Chiba Complex | Safety Initiatives

At our company, we prioritize environmental conservation and safety measures over our production activities. At our Chiba Complex, we are working to prevent problems from occurring, based on the basic policy of "safety first."

Additionally, in case of fire or oil leaks, we have disaster prevention equipment and have organized a self-defense disaster prevention team to conduct thorough disaster prevention drills on a regular basis.

Occupational safety and health policy

Chiba Complex

Security management policy

Chiba Complex

High pressure gas specific certified business operator

Chiba Complex was certified as a specific certified business (commonly known as a super certified Complex) under the specific certified business system established by the Ministry of Economy, Trade and Industry on March 17, 2020, becoming the first such business in Chiba Prefecture (its certification has been renewed continuously since August 2000).

We are proud of this certification and will continue to work to further improve our independent safety measures, thereby working to ensure safe operations and a stable supply of energy.

Strengthening security capabilities through third parties

In June 2018, Chiba Complex underwent a "security capability (safety foundation and safety culture) evaluation" by the Non-Profit Organization Safety Competency Improvement Center. As a result, we received high evaluations on many indicators, including our existing "Risk Assessment (RA)'' and "Education System for Company-wide Human Resource Development.'' On the other hand, in the evaluation of "safety infrastructure and safety culture," opportunities for improvement were found in several indicators. We receive advice in areas such as safety management and are working on improvements with the aim of further raising the level of safety.

Disaster prevention equipment

| Disaster prevention equipment | Number owned/installed | ||

|---|---|---|---|

| fire engine | Chiba Complex |

Large chemical aerial water cannon vehicles: 3 units Large chemical fire engines: 2 units Ordinary foam water cannon: 1 unit Raw solution transport vehicle: 3 units |

|

| fire pump | Chiba Complex |

1,700t/h: 3 units 1,000t/h: 2 units 600t/h: 2 units 550t/h: 1 unit 500t/h: 1 unit 400t/h: 1 unit 200t/h: 1 unit |

|

| outdoor fire hydrant | Chiba Complex | 1,075 units | |

| Fixed foam fire extinguishing equipment | Chiba Complex |

Yard area fixed foam fire extinguishing equipment: 54 units Foam fire extinguishing equipment for tanks: 5 units |

|

| Fixed watering equipment | All equipment that handles hazardous materials and high pressure gas | ||

| oil fence | Fixed floating type | Around the anchored ship | 1,940m |

| portable | Chiba Complex | 2,032m | |

| Disaster prevention command vehicle | Two | ||

| work boat | 3 ships | ||

fire engine

Disaster prevention command vehicle

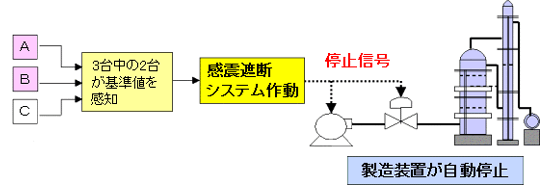

Automatic equipment shutdown system in the event of an earthquake

In the event of an earthquake at Complex, if two of the three seismic sensors installed in the operations department detect the standard value, the seismic isolation system will be activated and the manufacturing equipment will automatically stop.

The standard value is 150 gal for refining/manufacturing areas and 200 gal for utility (in-house power generation/boiler) supply areas.

Site overview

flare stack

flare stack

Flare stacks are equipment used to burn and safely discharge excess fuel gas and flammable gas that are generated when starting and stopping oil refineries and petrochemical manufacturing equipment, and when making operational adjustments. Our Complex handles large amounts of hazardous materials and high-pressure gases. If excess flammable gas is released directly into the atmosphere, it could cause fires, explosions, and environmental pollution. Flare stacks are an important safety feature for facilities.

In the past, a bright red flame was the symbol of Refinery, but in recent years, the gas that was discharged into the flare stack is now recovered and put to effective use as fuel gas.

It suppresses CO2 emissions and contributes to the prevention of global warming.