Technical services and consulting

Coal & Environment Research Laboratory

Coal plays an important role as one of the major primary energies. On the other hand, CO2 is generated with use, so efforts are required to reduce emissions.

Coal & Environment Research Laboratory is Japan's only comprehensive research institute specializing in coal, working to realize environmentally harmonious coal operations and address various technical challenges faced by our customers.

For customers who use coal, we back up the entire supply chain and provide proposals for optimal coal combustion using clean coal technology. We are also actively promoting the reduction of CO2 emissions through biomass co-firing and the development of technology to use CO2 as a chemical raw material.

technology consulting

Based on the high-efficiency coal combustion technology and environmental protection technology that we have cultivated over many years, we develop technologies and systems that contribute to solving customers' technical issues and environmental issues, and use these tools to meet the diverse needs of customers.

Combustion simulation (boiler combustion optimization)

We use a computer to analyze gas flow, temperature distribution, and particle trajectories within the furnace and propose optimal boiler operating conditions.

Features

Features

Idemitsu has developed a pulverized coal combustion simulator to analyze gas flow, particle trajectories, temperature distribution, etc. inside the boiler. This has great power in selecting the optimal coal based on the characteristics of the equipment, and in considering the optimization of operating conditions, such as improving combustion efficiency (reducing unburned carbon), reducing NOx, and reducing ash adhesion (slagging).

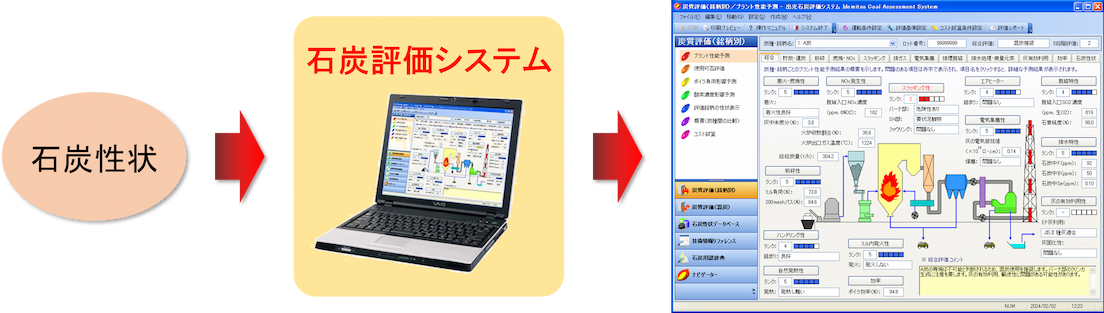

coal evaluation system

The "Idemitsu Coal Evaluation System" brings together the coal quality evaluation technology that our company has cultivated over many years.

This system, which accurately predicts the performance of new coal and supports the expansion of coal types used in coal boilers, has been adopted by many pulverized coal-fired power plants and factories.

Features

Features

-

Quick and accurate judgment on whether new coal types can be used

-

Shortening the combustion test (trial) period and reducing costs

-

Predicting trouble and considering countermeasures

-

Avoid trouble before it happens

-

Examination of optimal coal blend conditions

-

Abundant technical information (coal quality evaluation technology, trouble cases, mine information, etc.)

