Handling performance evaluation

Problems that frequently occur when handling coal include clogging in the hopper and blockage in the chute. Although it is difficult to predict and evaluate the discharge and sticking properties of coal based on coal properties, it is possible to quantitatively evaluate it by conducting accurate tests.

durum test

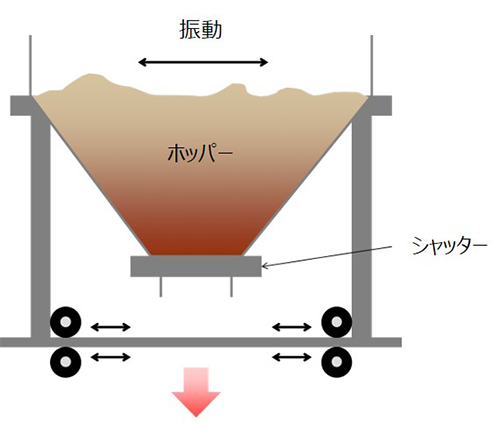

The durum test is a test that primarily evaluates discharge performance from storage tanks, etc. After putting 12 kg of coal (wet coal base) into a stainless steel hopper with an angle of 45 degrees, it is vibrated from side to side, the shutter at the bottom is opened after 10 seconds, and the time it takes for the entire amount of coal to fall is measured. By performing similar tests with varying total water content, the relationship between total water content and drainage time can be obtained.

durum test equipment

Measure discharge time

Example of durum test results

Adhesion cohesion test

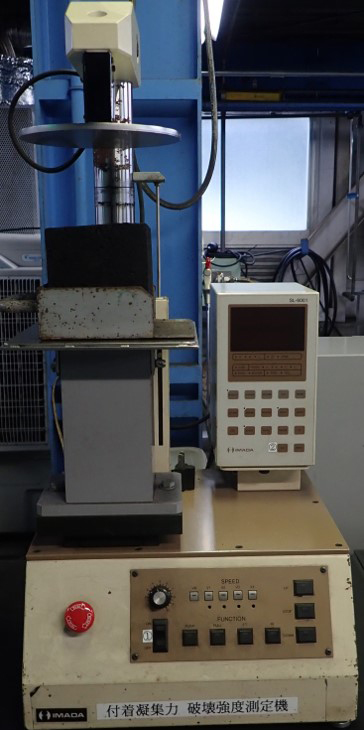

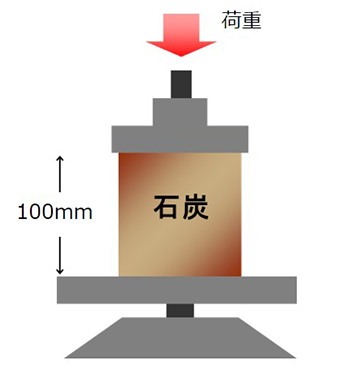

The adhesion cohesive force test is a test that mainly evaluates the adhesion of coal to each other in the chute at the transfer section of the belt conveyor. A -5mm portion of the coal sample is taken and molded under a load of 4,000kgf to create a cube approximately 100mm square. Next, the molded product is destroyed using a uniaxial compression tester, and the fracture strength at that time is measured. Coal that has a large adhesion cohesive force is more likely to form strong clumps when it hits the chute wall.

Adhesion cohesion test device

Adhesion cohesion measurement

Example of adhesion agglomeration test results