CIGS Solar Cells for Space Applications

What is CIGS?

CIGS solar cells are solar cells that use compound semiconductor materials primarily composed of Cu (copper), In (indium), Ga (gallium), and Se (selenium). CIGS has characteristics that is the extremely high radiation resistance in the material itself. And CIGS solar cells are formed as a very thin film on a substrate, making them extremely lightweight.

CIGS Solar Cells to Support Space Development

Idemitsu Kosan's CIGS solar cells exhibit excellent performance even in harsh space environments thanks to their exceptional radiation tolerance. In addition, their lightweight design helps reduce launch costs. Our CIGS solar cells will support the future of space development from an energy perspective.

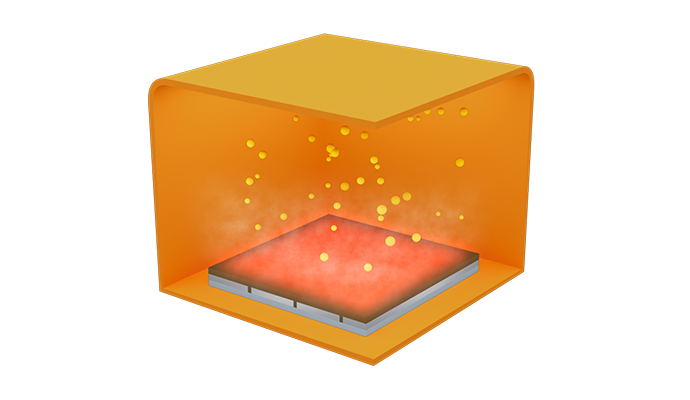

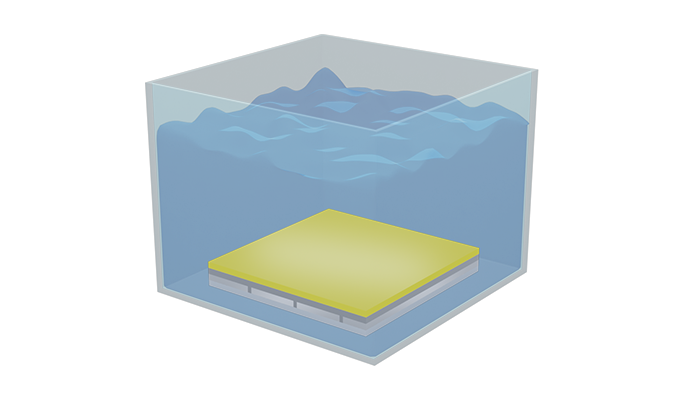

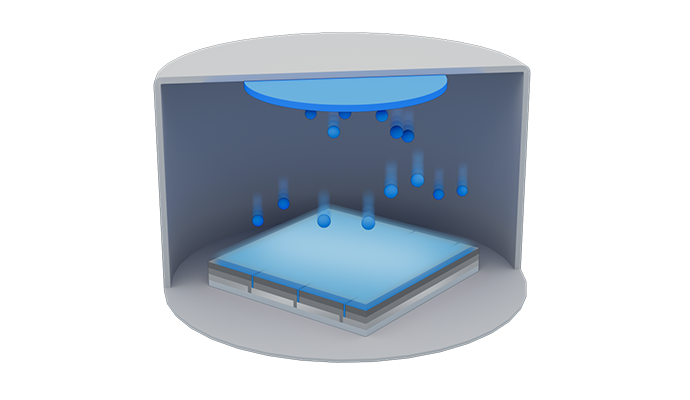

Extremely High Radiation Resistance

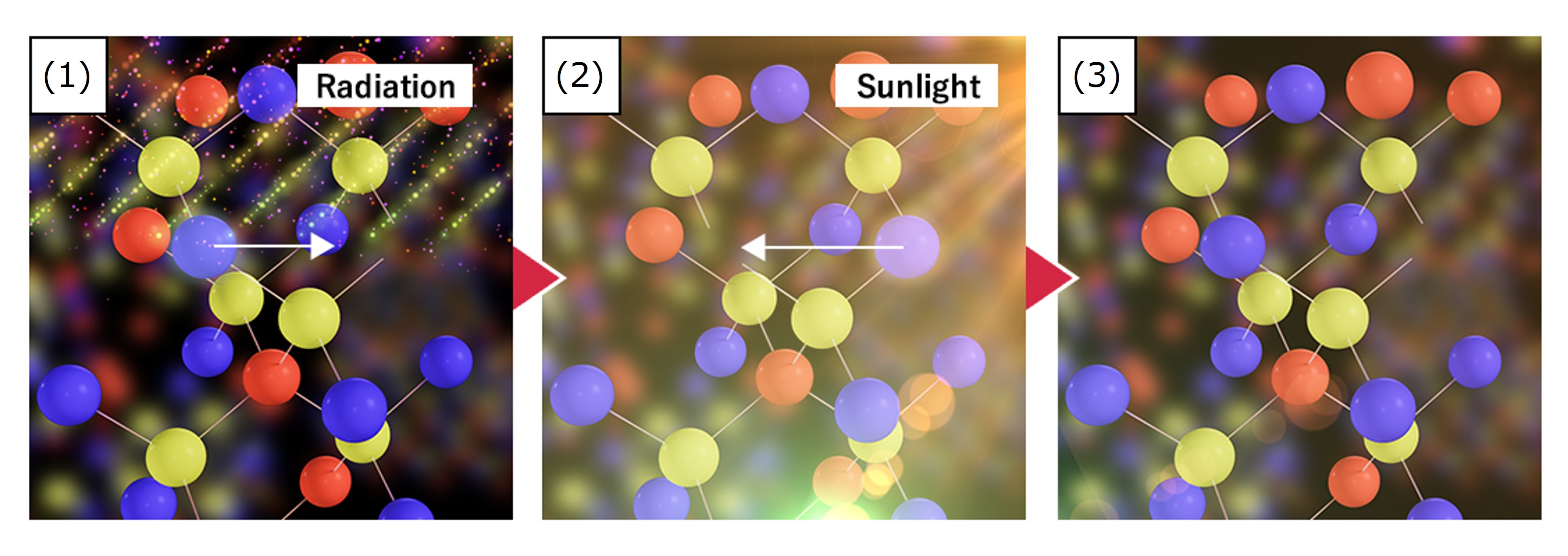

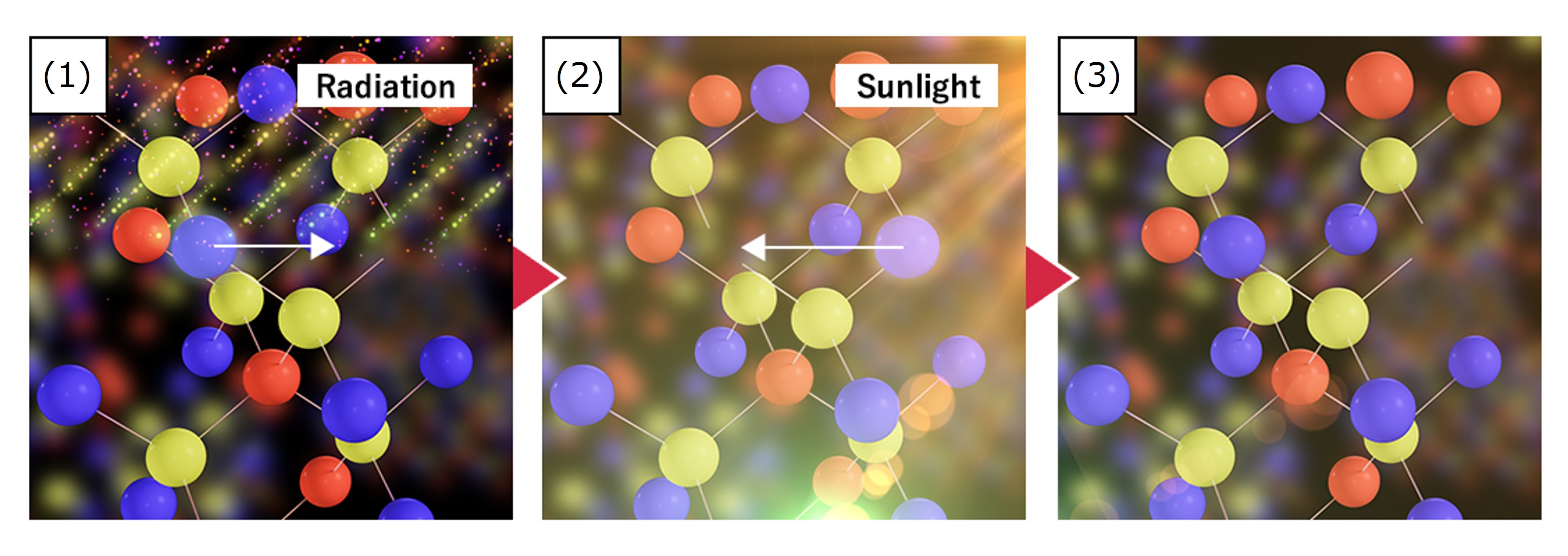

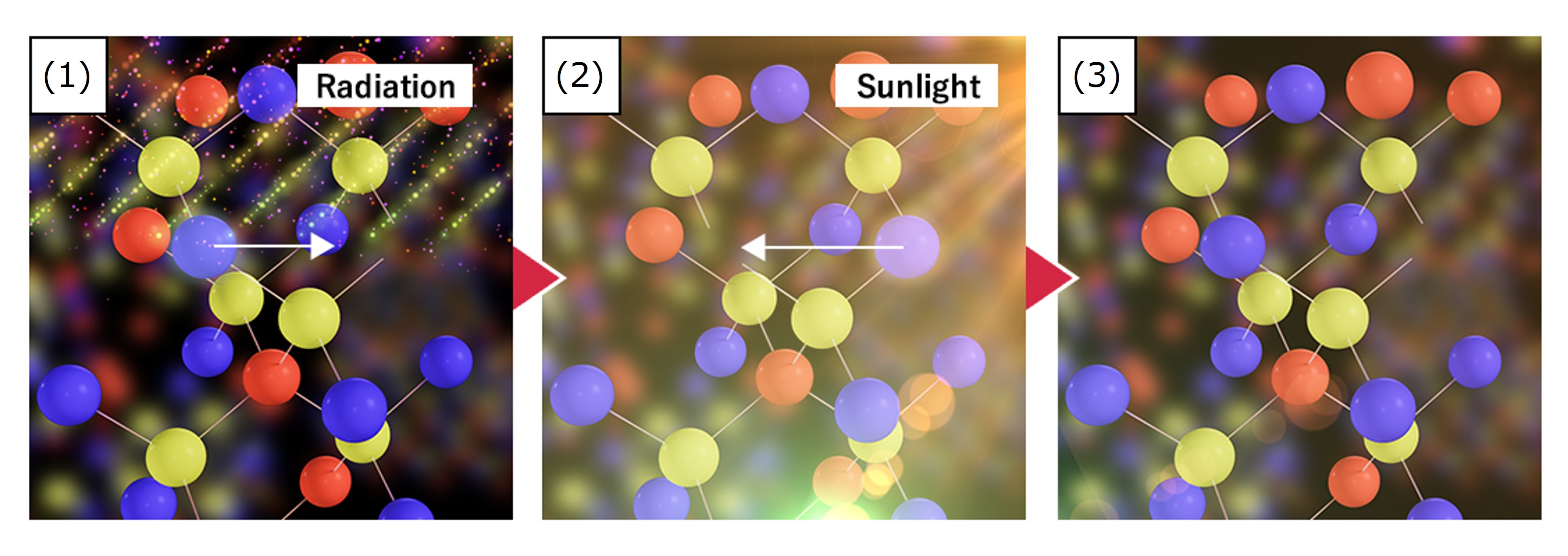

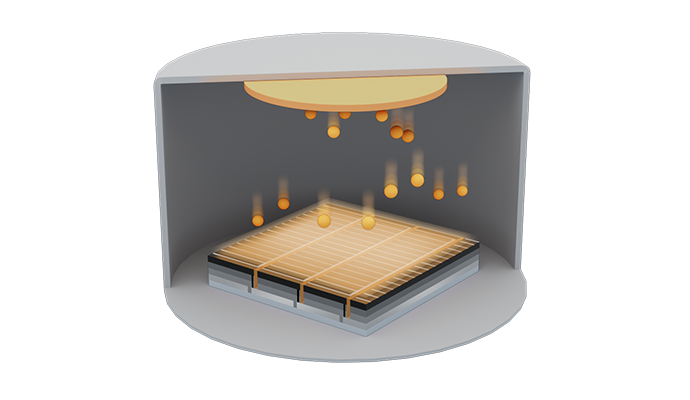

"Self-healing" with light exposure minimizes conversion efficiency degradation from radiation.

As a result, their power conversion efficiency experiences almost no degradation due to radiation. This remarkable durability has proven through tests that our CIGS