System overview

System overview

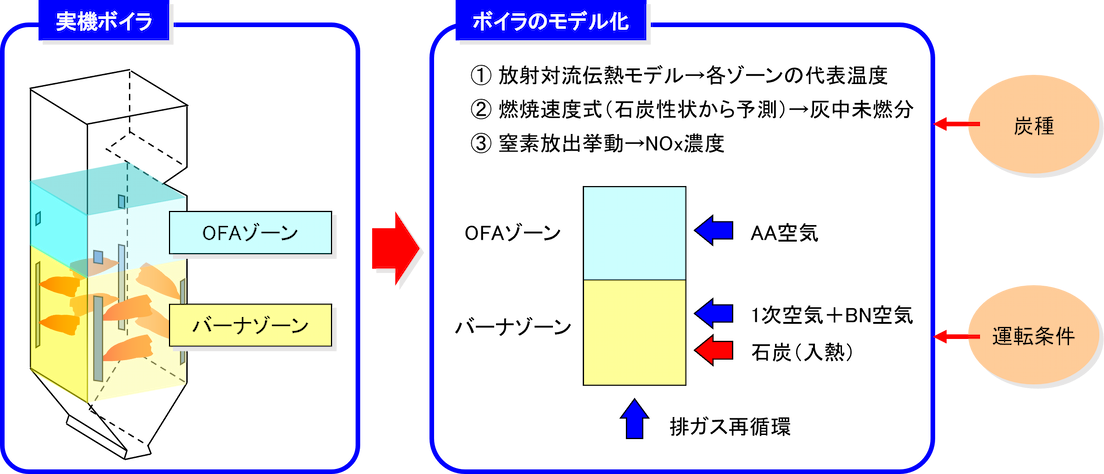

Why is it possible to accurately predict plant performance?

Why is it possible to accurately predict plant performance?

At our company, we use various tests and analyzes as well as engineering technology to predict actual equipment to develop highly reliable predictive indicators and incorporate them into our systems.

In particular, it has a built-in boiler model that predicts temperature distribution, unresolved content in ash, NOx concentration, etc. from the heat balance in the furnace, particle residence time, combustion rate, etc. , damper opening setting, etc.) can be predicted.

