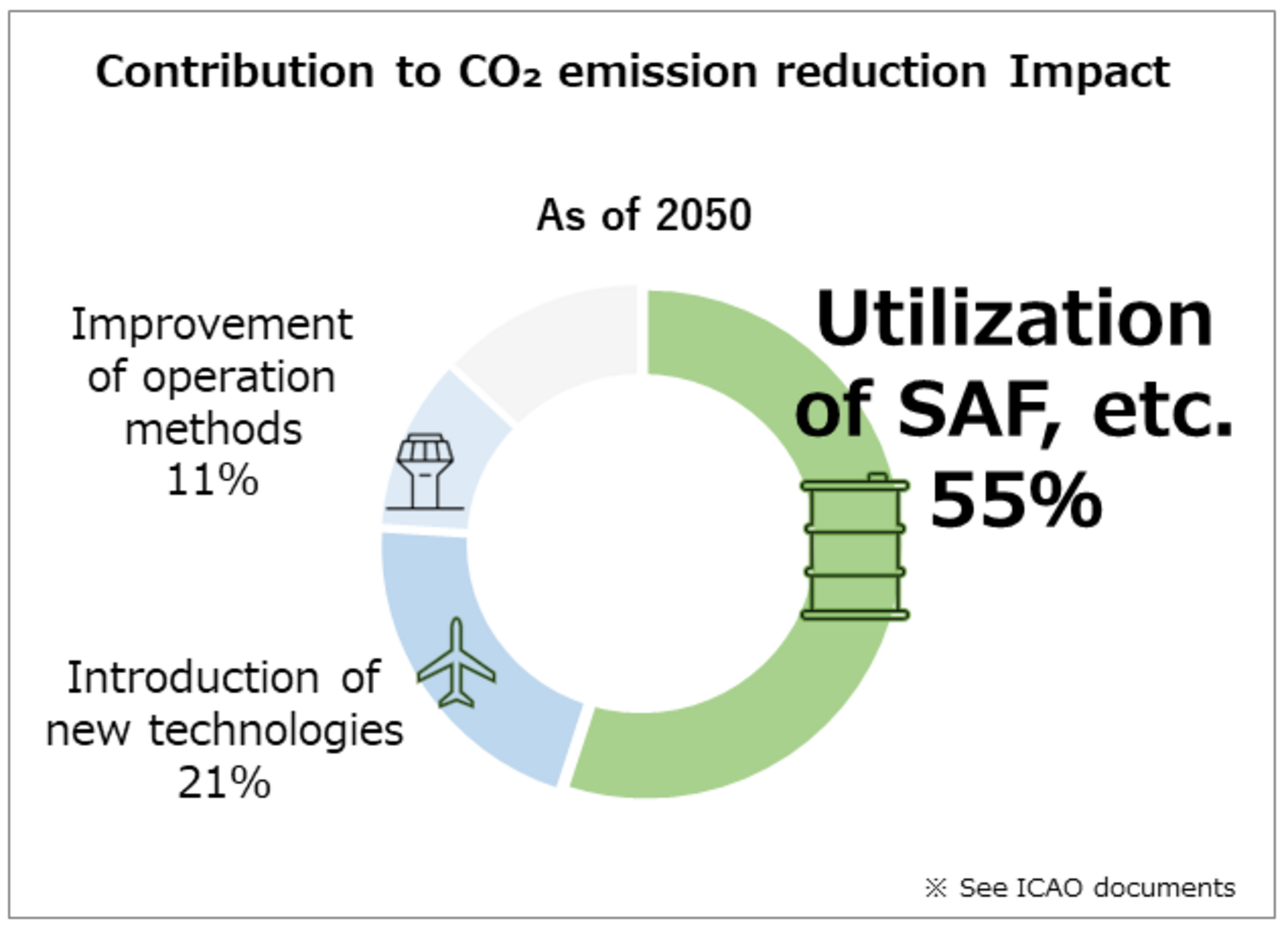

As can be seen in the diagram below, it is expected that these goals will be achieved through a combination of "new technology," "improved operational procedures," and "SAF."

The introduction of "new technologies" such as electrification and hydrogen aircraft is also being considered, but these are expected to be small aircraft or short-distance aircraft. In addition, "improvements to flight operations" such as optimizing air traffic overall are also being considered. However, for the time being, it is believed that the greatest impact will be on reducing CO₂ emissions through the use of "SAF," and it is no exaggeration to say that the supply of SAF will create the skies of the future.