solar cells maintained stable power output for nine years in low Earth orbit (approximately 700 km altitude) — even without a coverglass.*1

Sources:

*1 S.Kawakita et al., Trans. JSASS Space Tech. Japan Vol. 7, No ists26, pp. Ph_49-53 (2009), S. Kawakita et al., MRS Online Proceedings Library 1792, 479 (2015).

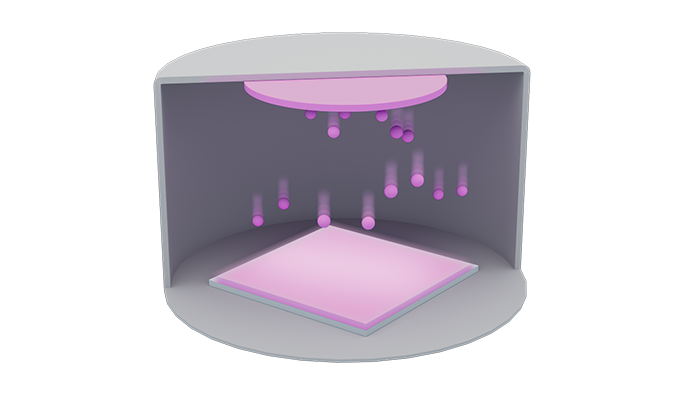

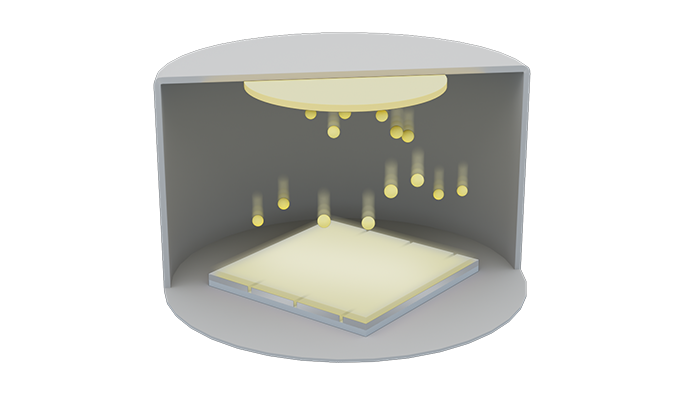

Schematic diagram of the CIGS crystal structure. Each colored sphere represents an atom that consists of the CIGS crystal. (1) Radiation in space causes local defects (atoms become displaced). (2)-(3) The structure is healed by sunlight (atoms return to their original positions).

