Chiba Complex | Overview

Overview

| Beginning of operation | 1963 |

|---|---|

| Number of employees | 903 (as of April 1, 2025) |

| Site area | 1.15 million tsubo (3.82 million m2) |

| Location/Access |

History

Refinery

| 1963 | Refinery completed |

|---|---|

| 1967 | Heavy oil desulfurization equipment completed (world's first) |

| 1970 | Completion of lubricating oil refinery equipment |

| 1971 | Completion of fluid catalytic cracking equipment |

| 1985 | Completion of lubricating oil hydrodewaxing equipment |

| 1989 | Coal boiler completed |

| 1992 | Completed construction of a 50,000 ton LPG low temperature storage tank. |

| 1993 |

Completed construction of reformed gasoline fractionator Completion of debenzene removal equipment (first in the industry to obtain Eco Mark) |

| 1994 | Obtained ISO9002 certification (first in the oil industry) |

| 1995 | Light oil deep desulfurization equipment completed |

| 1996 | TPM Excellence Award Winner |

| 1997 | ISO14001 certification obtained |

| 2000 | Completion of lubricant distribution center (concentration of shipping bases) |

| 2002 | Transition to ISO9001:2000 certification |

| 2003 | Completed carbon dioxide supply facility to Kokusai Tanso Co., Ltd. |

| 2004 |

Completed cracked gasoline desulfurization equipment Completed naphtha precision distillation equipment |

| 2006 | Light naphtha reformer equipment restarted |

| 2009 | Butene transformation equipment completed. |

| 2009 | Chiba Bio Terminal opened |

| 2010 | Lubricating oil filling station completed |

| 2011 | Completion of automatic lubricant warehouse |

| 2017 | Chiba Complex opened |

petrochemical factory

| 1975 | Chiba factory completed (high-density polyethylene equipment, stopped in 2013) |

|---|---|

| 1977 | Completion of aromatic production equipment and first polypropylene production equipment |

| 1981 |

The first polystyrene manufacturing plant was completed (suspended in 2013). Established Resin Research Institute (currently Performance Materials Laboratories) |

| 1982 | Completion of styrene monomer manufacturing equipment |

| 1985 | Completed ethylene manufacturing equipment, completed construction of the first polycarbonate manufacturing equipment (stopped in 2015) |

| 1986 |

Composite resin factory completed. Linear low-density polyethylene production equipment completed (stopped in 2014) |

| 1988 |

The second polypropylene manufacturing facility was completed. Opened the Applied Materials Research Institute (now Performance Materials Laboratories) |

| 1989 | Completed α-olefin manufacturing equipment and cyclohexane manufacturing equipment. |

| 1990 |

Completion of second polycarbonate manufacturing facility (suspended in 2014) Process Research Center (now Technology & Engineering Center) opened. |

| 1991 |

Completed construction of bisphenol A manufacturing equipment and third polypropylene manufacturing equipment. Completion of second polystyrene manufacturing equipment (stopped in 2003) |

| 1992 | ISO9002 certification obtained |

| 1996 |

Syndiotactic polystyrene manufacturing facility completed ISO14001:1994 certified Transition to ISO9001:1994 certification |

| 1999 |

TPM Excellence Award Winner (Sponsored by Japan Plant Maintenance Association) |

| 2001 | Completion of second composite resin factory |

| 2002 |

Received TPM Excellence Continuation Award (Sponsored by Japan Plant Maintenance Association) Compound center opened |

| 2004 | Opened the General Development Center (now Performance Materials Laboratories). |

| 2006 | Syndiotactic polystyrene production equipment restarted |

| 2008 | Transition to ISO14001:2004 certification |

| 2012 | Completion of soft polypropylene production equipment |

| 2017 | Chiba Complex opened |

Chiba Complex

| 2017 | Chiba Complex opened |

|---|---|

| 2018 | The former Refinery and Chiba Plant were integrated into Chiba Complex, which was certified ISO14001:2015 and ISO9001:2015. |

| 2020 | Certified as a specific certified business (commonly known Complex) |

| 2021 | Demonstration facility begins operation for commercial production of solid electrolytes for next-generation batteries |

Features

Idemitsu's largest Complex

Chiba Complex produces approximately 20% of Idemitsu's total petroleum products, refining approximately 10 million kL of crude oil each year and delivering the products.

Refinery and petrochemical plant integrated

Idemitsu Chiba is an integrated Complex that combines Refinery and a petrochemical plant.

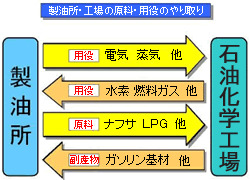

Refinery and petrochemical plants are organically linked by 50 pipelines, and we are working to achieve efficient management by promoting the joint use of equipment and facilities and the optimal use of fractions and utilities.

Exchange of raw materials and services between Refinery and factories

Pipelines connecting Refinery and petrochemical plants

International standard environmental and quality management system

Chiba Complex has obtained ISO14001 and ISO9001 certification, and is promoting environmental management and quality control activities based on international standard management systems.

| 1993 | Installed a new debenzene removal device ahead of the industry (obtained the industry's first Eco Mark in 1996) |

|---|---|

| 2001 | Start of supply of low-sulfur diesel oil to Tokyo (advance response to legislation in 2004) |

| 2003 | Achieving zero waste emissions |

| 2004 | Construction of gasoline desulfurization equipment (compatible with sulfur-free gasoline) |

| 2005 | Aiming for zero waste landfill disposal |

Consecutive awards for excellence in promoting energy conservation

Actively engaged in energy-saving activities and won excellence awards at competitions sponsored by the Ministry of Economy, Trade and Industry from 1986 to 2011. Awarded for 25 consecutive years . We are the only company in Japan to have received this award consecutively for over 20 years.

Management improvement activities involving all employees

At Idemitsu Chiba, we promote cross-divisional improvement activities and have all employees demonstrate their technical capabilities to tackle challenging issues, thereby acquiring high field skills and improving operational management, equipment management, quality control, and safety. We have built a high level of reliability in management, environmental management, etc.