Chiba Complex

Chiba Complex is the largest plant in the Idemitsu Group, and while it is engaged in the "refining and manufacturing of Petroleum" and "manufacturing of petrochemicals," it also manufactures high-value-added products such as "Advanced materials & Performance Chemicals" "functional chemicals," and "functional resins." The surrounding area is Complex to a number of related Complex, including the manufacturing and technology department centers and research laboratories, Lubricants Research Laboratory, the coal import base, and the plastic research and development department, making the Chiba area Idemitsu's most important base for development, production, and logistics.

Introduction of Chiba Complex

Overview

Refinery began operations in 1963. As our core Complex, it has introduced many cutting-edge devices and systems to meet robust demand, particularly in the Tokyo metropolitan area. The petrochemical plant began operations in 1975. It produces ethylene and other resins, including polypropylene. The site also includes Performance Materials Laboratories and Technology & Engineering Center, creating a production system that is directly linked to user needs.

Learn more

Equipment capacity

Refinery includes an atmospheric distillation unit with a crude oil processing capacity of 195,000 barrels per day, as well as a lubricant refining unit, making it Idemitsu's only lubricant production site.

The petrochemical plant includes an ethylene production facility with an annual production capacity of 374,000 tons, and an aromatics production facility that produces benzene and paraxylene.

Learn more

Site overview

Taking full advantage of the benefits of integrating Refinery and petrochemical plants, we have achieved an efficient and integrated production system, from oil refining to the production of plastic materials.

Learn more

Manufacturing flow

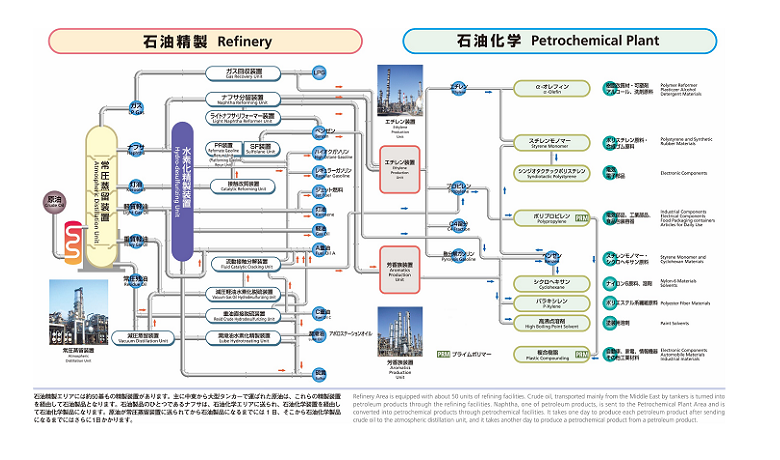

At Refinery, crude oil is heated to about 360℃ in a heating furnace and then sent to an atmospheric distillation unit, where it is separated into fractions that will become petroleum products such as LPG, gasoline, naphtha, diesel, and heavy oil, taking advantage of the difference in boiling points.The product is then made into a product through various processes.

Petrochemical plants use naphtha, LPG, and heavy oil sent via pipeline from Refinery as raw materials to produce everything from monomers that serve as petrochemical raw materials to polymers (synthetic resins) for plastic molding processing.

Learn more

Chiba Complex Initiatives

Safety initiatives

All employees at our Complex work together to carry out activities to prevent serious accidents, based on the principle of "safety first."

Learn more

Environmental Initiatives

With the aim of "creating Complex that is trusted by local people,'' we established a green belt and started out as a "park factory'' with lush greenery that takes into consideration the local landscape and environment.

Learn more

Commitment to quality

We have obtained ISO certification, which is an international standard for quality assurance, and are striving to "supply quality products economically and stably.''

Learn more

Initiatives with local communities

Since its establishment, our Complex has consistently followed our founder's philosophy of "working together with the local community" and has valued our ties with the local community, engaging in a variety of community activities as a corporate citizen.

Learn more

Learn about Chiba Complex through video

About Chiba Complex

An overview of Chiba Complex began operations as Refinery in 1963, as well as "How petroleum products are made,'' "How products are delivered,'' "Manufacture and supply of lubricating oil,'' and "How petrochemicals are made.'', "Surrounding Related Facilities'', "Initiatives for Safety and Stable Work'', "Initiatives for Environmental Conservation'', and "Together with the Local Community'' are introduced through videos.