Schematic diagram of the CIGS crystal structure. Each colored sphere represents an atom that consists of the CIGS crystal. (1) Radiation in space causes local defects (atoms become displaced). (2)-(3) The structure is healed by sunlight (atoms return to their original positions).

Schematic diagram of the CIGS crystal structure. Each colored sphere represents an atom that consists of the CIGS crystal. (1) Radiation in space causes local defects (atoms become displaced). (2)-(3) The structure is healed by sunlight (atoms return to their original positions).

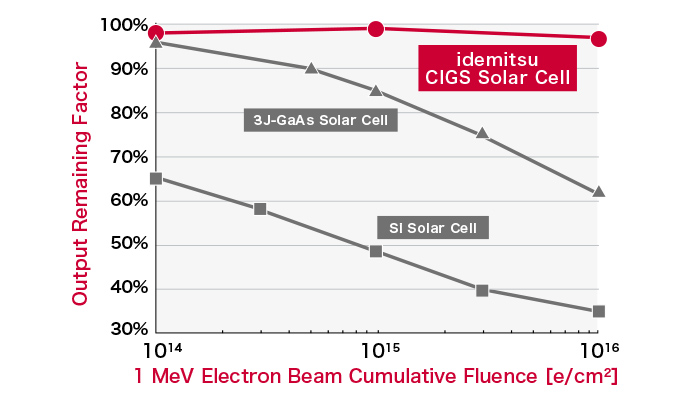

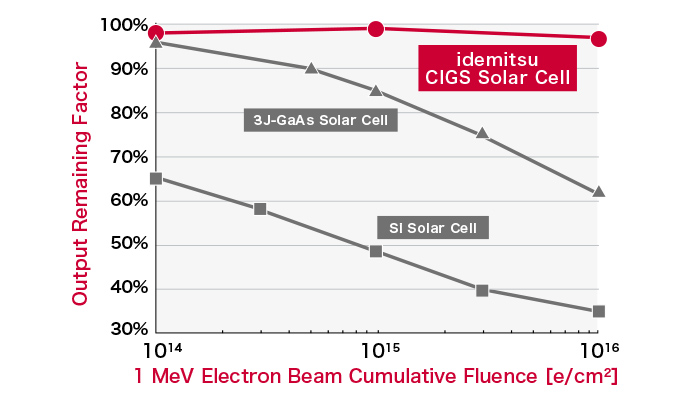

Comparison of radiation durability

Silicon (Si) or triple-junction gallium arsenide (3J-GaAs), which are commonly used in space applications, suffer power loss due to radiation compared with their beginning-of-life output. In contrast, our CIGS solar cells maintain its output for much longer periods thanks to the self-healing ability mentioned above.

Changes in output remaining factors by radiation dose (1 MeV electron beam exposure)

Changes in output remaining factors by radiation dose (1 MeV electron beam exposure)

Changes in output remaining factors by radiation dose (1 MeV electron beam exposure)

Reference:

1) 3J-GaAs Solar Cell : SolAero ZTJ SPACE SOLAR CELL Datasheet

2) SI Solar Cell : Yamaguchi M, Lee KH, Araki K, et al., the 46th Photovoltaic Specialists Conference (PVSC). IEEE; 2019, pp. 2377-2380.

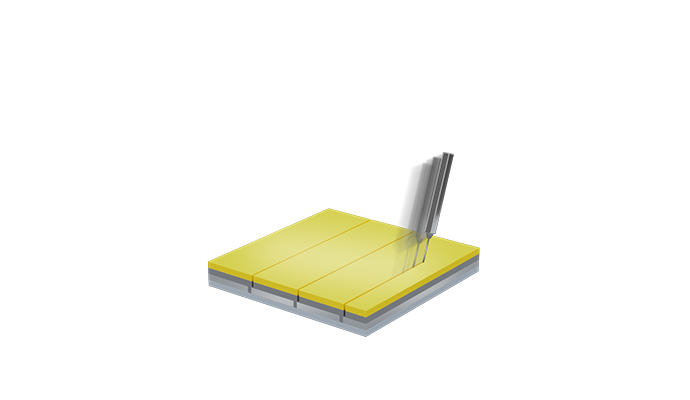

Advantages in Space Applications by Thin Film Lightweighting

Reduce manufacturing and launch costs through high radiation tolerance

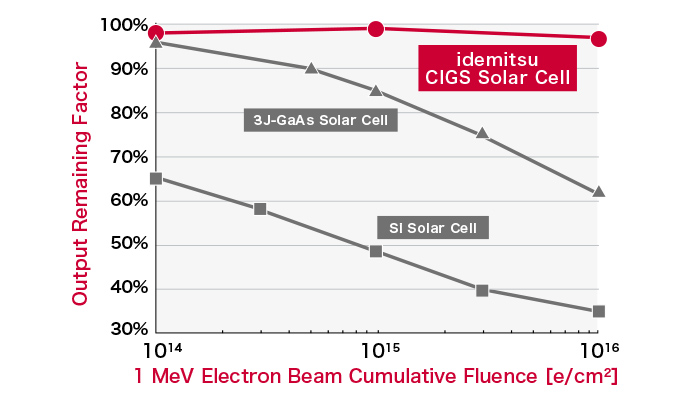

Thanks to their strong radiation resistance, our CIGS solar cells do not require a protective coverglass. Eliminating this layer, which is essential in conventional designs, enables thinner and lighter solar cells. Furthermore, our proprietary thin-film manufacturing process allows for an even thinner CIGS layer, as well as customizable size, current, and voltage specifications.

