Technology & Engineering Center

About Technology & Engineering Center

Technology & Engineering Center is a group of specialized engineers involved in the development, design, construction, operation, quality and maintenance of manufacturing processes.

We contribute to the supply of petroleum and chemical products by ensuring the safe and stable operation and strengthening the competitiveness of Refineries/Complexes overseas. We also work to quickly realize provide for society by utilizing the technology we have cultivated through these businesses in cooperation with internal and external parties.

Main initiatives/research contents - 01

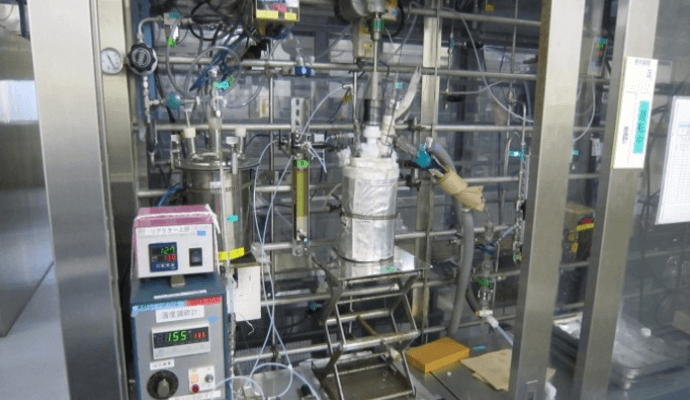

Experiments and analysis for manufacturing process development and optimization

We are working on the development and mass production of new materials used in biofuels, EVs, etc. The manufacturing process of the products is an important factor that determines the quality, cost, productivity, supply stability, etc. At the Technology & Engineering Center we create various experimental equipment and collect and analyze data for designing and optimizing the manufacturing process. In order to scale up from flask-sized experimental data to equipment with an annual production capacity of tens of thousands of tons, precise experiments and analysis are required.

Main initiatives/research contents - 02

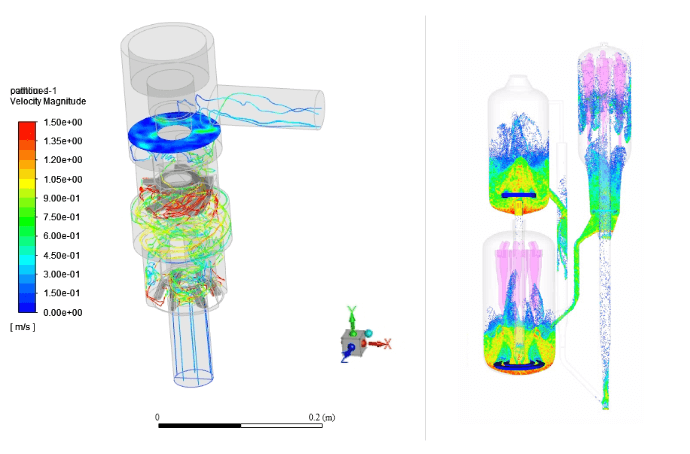

Analysis and design of manufacturing processes using computational fluid simulation

In the development of processes for manufacturing new functional materials, the development and design of reactors is extremely important because it affects quality, cost, and product yield. In order to design higher performance reactors, Technology & Engineering Center experimentally collects chemical reaction data, evaluates flow patterns using cold models, and finally performs optimal reactor design using computational fluid simulation. In particular, since experiments cannot be performed on the scale of actual equipment, it is necessary to accurately predict reactor performance using virtual simulations and understand the optimal conditions for actual operation. The figure shows the analysis results of a stirred tank reactor and a fluid catalytic cracking reactor.

Main initiatives/research contents - 03

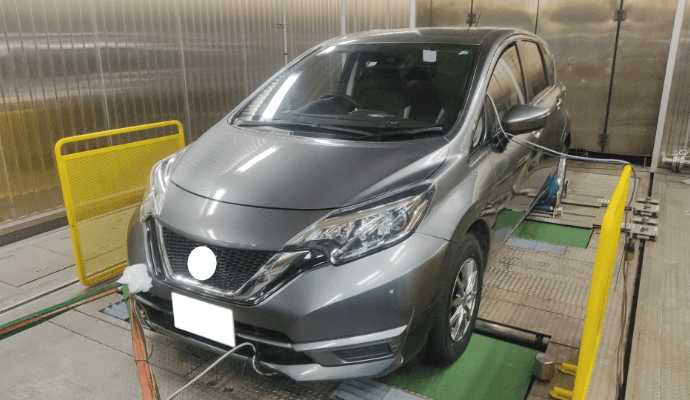

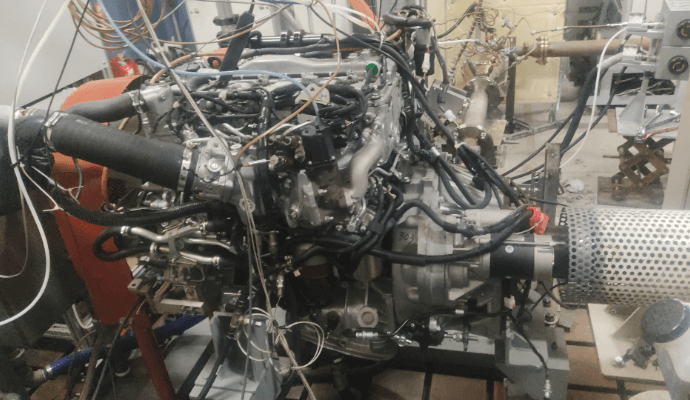

Fuel quality design using actual vehicles and engines

We carry out research and research for the rational use of petroleum products, quality design that responds to future changes, technology accumulation research regarding the safety of petroleum products, and quality design that takes safety into consideration. Gasoline and diesel oil are used as fuel for passenger cars, trucks, buses, etc., so we have equipment such as chassis dynamo equipment and engine bench equipment that allow us to evaluate actual vehicles and engines. Chassis dynamo equipment uses actual vehicles to evaluate exhaust emissions and drivability under various temperatures and operating conditions to design fuels suitable for each region and season in Japan. In addition, our engine bench equipment performs various evaluations of individual engines, mainly on exhaust gas and combustion conditions, which is used to design the quality of automotive fuels.

access

| Address | 34th floor, WBG Malibu East, 2-6-1 Nakase, Mihama-ku, Chiba-shi, Chiba 261-7134 |

|---|