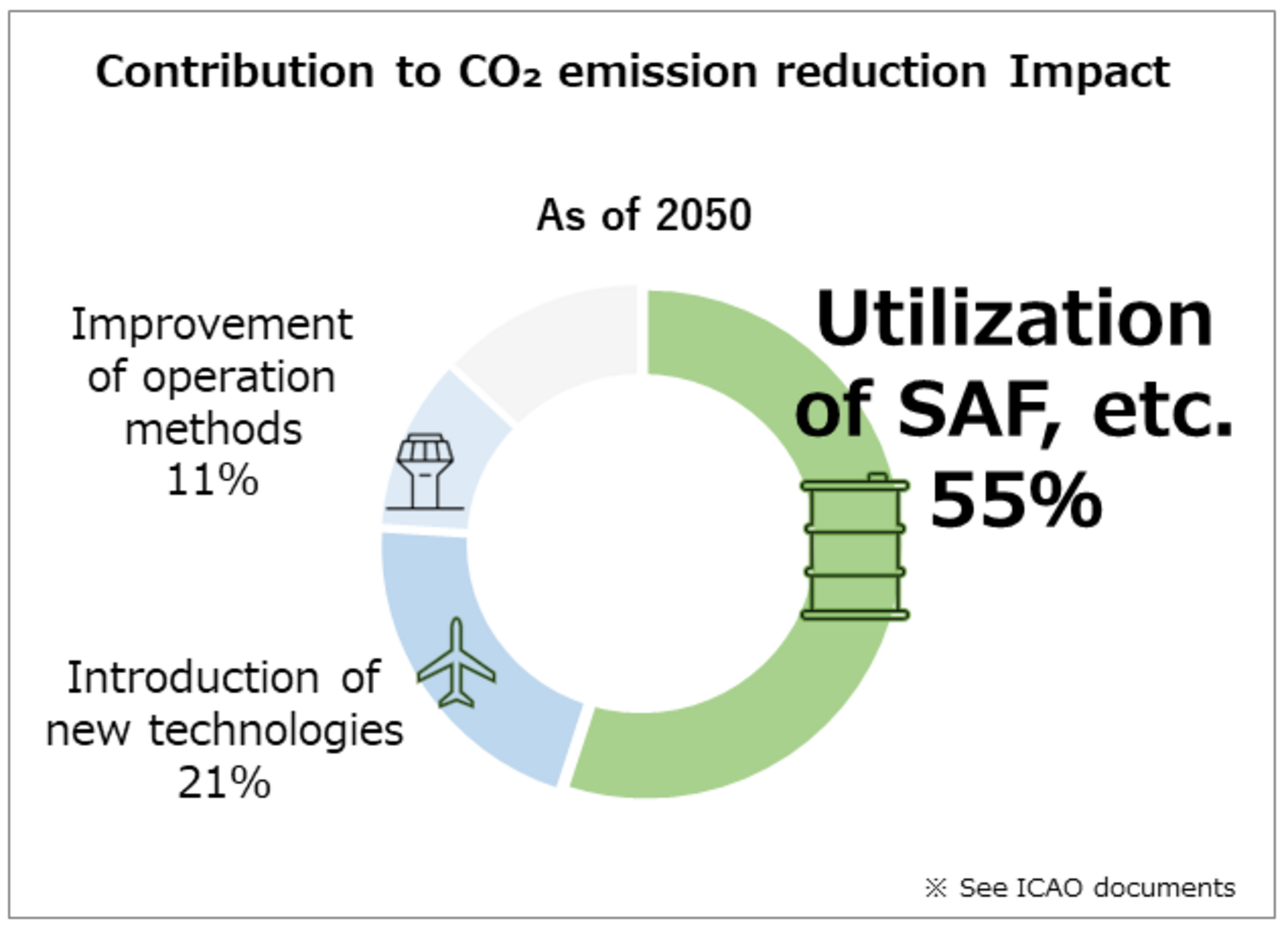

Global passenger traffic is expected to continue to increase in the future

Global passenger traffic is expected to continue to grow and will be more than double the current number by 2050. This will require not only improving aircraft fuel efficiency, but also ensuring and improving quality, such as ensuring a stable supply of SAF and raising the upper limit on the amount of SAF that can be mixed with conventional fuel. Idemitsu's challenge to supply SAF continues.