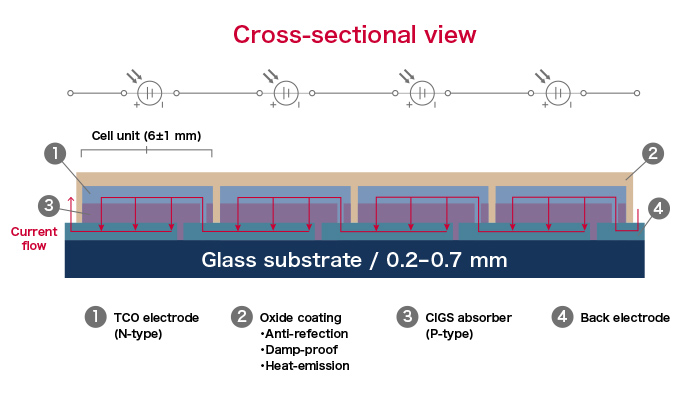

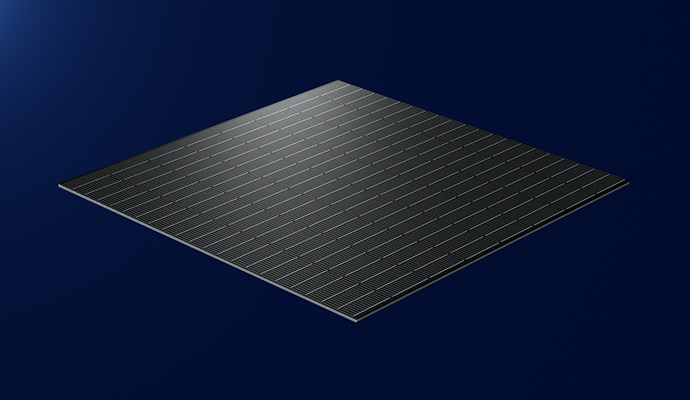

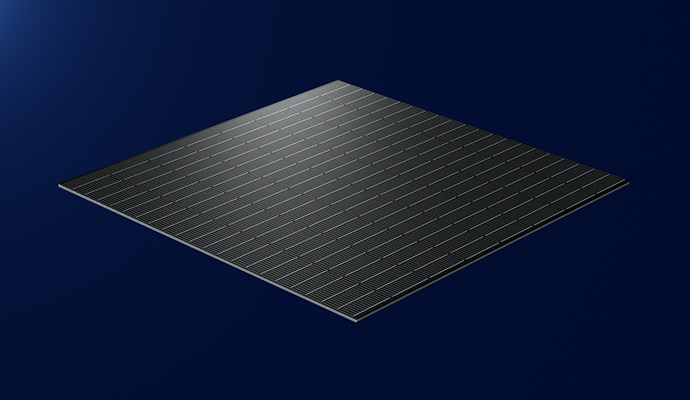

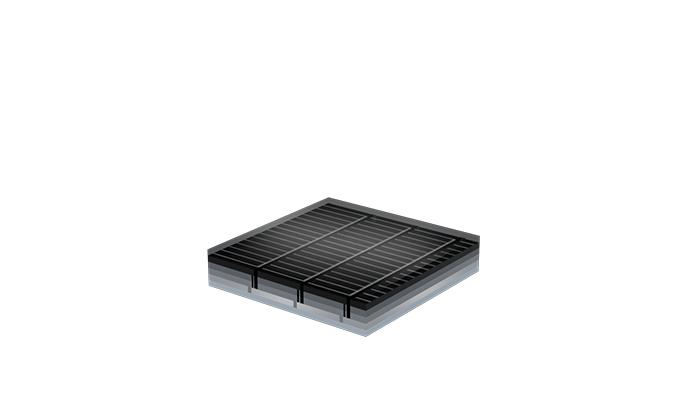

Scalable with Thin-Film Technology

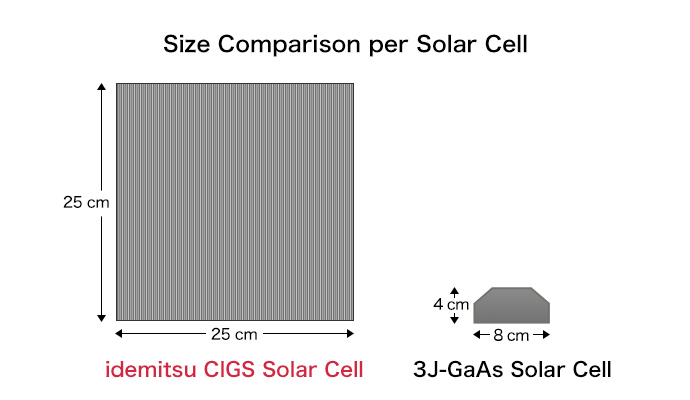

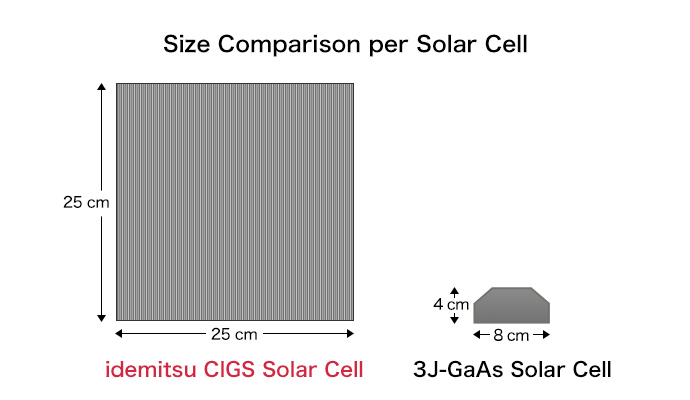

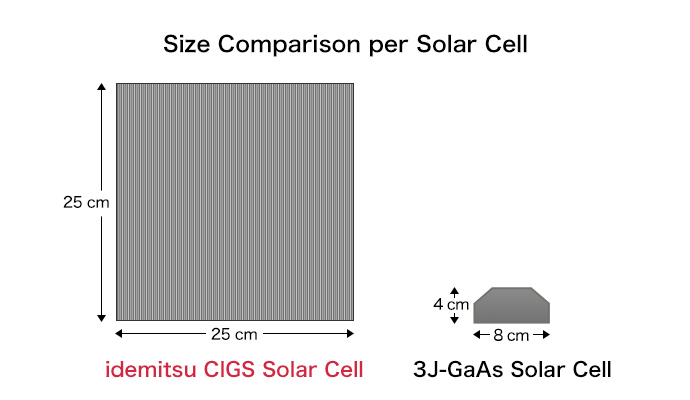

By using a thin-film process on a large glass substrate, we have achieved enlargement of solar cells (up to 25 cm x 25 cm size*2), which is difficult to achieve with conventional technologies. Larger cells improve the packing factor, enhancing the overall power generation of the panel.

In addition, by using fewer cells per panel reduces the number of interconnects*3, improving both manufacturing and reliability by minimizing potential connection failures.

*2 As of October 2025

*3 Interconnect: The part that electrically connects the solar cells.

Applications for Various Space Uses

