Lubricants Research Laboratory

About Lubricants Research Laboratory

Since its opening in 1968, Lubricants Research Laboratory has been working with customers to constantly research and develop cutting-edge lubricants and lubrication technologies. The products developed at Lubricants Research Laboratory range from automotive lubricants to industrial lubricants and greases. Recently, with the SDGs in mind, the Institute has been focusing on developing products that are friendly to both the earth and workers, such as carbon neutral products and improved working environments.

Lubricants Research Laboratory will continue to anticipate issues from the customer's perspective, promote "the creation of technology that makes dreams come true" using the lubrication technology it has cultivated over many years, and support innovation at "manufacturing sites."

Related Links

Main initiatives/research contents - 01

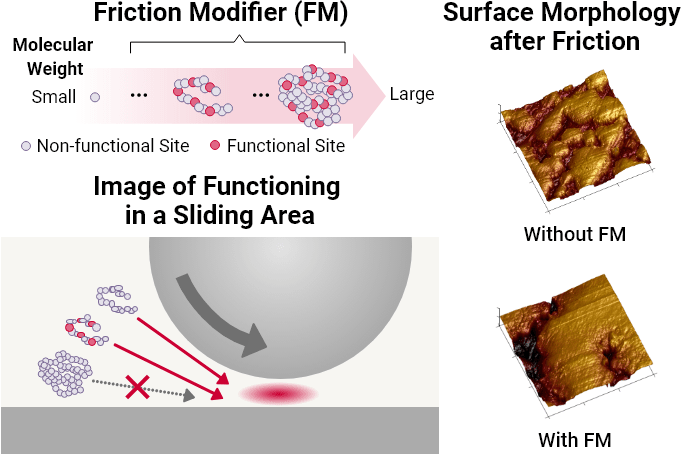

Development of fuel-efficient lubricant for automobiles

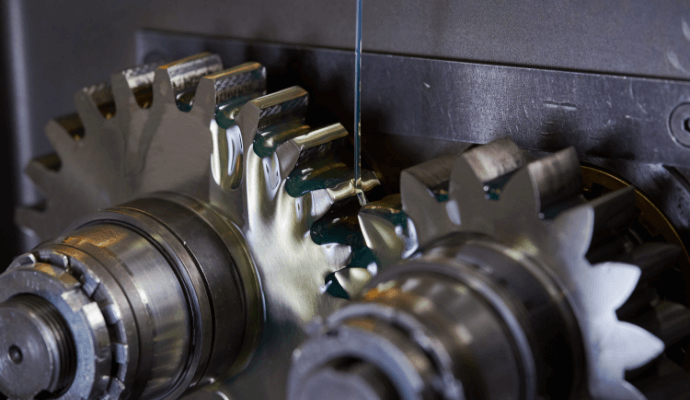

Technological innovation in the automotive industry is accelerating against the backdrop of global targets for reducing CO2 emissions. Lubricants are no exception, and even higher performance is required. At Lubricants Research Laboratory, we are working on new technological developments through lubricant design at the molecular level, which fundamentally controls the physical and chemical interactions involved with lubricants.

For example, in engine oil, lowering the viscosity improves fuel efficiency at high engine speeds, but at low engine speeds, sufficient oil film cannot be formed and metal-to-metal contact increases, resulting in poor fuel efficiency. Therefore, we focus on friction modifiers that can reduce friction in a characteristic way in mixed lubrication and solid lubrication regions where metal-to-metal contact increases, and have established a technology to evaluate the behavior of friction modifiers placed in nanoscale gaps formed between solid surfaces. We have selected and developed engine oils that incorporate optimal friction modifiers based on their molecular level functions. In addition, we are working to develop next-generation engine oils that visualize and control the molecular behavior of polymers contained in oils by utilizing the large-scale synchrotron radiation facility (SPring-8).