Q3. What is SAF made from?

A. There are eight different manufacturing standards, and they are derived from oils, fats, biomass, etc.

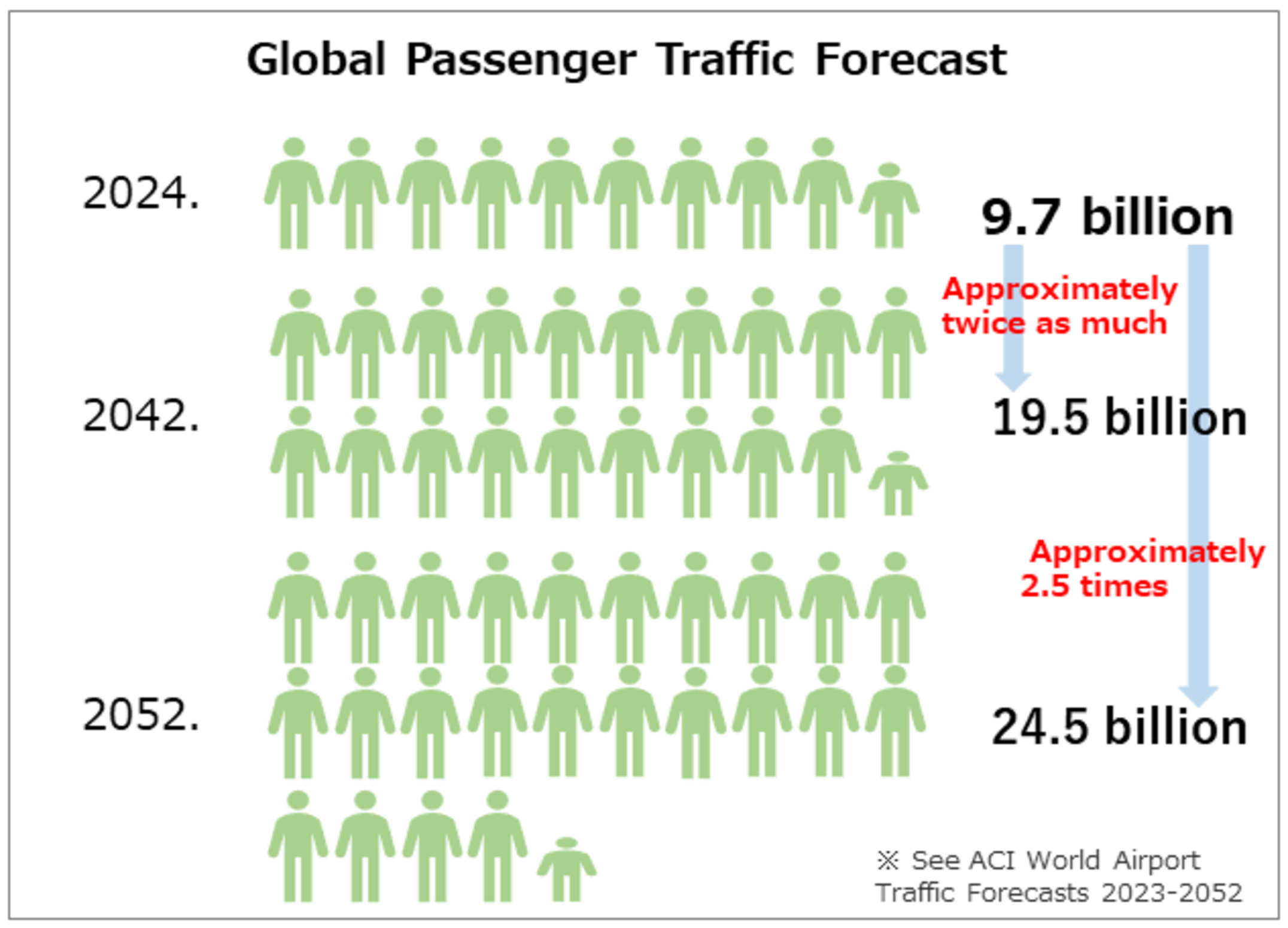

While conventional aviation fuel is made from crude oil, SAF can be made from a variety of feedstocks and through different production methods. Eight different production standards have been approved by the international standards-setting body (ASTM International) (as of July 2024), and the blending ratio with conventional aviation fuel is also limited.