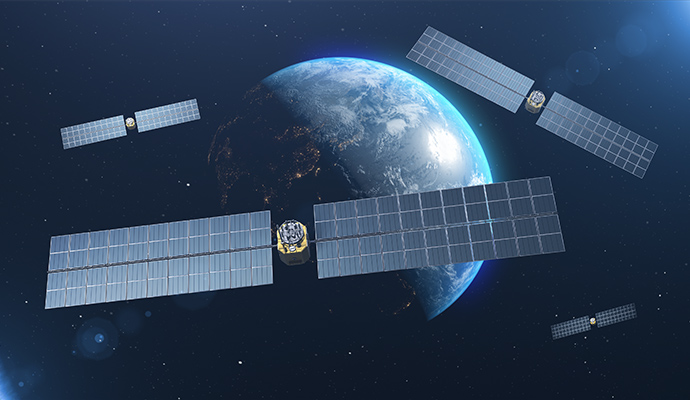

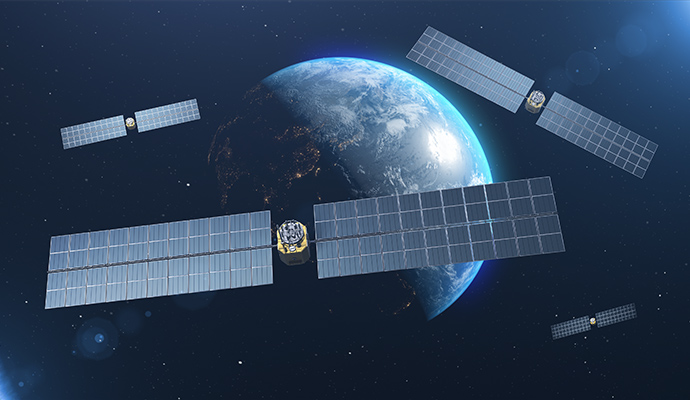

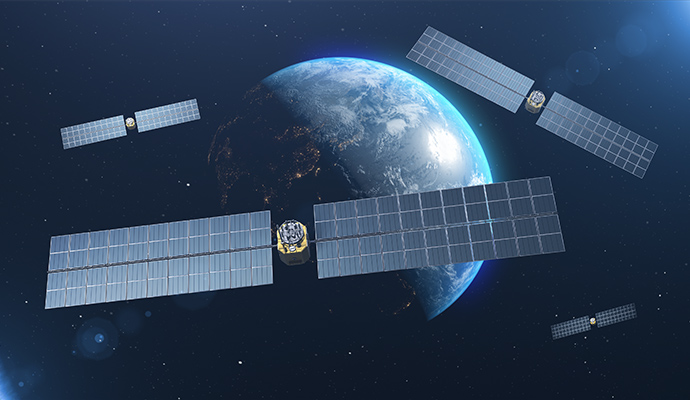

From supplying power to satellites, to power sources for lunar exploration, and space solar power systems

Since the power required for low Earth orbit constellation*4 satellites are growing because of the increased communications traffic and AI image analysis, more and more stable power supply will be required in the future. Furthermore, in medium Earth orbit (altitudes of 2,000 km - 36,000 km), where radiation is much stronger, the high radiation tolerance of our CIGS solar cells can contribute to the long-term operation of satellites. In addition, when constructing a large space structure, its components must be transported by a rocket in separate segments and assembled in space. Our lightweight and thin CIGS solar cells can reduce the transportation costs.

