Rubber elasticity of adhesive base material

The main chain structure of Idemitsu Kosan products has 80% 1,4 bonds, and the cured products exhibit good rubber elasticity.

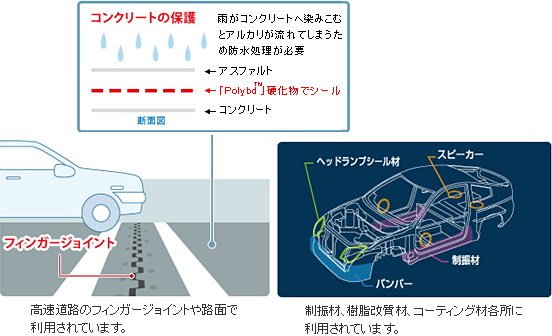

In the civil engineering and construction fields, it is used in double-glazed glass sealants, flooring adhesives, elastic paving materials for tennis courts and athletic fields, plastered flooring materials, slab track filling materials, finger joints for expressways, cable joints for suspension bridges, etc. used.

In automobiles, it is used as vibration damping materials, bumpers, sealing materials, outer panels such as fenders (nylon RIM), and brake shoes.

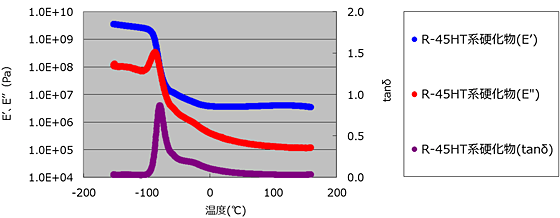

Dynamic viscoelasticity measurement

|

R-45HT series cured product |

R-15HT series cured product |

Hydroxyl terminated liquid Poly isoprene™ series Hardened material |

Hydroxyl terminated liquid Poly olefin™ Series Hardened material |

|

|---|---|---|---|---|

| Tg (α relaxation) | -87.3℃ | -73.6℃ | -64.9℃ | -59.3℃ |

| E' (@25℃) | 3.6E+06 | 5.6E+06 | 2.4E+06 | 4.7E+06 |

| tanδ (maximum value) | 0.87 | 0.39 | 1.08 | 0.87 |

| Shore A hardness | 52 | 60 | 42 | 57 |

*Each cured product uses liquid modified MDI as a curing agent.

Mixing conditions: [NCO]/[OH]=1.05

Curing conditions: Press 120℃ x 1 hour + Post curing 70℃ x 15 hours

H type peel test (JIS1439 standard)

Field: interfacial failure, cohesion: cohesive failure, unit: N/cm 2

| Adherent | R-45HT type cured product | R-15HT type cured product | Hydroxyl terminated liquid Poly isoprene™ hardened material | Hydroxyl terminated liquid Poly olefin™-based hardened material |

|---|---|---|---|---|

| polycarbonate |

80 Kai; 3 Ko; 2 |

122 Kai; 5 |

91 stiff; 5 |

140 stiff; 5 |

| Aluminum |

38 Kai; 5 |

61 Kai; 5 |

28 stiff; 5 |

77 Kai; 5 |

| Glass (Rigid) |

63 Kai; 5 |

98 Kai; 4 Ko; 1 |

70 Kai; 1 Ko; 4 |

62 Kai; 2 Ko; 3 |

Curing agent: liquid modified MDI ([NCO]/[OH]=1.05), catalyst: DBTDL 0.05phr