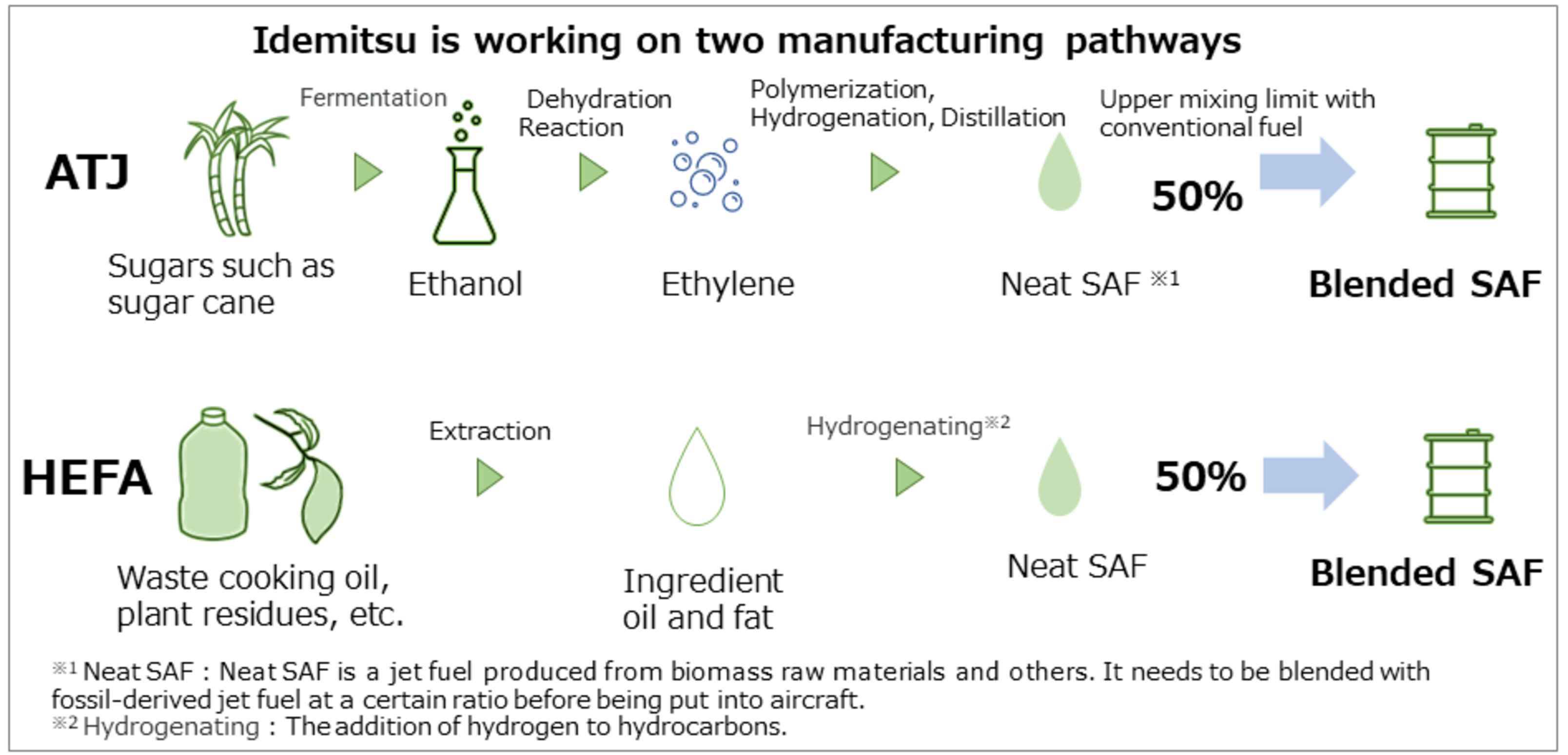

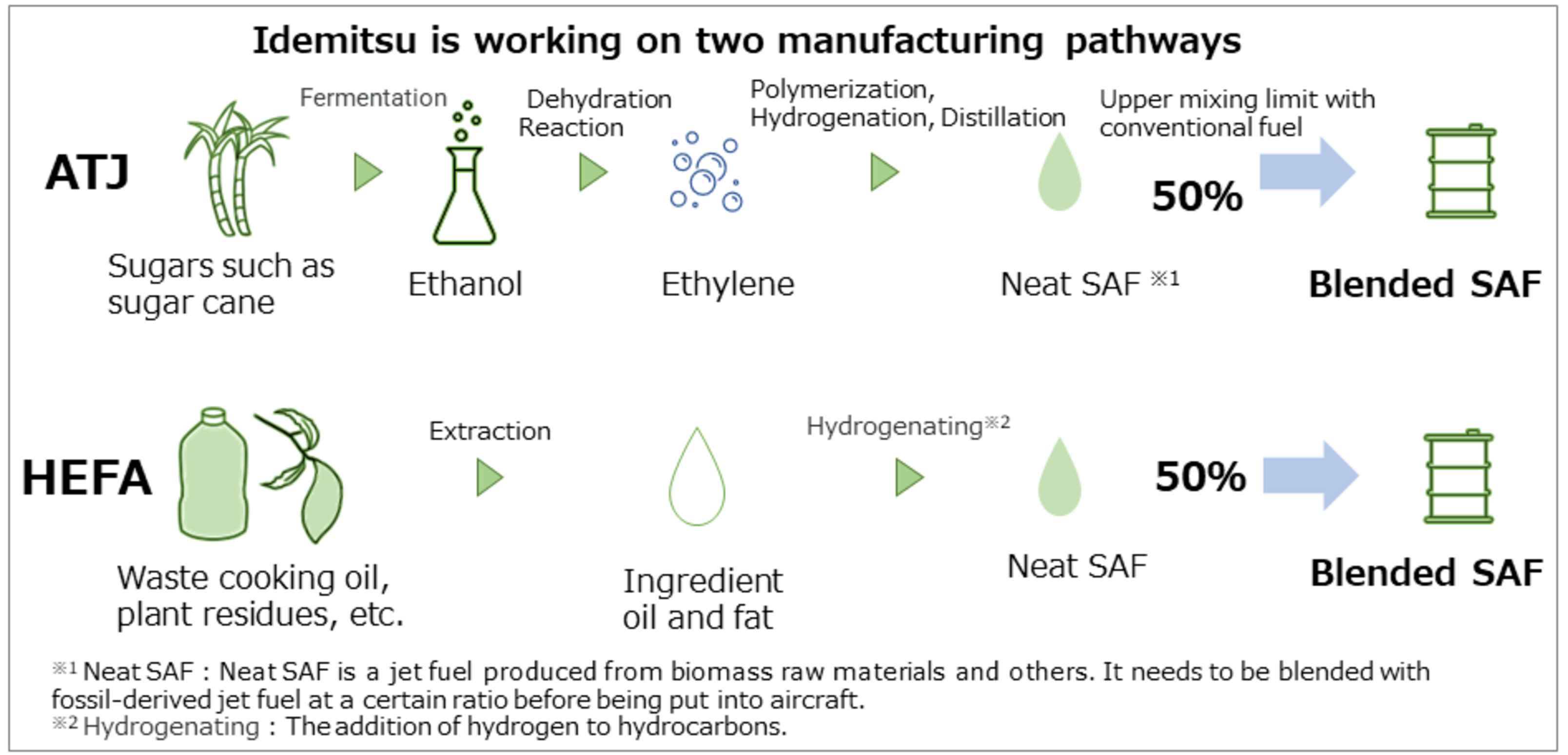

Idemitsu is working on two of these manufacturing methods: "ATJ" and "HEFA".

-

ATJ (ATJ: Alcohol to Jet, a technology for producing SAF from ethanol, etc.)

-

HEFA (Abbreviation for Hydroprocessed Esters and Fatty Acids. Technology for producing SAF by hydrotreating used cooking oil and other fats and oils)

Q4. Why can SAF be considered an environmentally friendly energy source?