The characteristics of our CIGS solar cells, which are lightweight, high power, and exhibit extremely high radiation tolerance, make them suitable for various space applications, and are expected to be used as an energy source to support future space development, such as a power source for lunar exploration or space solar power systems.

*4 A system in which numerous small satellites operate in a ncoordinated etwork at altitudes of a few hundred km to 2,000 km, delivering global communication and Earth observation capabilities

Stable power supply to low Earth orbit and medium Earth orbit satellites

Stable power supply to low Earth orbit and medium Earth orbit satellites

Stable power supply to low Earth orbit and medium Earth orbit satellites

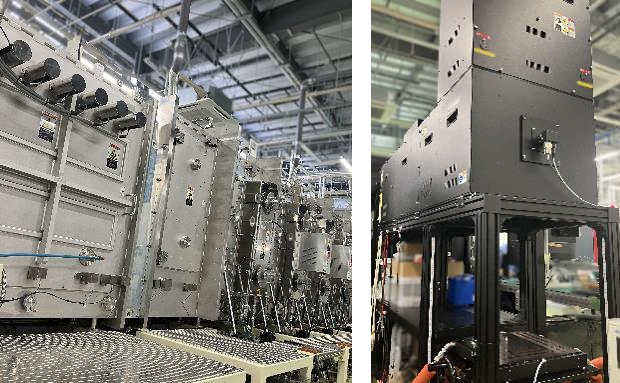

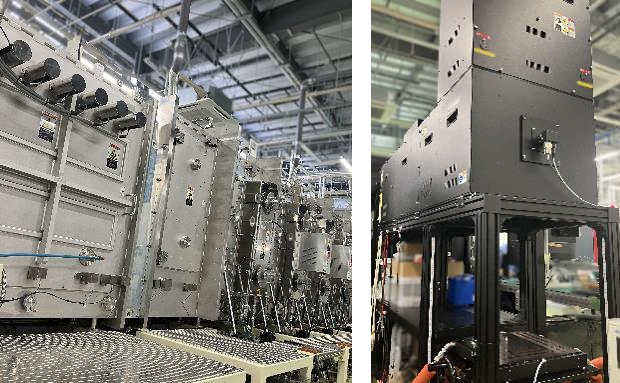

From Terrestrial Achievements to Space Innovation

More than 30 years of research and development in CIGS solar cells, along with a proven track record in more than 6GW mass production

Idemitsu has engaged in R&D on CIGS solar cells for more than 30 years, long before establishing our wholly owned subsidiary, Solar Frontier.

In terrestrial solar power generation business, we have achieved the world's highest conversion efficiency of 23.35% (AM1.5*5) and cumulative shipments of 6 GW of solar modules in 2019 and 2020, respectively.

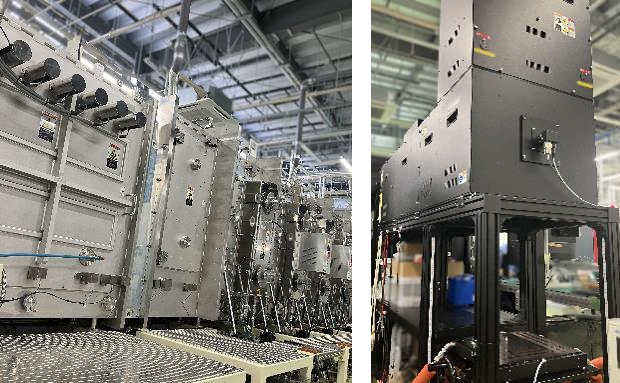

Our R&D facilities, covering more than 1,000 m2, are equipped not only with full-scale manufacturing systems for integrated solar cells but also with advanced testing and analysis equipment dedicated to space applications.

*5 Air Mass 1.5, a standard solar condition used to evaluate terrestrial solar cells performance.

Advanced Technology Research Laboratories

Solar cell R&D facilities (left: sputter deposition equipment, right: solar cell characterization equipment)

Advanced Technology Research Laboratories

Solar cell R&D facilities (left: sputter deposition equipment, right: solar cell characterization equipment)

Advanced Technology Research Laboratories

Solar cell R&D facilities (left: sputter deposition equipment, right: solar cell characterization equipment)