Case Study

Case Study

Main features

Main features

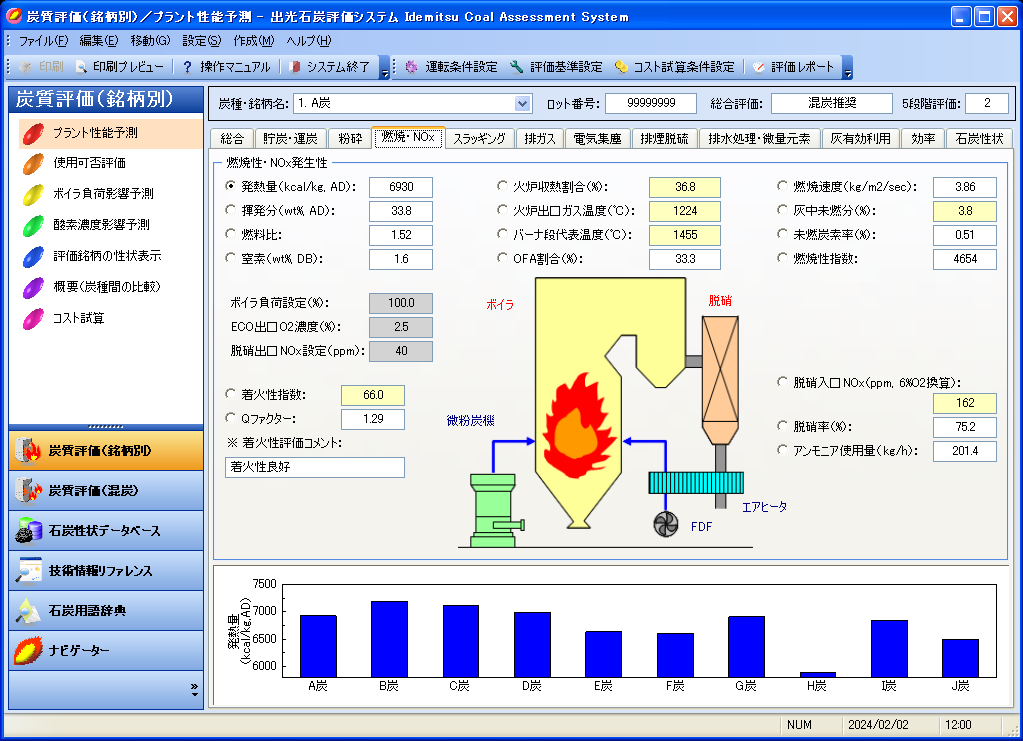

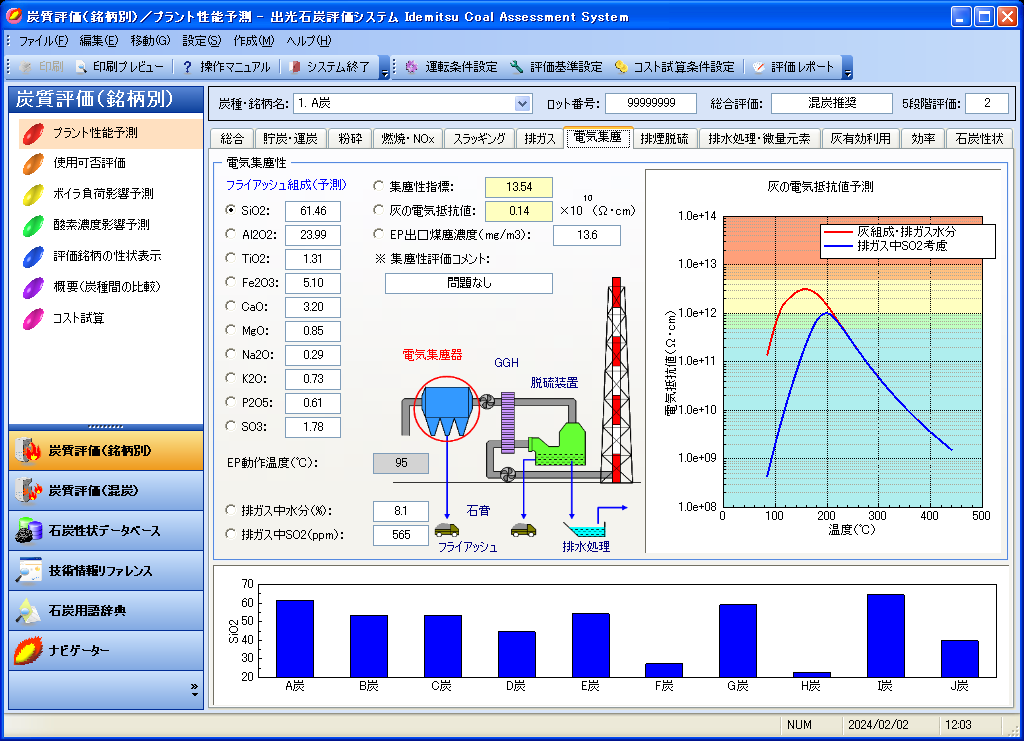

Plant performance prediction

Quantitatively examine plant performance for each coal type, including natural heat generation, handling, crushing, combustion, NOx concentration, slagging, air heater, electrostatic precipitator, flue gas desulfurization, wastewater treatment (trace elements), effective use of ash, and efficiency. Predict.

Flammability/NOx generation evaluation

Electrical dust collection evaluation

Usability evaluation

Displays the ranking of each item for each type of coal, as well as the overall evaluation.