Main initiatives/research contents - 02

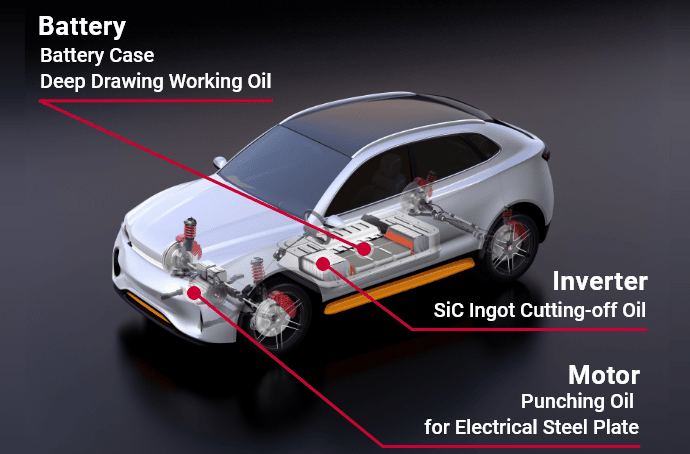

EV conversion of automobiles and metal processing oil

With the shift to EVs in automobiles, the main components of parts will change from engines to motors, batteries, and semiconductors, but this will also bring about changes in the needs for metalworking fluids in the parts processing process. At our research institute, we are working on the development of punching oil that aims to optimize the post-machining process for punching electrical steel sheets, which are used as motor core materials to contribute to higher efficiency and higher output density of motors. In addition, during the deep drawing process of lithium-ion battery cases installed in EVs, deep drawing oil is used to stabilize and improve the quality of molded products, and is used in the inverter that converts the battery's DC power to AC to supply the motor. We are also actively working on the development of next-generation products, such as ingot cutting oil for SiC, which is a power semiconductor material that can be used.

Main initiatives/research contents - 03

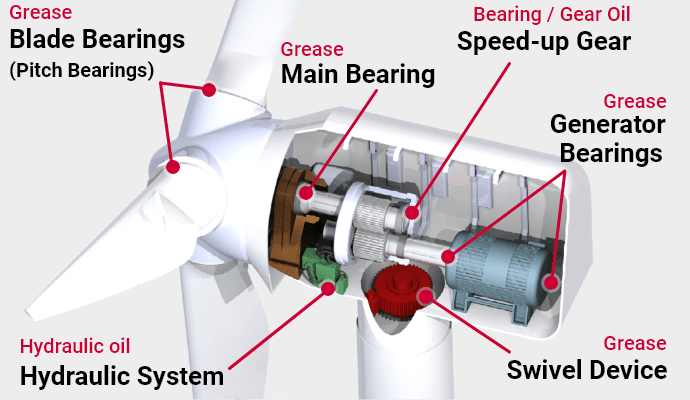

Development of industrial lubricants (for wind power generation)

Based on the concept of "supporting life and industry around the world," our research institute develops industrial lubricants that meet social trends and the latest customer needs. We develop No. 1 and only 1 lubricants that match the evolution of machinery, from large industrial machinery such as power generation equipment and construction machinery to home appliances such as air conditioners and DVD/BD. In recent years, we have been particularly focused on developing lubricants to help realize a decarbonized society. Among them, wind power generators, which are expected to be the key to achieving carbon neutrality by 2050, use bearing/gear oil, hydraulic oil, and grease. In order to reduce the running costs of wind power generation and ensure stable operation over the long term, we believe that it is essential to extend the life of lubricants and to make mechanical equipment including lubricants maintenance-free. Recently, we have been working in collaboration with industry, academia, and government to develop lubricants that will contribute to the advanced use of wind power generation.

Main initiatives/research contents - 04

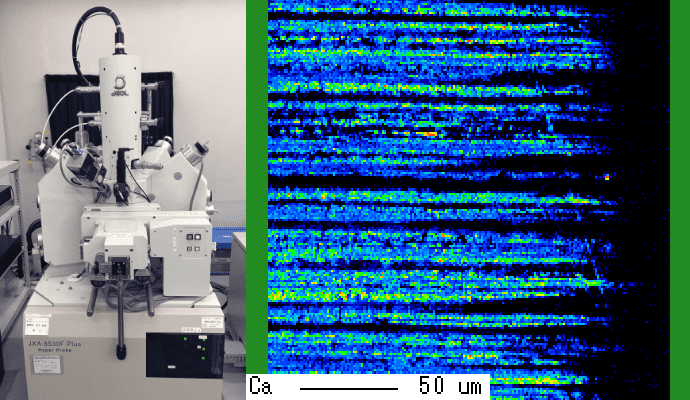

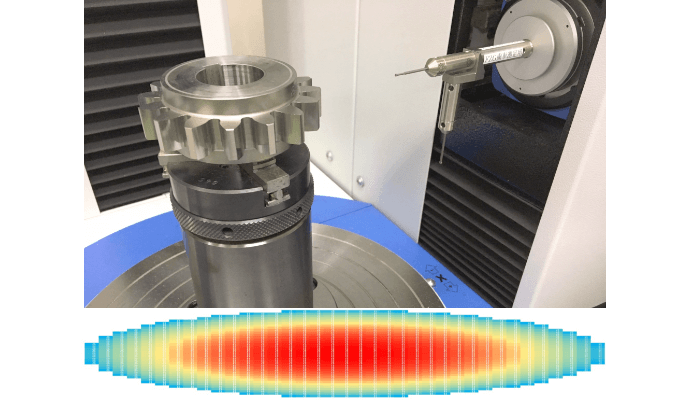

Test analysis and performance evaluation of lubricating materials ~ Mechanism elucidation and digital utilization ~

