Tokuyama Complex | Safety Initiatives

Safety measures at Complex not only help maintain smooth production activities, but are also a major factor in determining international competitiveness. Furthermore, accidents that cause inconvenience to the local community must never occur. At Idemitsu Kosan, safety and maintenance personnel work together to ensure accident-free operations. All equipment that operates without rest is periodically shut down and every single pipe is inspected for malfunctions or abnormalities. In addition, each Complex has its own fire engine, and regular training is conducted in preparation for any emergency.

Prioritize safety measures

Idemitsu Kosan is aware that ensuring safety is the foundation of its business, and so the entire company is working to ensure safety. At Complex, TPM activities are being implemented to prevent accidents, including preventing equipment trouble by managing equipment based on the causes of deterioration, and preventing operational errors by considering human factors. In addition, we are working together with partner companies to implement steady safety activities to prevent accidents and troubles.

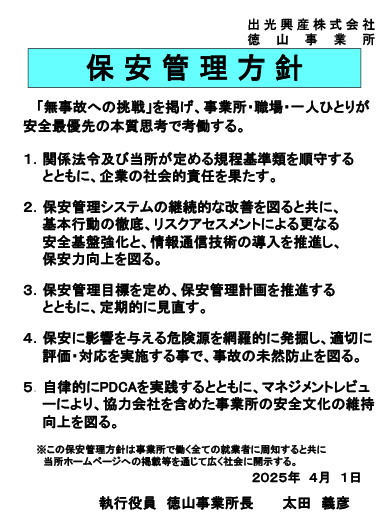

Security management policy

From April 1, 2006, we began operating a security management system based on the "Security Management Regulations" with the aim of ensuring the safe operation of Complex and the safety of our employees, as well as maintaining and improving the level of security. Did.

Security means preventing accidents and malfunctions, preventing the spread of disasters, and preventing health problems, minimizing damage to people and property, and ensuring the safety of workers in Complex and the public.

Security management refers to the formulation, implementation, evaluation, and improvement of plans to ensure security based on security management policies.

A security management system is a system that establishes security management policies and security management goals in order to promote security management activities, and continuously formulates, implements, evaluates, and improves security management plans in order to achieve them. This mechanism includes ensuring that the structures, responsibilities, procedures and Resources (human resources, budget, materials and expertise) are in place to establish, implement, achieve, review and maintain the security management policy.

Specific requirements

The specific requirements of this Complex are defined in the safety management regulations and are communicated to employees who carry out safety management activities in the Safety and Disaster Prevention Committee, Safety Council, etc.

Definition (Security Management Regulations Article 3)

This refers to the High Pressure Gas Safety Act and the orders thereunder, as well as requirements that our Complex specifies itself. Note that self-specified requirements refer to these regulations and related regulations.

Related laws and regulations

High Pressure Gas Safety Act, Industrial Safety and Health Act, Fire Service Act, Petroleum Industrial Complex Disaster Prevention Act, Poisonous and Deleterious Substances Control Act, Act on Regulation of Radioisotopes, etc., Shunan City Fire Prevention Ordinance, Electricity Business Act, Measurement Act, Construction standard method

Related regulations

-

Special regulations

Safety management regulations, high pressure gas certification safety inspection regulations, high pressure gas certification completion inspection regulations, harm prevention regulations, safety education plan, prevention regulations, disaster prevention regulations, radiation hazard prevention regulations -

Outline

Complex operation guidelines -

Regulations

Equipment management regulations, operation management regulations, safety and health management regulations

Partner company work rules

Disaster prevention equipment

| fire engine | 6 units |

|---|---|

| fire pump | 11 units |

| Oil fence (B type) | 3,520m |

safety activities

Security capability evaluation by a third party

Since 2017, the Tokuyama Complex has undergone a third-party assessment, the Safety Competency (Safety Infrastructure and Safety Culture) Assessment, conducted by the Safety Competency Improvement Center of the Japan Society for Safety Engineering.

In the February 2023 results, we received high marks for achieving or exceeding the standard level in each evaluation category for "safety foundation" and "safety culture," in recognition of the success of our ongoing efforts to establish a safety management system, including risk assessment, as well as the formulation, implementation, and evaluation of plans, and our ongoing improvement activities.

On the other hand, we have received advice and insights on several items, which we have identified as areas for improvement at our Complex and are working to implement improvements in a planned manner.

Safety environment improvement dialogue

Director's speech

On-site dialogue

Safety Patrol Complex

Manager Tour

“Idemitsu Tokuyama Safety Council” regular general meeting

Explanation of basic safety policy

Activity plan explained by the cooperative association secretariat

Idemitsu Tokuyama Safety Council Safety Conference

Greetings from the Safety Council Chairman

Scene from the venue

Various safety activities

Cooperation Association Safety Conference

SDM construction begins KY Patrol

Safety confirmation by visiting the ship

Study session on “Risk Assessment”