Usability evaluation

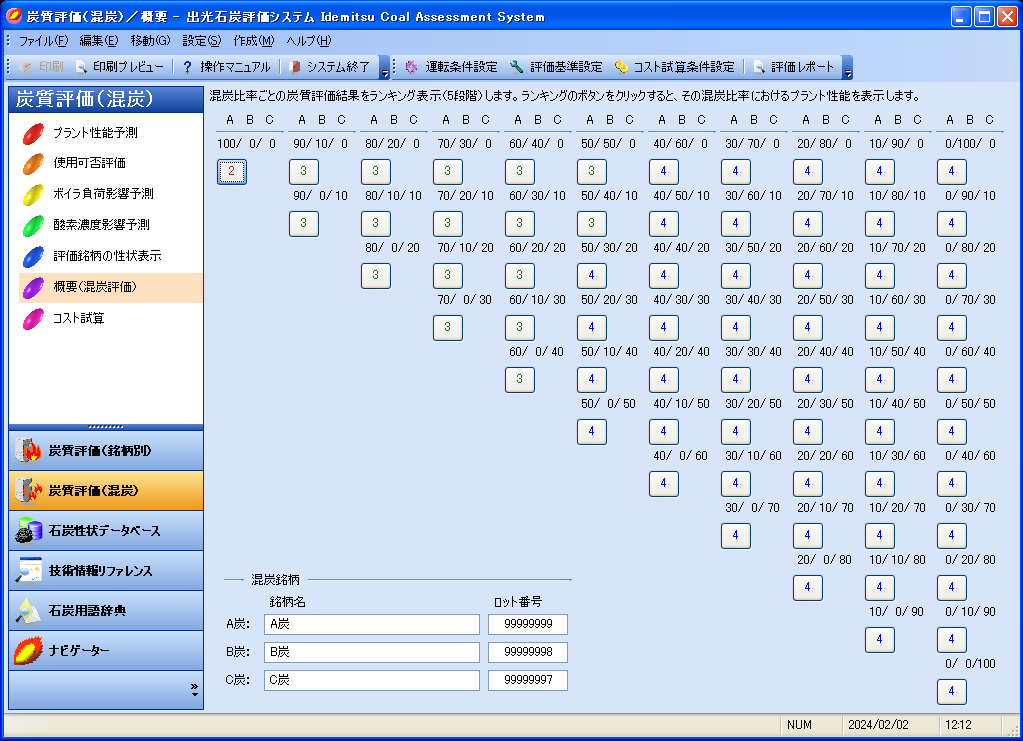

Optimal coal blend design

We evaluate the mixed coal of 2 to 3 types of coal in 10% increments and search for optimal conditions. We also judge whether or not it can be used under all mixed coal conditions and predict plant performance. It also supports changes in operating conditions.

Mixed coal evaluation

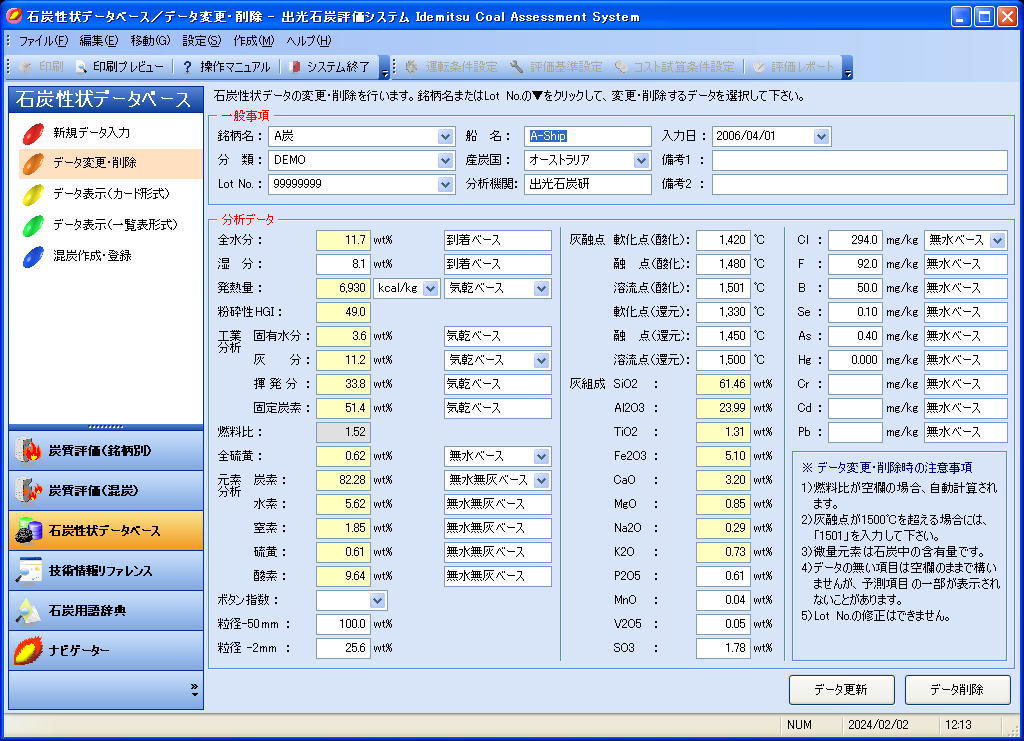

Coal property database

You can register new data, change/delete it, and create mixed coal. You can also view property data in card format or list format.