Various lubricants, including lubricating oil and grease, contribute to the performance and longevity of mechanical equipment by reducing friction and wear, cooling, and surface protection. In addition to carefully analyzing the properties of lubricants, changes in chemical composition during deterioration, film formation on friction surfaces, and micromorphological changes, we also use technology to measure and analyze the harsh conditions of friction surfaces to understand the lubrication mechanism. We provide quick feedback on estimation, base material selection, and performance evaluation, contributing to rapid product development.

Furthermore, in recent years, we have been working on the development of technologies that not only improve the efficiency of development operations but also contribute to improving the productivity of our customers, such as analyzing the causes of abnormalities using AI, searching for new compounds, and remote monitoring systems using the cloud. Masu.

Main initiatives/research contents - 05

Development of new base materials for lubricating oil

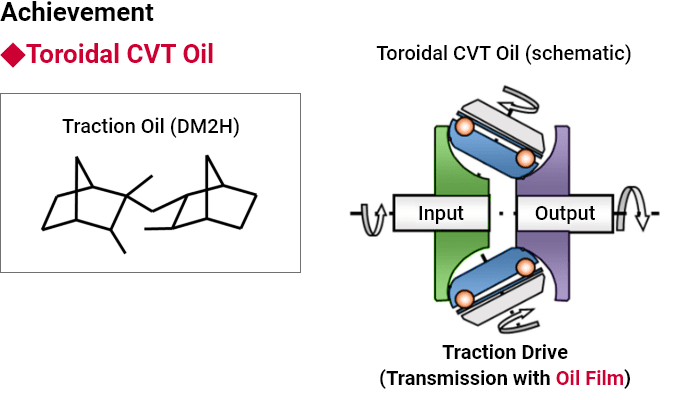

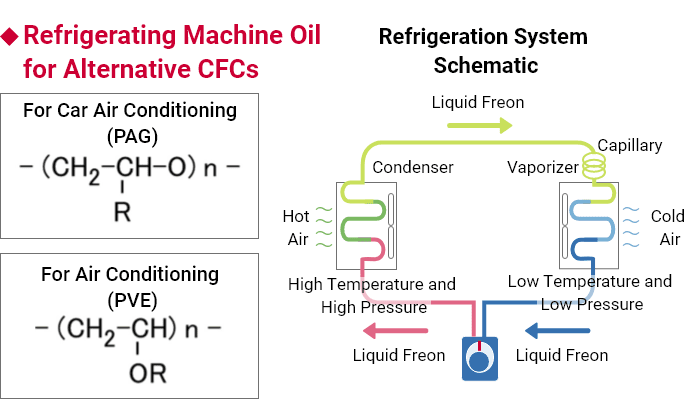

Toward the realization of carbon neutrality society we must continually develop high-performance, high-value-added, and environmentally friendly products, but there are cases where commercially available base materials cannot meet these needs. Therefore, our institute is developing new base materials for high-performance lubricants quickly while investigating the "know why." We use organic synthesis, computational chemistry, and industrialization as our core technologies, and by combining these at a high level, we respond to the diverse and potential needs of our customers in detail. In our laboratories, we synthesize and evaluate various compounds, and use molecular modeling and simulation software to predict how the molecular structure is related to the physical properties and behavior of the base material, and design optimal compounds. We then use pilot plant facilities to manufacture tens of liters of samples of the optimal compounds found in the laboratory in a short delivery time and provide them to customers, responding quickly. Major achievements of our institute so far include the world's first high-performance traction oil installed in toroidal CVT vehicles, car air conditioner oil that boasts a high global market share, and air conditioner refrigeration oil, which are contributing to the realization of a fuel-efficient, low-carbon society.

access

| Address | 24-4 Anesakikaigan Ichihara City, Chiba Prefecture, 299-0107 |

|---|