Adhesive base material

Adhesive base materials are raw materials for adhesives and adhesives used to fix and bond parts together.

"Hydroxyl Terminated Poly butadiene™" is a liquid polymer with a highly reactive hydroxyl group at the end of the molecule.

Like general polyols, which are raw materials for polyurethane, it is easily cured by reaction with various isocyanate compounds and becomes a high-quality urethane elastomer (rubber elastic body).

In addition, we also have the polyisoprene type "Hydroxyl terminated liquid Poly isoprene™" and the polyolefin type (hydrogenated type) "Hydroxyl terminated liquid Poly olefin™". All grades do not contain easily hydrolyzable groups in their main chain structure, making it possible to design materials with excellent hydrolysis resistance.

In addition, "I-MARV™" (I-MARV: hydrogenated petroleum resin) is a colorless and transparent petroleum resin originally developed based on the polymerization and hydrogenation technology that Idemitsu Kosan has cultivated over many years.

When I-MARV is used as a hot melt adhesive (HMA), it exhibits a balanced performance in heat resistance, cold resistance, and adhesion. In addition, I-MARV can be added to BOPP film* to improve transparency, rigidity, and water vapor barrier.

*: BOPP (biaxially oriented polypropylene) film: A film widely used for manufacturing product labels, laminates, and packages.

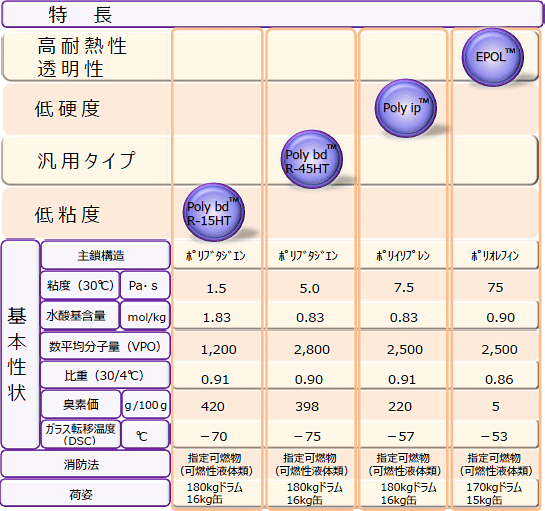

Product line-up

Properties of each grade

*The data listed on this page are representative examples of measured values under specific conditions, and are not standard or guaranteed values.

*Please note that the contents of this page are subject to change without notice due to improvements.

Search for materials by properties

water resistance

Since it does not contain ether or ester groups, it has excellent water resistance, chemical resistance, low moisture permeability, low water absorption, heat and humidity resistance, and moisture resistance.

Learn more

Electrical properties

It has electrical insulation properties and low dielectric properties comparable to epoxy resin and silicone rubber.

Learn more

Cold resistance

The embrittlement temperature of the cured product is -60℃ or lower, and it has excellent cold resistance.

Learn more

High reactivity

It has high reactivity because the terminal hydroxyl group is a primary hydroxyl group.

Learn more

rubber elastic

The main chain structure has 80% 1,4 bonds, and the cured product exhibits good rubber elasticity.

Learn more

optical properties

It has excellent optical properties and can be applied to the optical field.

Learn more

Purpose

Civil engineering and construction

Coating film waterproofing materials, sheet waterproofing materials, spray waterproofing materials, double glazing sealants, flooring floor adhesives, elastic paving materials for tennis courts and athletic fields, painted flooring materials, concrete protection materials, slab track filling materials, paints (exterior), expressway finger joints, suspension bridge cable joints

electrical insulation material

Potting electrical components for automobiles, motorcycles, etc., coating printed circuit boards, impregnating and potting transformers, coils, and capacitors, joint sealing of cables.

car

Damping materials, bumpers, sealing materials, outer panels such as fenders (nylon RIM), brake shoes

anti-corrosion material

Linings for swimming pools and water tanks, corrosion protection for steel pipes and sheet piles, corrosion protection injection materials for cables

Others

Cloth shoe adhesives, urethane soles, asphalt foam, shock absorbers, rubber chip binders, modifiers and reactive plasticizers for urethane, epoxy, nylon, rubber, etc., packing materials for carpets, dispersants and resin modifiers for ferrite, etc. Materials and low-hardness elastomer products (rolls for OA equipment, vibration damping materials, etc.), adhesives and adhesives (polyolefin, EPDM materials, etc.), sealing materials, lining materials, optical field (optical transparent adhesive (OCA), ultraviolet rays) (UV) as a curing resin compounding agent)