Performance Materials Laboratories

About Performance Materials Laboratories

The mission of Performance Materials Laboratories, which is the business division research institute of Advanced materials & Performance Chemicals Department, is to conduct research and development and develop applications for engineering Functional materials, Advanced materials & Performance Chemicals such as adhesive base materials and liquid rubber, which are positioned as high-performance materials, and functional coating materials. Based on the technologies accumulated over many years in catalysts, synthesis, material design, compounds, practical evaluation, etc., we provide solutions to various needs from the market and create new value for the next era.

Main initiatives/research contents - 01

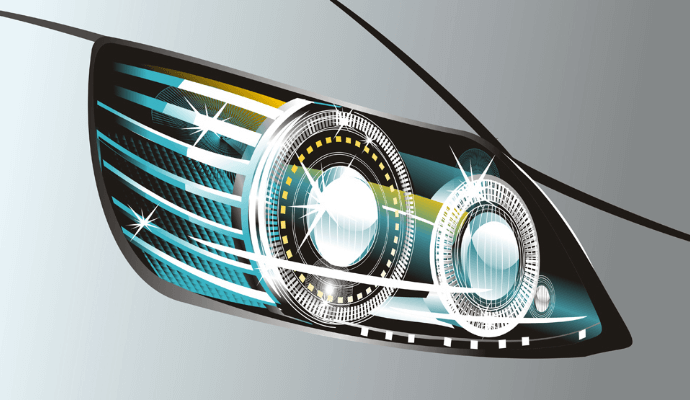

engineering plastics

We offer engineering plastics such as TARFLON™ (polycarbonate) and XAREC™ (syndiotactic polystyrene) as well as thermosetting resins such as Igran™. By further enhancing functionality through alloy compounding, we are able to meet the needs of our customers in a wide range of applications, including automotive, IT equipment, and lighting.

Related Links

Main initiatives/research contents - 02

Advanced Materials & Performance Chemicals

In terms of Advanced materials & Performance Chemicals, we offer unique materials such as I-MARV ™ (hydrogenated petroleum resin), an adhesive base material; liquid rubber with hydroxyl groups at both ends of the molecule, Hydroxyl Terminated Poly butadiene™, Hydroxyl terminated liquid Poly isoprene™, Hydroxyl terminated liquid Poly olefin™, and LINEALENE ™ (alpha-olefin) with terminal double bonds.

Related Links

Main initiatives/research contents - 03

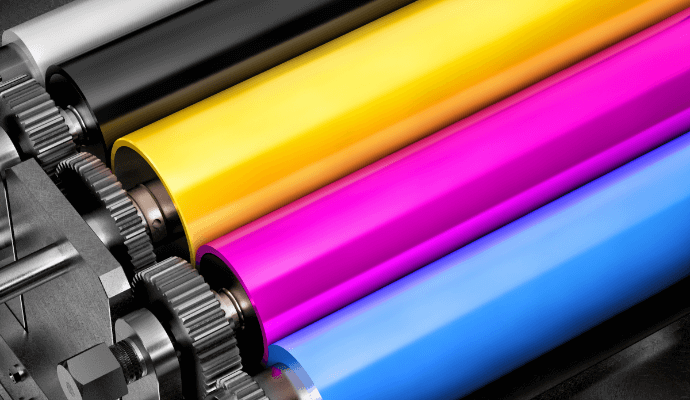

Functional coating material

As for functional coating materials, TOUGHZET™ (special polycarbonate), which has excellent abrasion and heat resistance, is used as a surface coating resin for electrophotographic photoconductor (OPC) drums, and polyaniline, a conductive coating agent that can control conductivity over a wide range, is used in the electronic materials field.

Related Links

Main initiatives/research contents - 04

Co-creation with customers

In addition to developing materials and applications that reflect customer needs, we also help customers realize their products through technical support in the commercialization process, including design support using CAE, flow analysis, and warpage and stress analysis.

Our open lab, the "Development Site," is equipped with high-performance injection molding machines and practical evaluation equipment, and we promote collaboration with customers in prototyping, product evaluation, and other areas.

In addition, the presentation site displays examples of applications of Functional materials, allowing visitors to experience the breadth of our business activities and to use the site as a forum for co-creation with customers to generate new development themes.

access

| Address | 1-1 Anesakikaigan Ichihara City, Chiba Prefecture, 299-0193 |

|---|