A. Because it allows us to keep CO₂ in circulation and reuse waste materials.

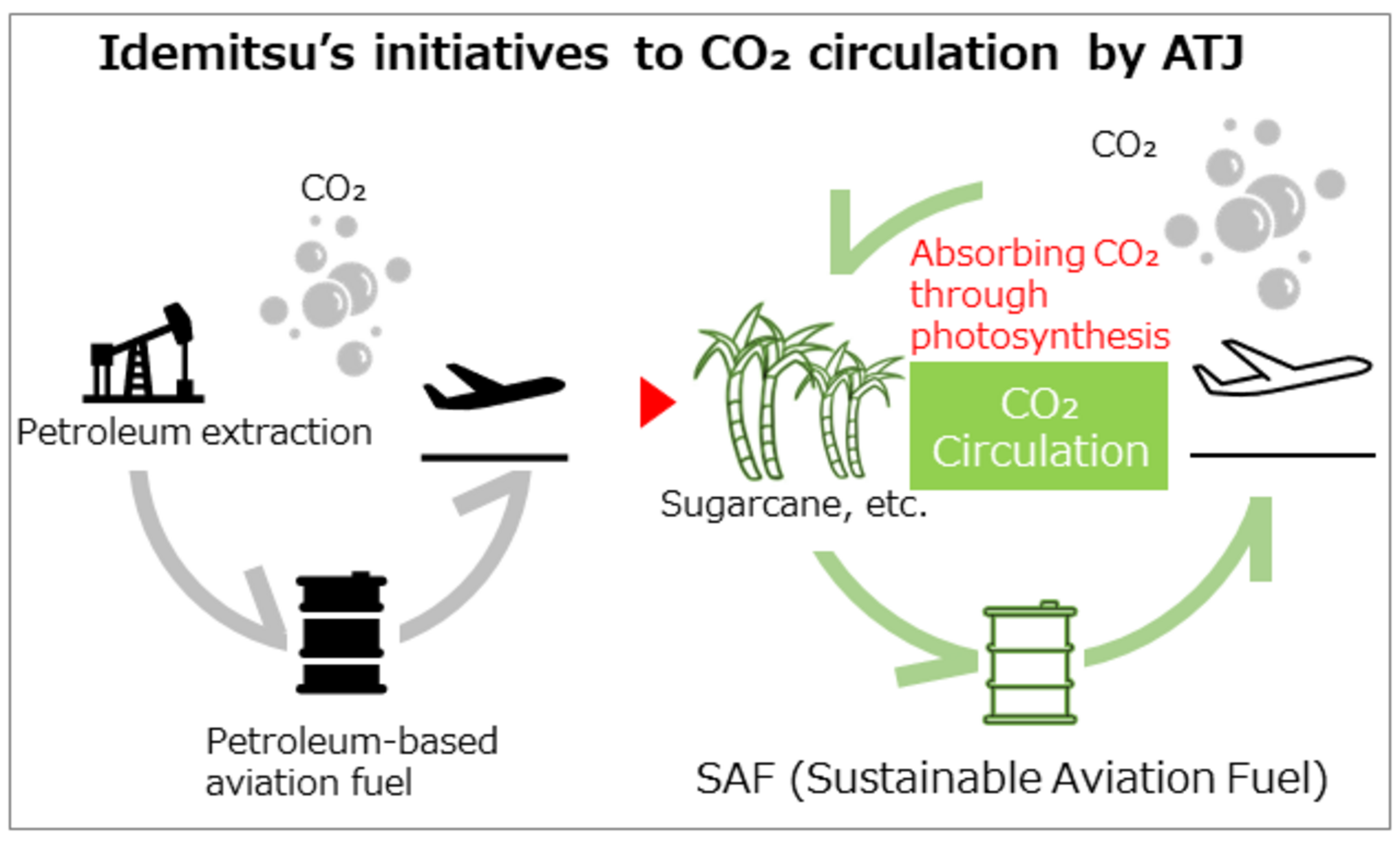

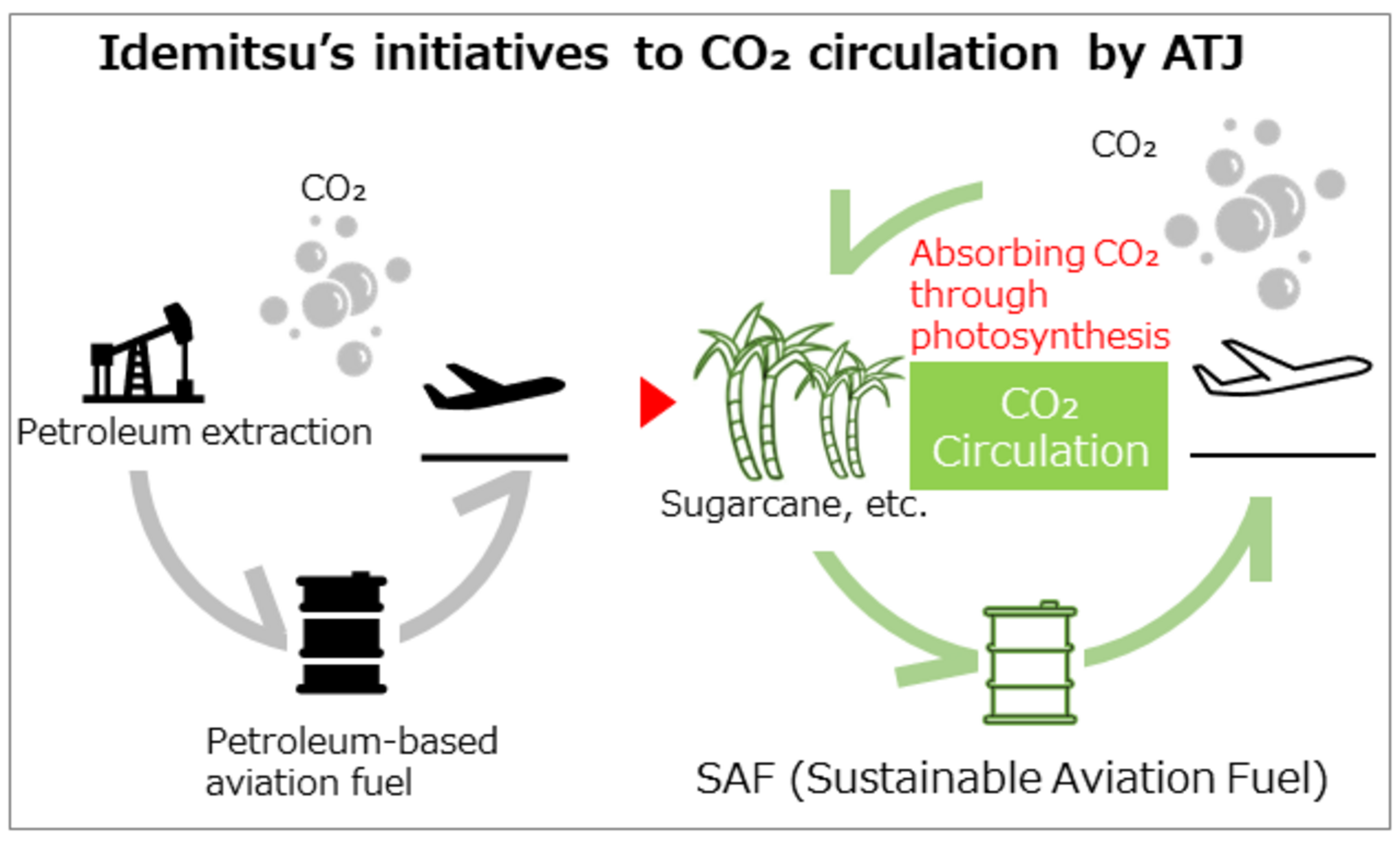

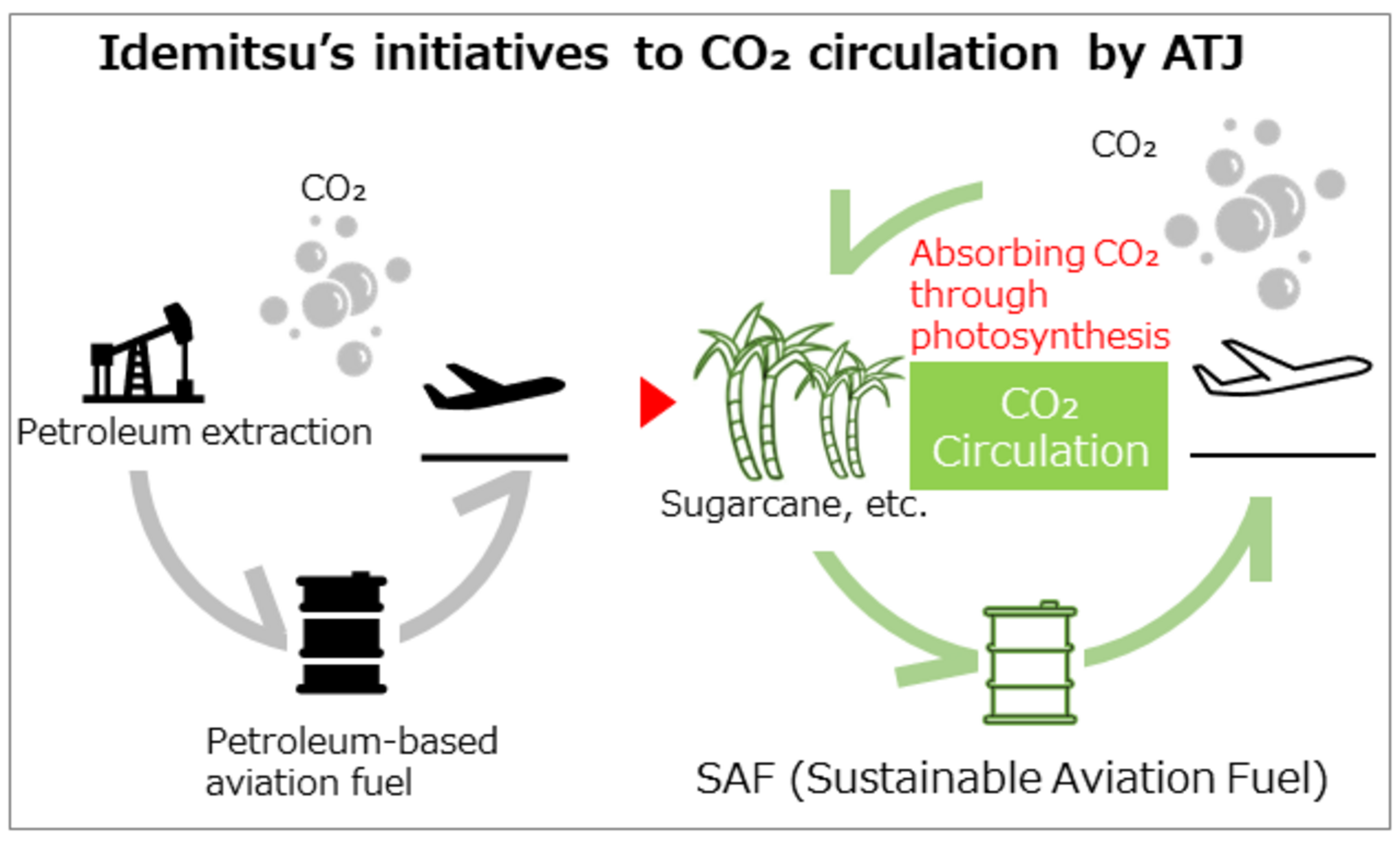

For example, Idemitsu's "ATJ" is made from sugarcane. During the growing process, sugarcane absorbs CO₂ from the atmosphere through photosynthesis. Therefore, even if sugarcane emits CO₂ when used as fuel, the CO2 that was previously absorbed can be deducted.

By making good use of the natural CO₂ cycle, we can meet our air transportation needs with almost no increase in CO₂ in the atmosphere compared to using conventional aviation fuel.

Other manufacturing methods involve reusing raw materials that would otherwise be discarded.

Q5. Why does Idemitsu work on two different manufacturing methods?

A. To fulfill our responsibility to provide a stable supply of SAF into the future

In terms of establishing large-scale manufacturing technology, "HEFA" is ahead of the rest of the world. However, the oils and fats that are the raw materials for "HEFA" are in limited supply, and prices can fluctuate significantly.

Idemitsu believes that in order to fulfill its responsibility to supply SAF into the future, it is necessary to put into practical use multiple raw materials and manufacturing technologies. Large-scale production of "ATJ" has not been demonstrated anywhere in the world, but Idemitsu will be the first to attempt this. In addition, in order to secure raw materials for "HEFA", we are also considering cultivating and using oil plants such as pongamia as raw materials.

Idemitsu's Goals and Actions for 2050

We introduce Idemitsu's challenges in the area of Energy one step ahead such as SAF, synthetic fuel, ammonia, and hydrogen.