Data change/deletion

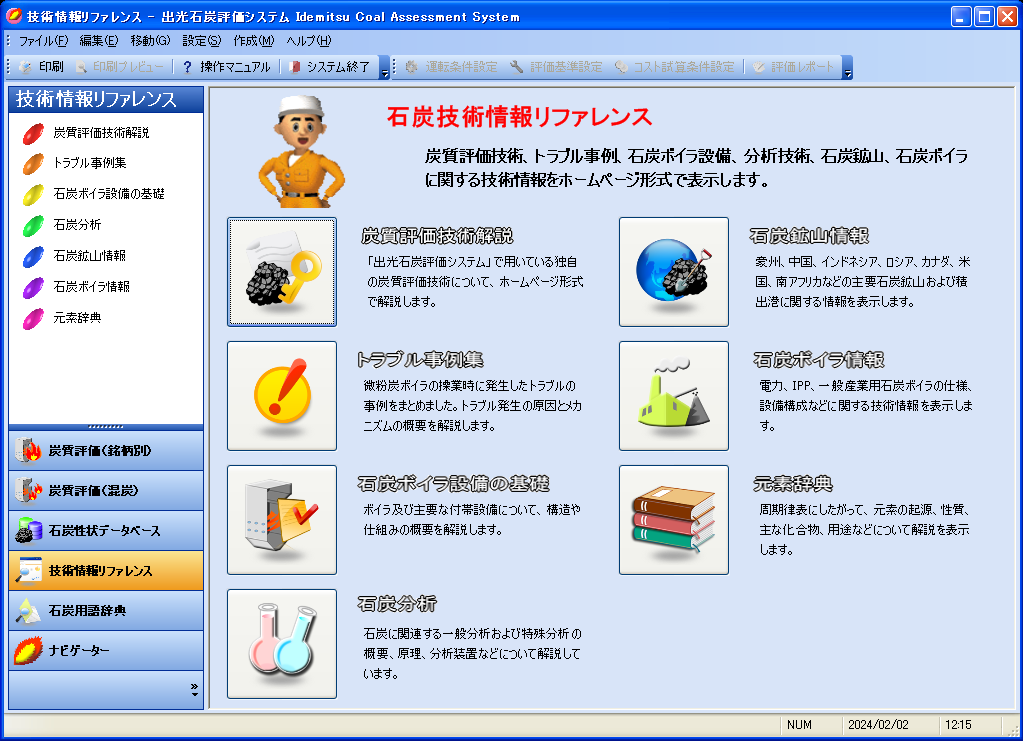

Various technical information

Technical information such as explanations of coal quality evaluation technology, trouble examples, coal analysis, coal mine information, coal boiler information, element dictionary, terminology dictionary, etc. can be viewed in the form of a homepage.

Technical information regarding calorific value

Monitoring camera inside high temperature furnace

You can see clear images of the inside of a coal boiler.

If a customer wants to observe the situation inside the furnace in order to consider countermeasures against problems with ash adhesion inside the furnace or to optimize combustion, we can conduct observation tests.

Features

Features

-

A high-resolution CCD camera is placed at the tip of the water-cooled + air-cooled probe.

-

The high-performance cooling system allows the area around the CCD camera to be maintained below 60℃ even in the high-temperature furnace.

-

The unique air blowing structure allows it to be used even in dusty environments.

Video of the inside of a pulverized coal boiler (our privately used boiler)

Video of the inside of a pulverized coal boiler (our privately used boiler)

Monitoring the upper burner from the hearth bottom: (1)

Lower CONC burner: (1)

Monitoring of ash accumulation at the bottom of the furnace: (1)

Clinker attached to screen pipe: (2)

Lower burner section: (3)

Clinker ash deposited at the bottom of the furnace: (3)

Coal/biomass analysis

We analyze the properties and practical performance of solid fuels such as coal and biomass.

From general properties to practicality analysis

From general properties to practicality analysis

We also perform special analyzes to more accurately determine the practical performance of coal, such as its combustibility, handling properties, and environmental adaptability.

List of analysis items

List of analysis items

General analysis

-

total water

-

Calorific value measurement

-

Grindability (HGI)

-

industrial analysis

-

elemental analysis

-

Sulfur content analysis in ash

-

Total sulfur analysis

-

Chlorine/fluorine analysis

-

Crucible expansion test (CSN)

-

Ash melting temperature measurement

-

Coal ash composition analysis

-

particle size test

special analysis

-

trace elements

-

Sulfur by form

-

SEM/EDS

-

Low temperature ashing treatment

-

Mineral identification/quantification

-

Particle size distribution

-

true specific gravity

-

Bulk specific gravity

Practicality evaluation/test

We conduct predictive evaluations and plant tests of combustibility, crushability, handling, spontaneous heat generation, etc. in actual boilers.

Environmental protection technology product Coal dust scattering prevention agent “Idemitsu Coal Clean WA-500”

This is a "dust scattering prevention agent" that can be used for coal and petroleum coke powder. Effective in small amounts and prevents coal dust from scattering. It contributes to improving the working environment in coal yards and factories and reducing the impact on the living environment.