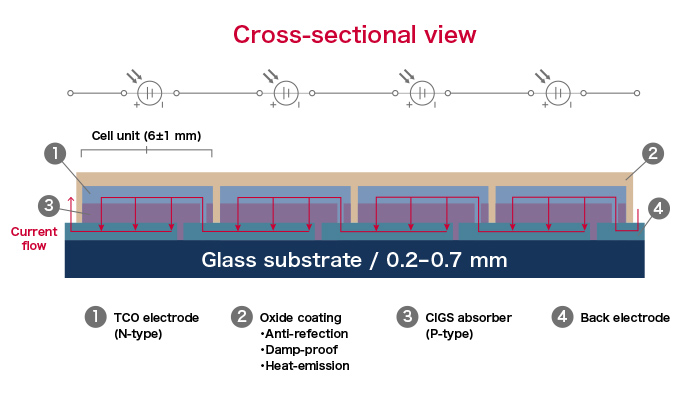

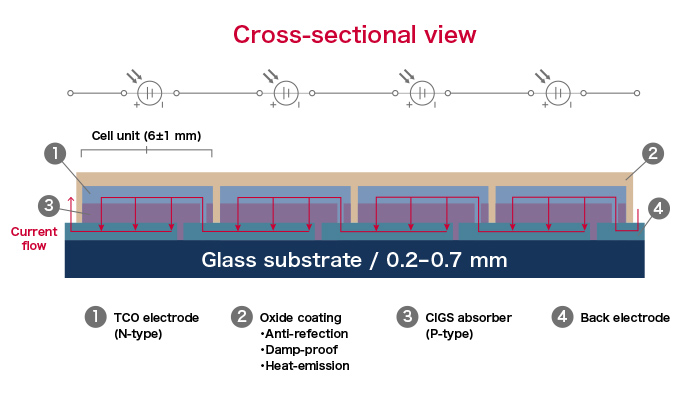

idemitsu CIGS Solar Cell Manufacturing Process

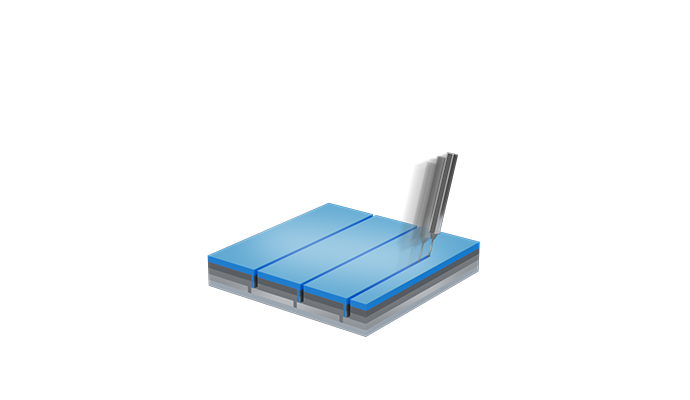

1: Deposition of the backside electrode layer

Clean the glass substrate.

A thin metal film less than one micrometer is deposited on a glass substrate.

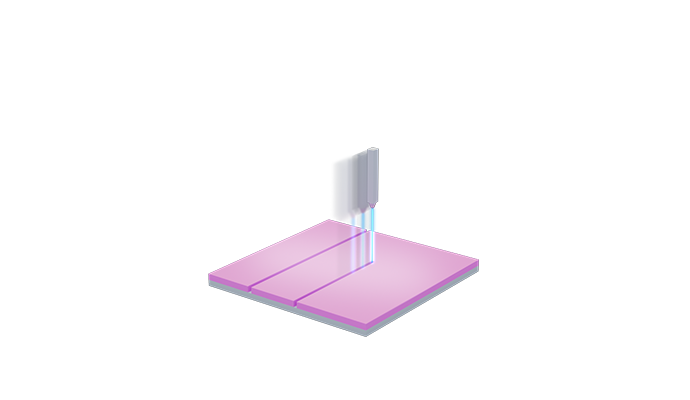

2: Formation of “Patterning 1”

The metal backside electrode layer is cut with a laser into circuits.

Voltages etc. can be customized depending on the number of the circuits.

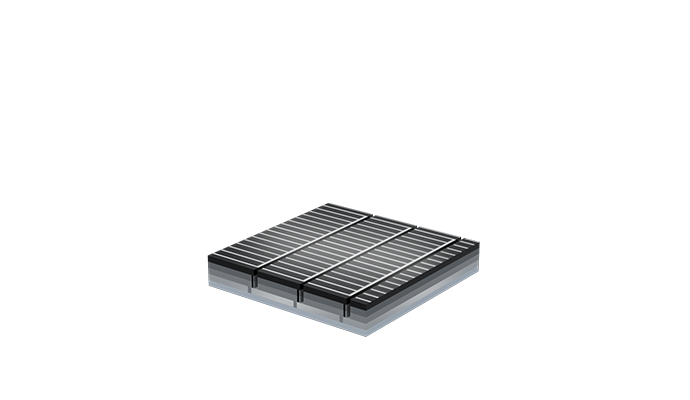

3: Deposition of precursor material

Precursor is deposited on the metal backside electrode that forms “Pattern 1”.

4: Formation of a light-absorbing layer

The substrate with the precursor is baked in a special gas to form the light-absorbing CIGS layer.

5: Deposition of a buffer layer

A buffer layer is formed by immersing the substrate in a special solution.

6: Patterning 2

Mechanical scribe separates the light-absorbing layer and the buffer layer.

7: Deposition of a surface electrode layer

A surface electrode layer is deposited.

8: Patterning 3

Mechanical scribe separates the light-absorbing layer, the buffer layer, and the surface electrode layer.

9: Grid electrode formation

A grid electrode is formed on top of the surface electrode layer.

10: Deposition of an anti-reflective layer

An anti-reflective layer is deposited on top of the surface electrode layer and the grid electrode.

11: idemitsu CIGS solar cells are manufactured

The History of CIGS Solar Cells

and Space Initiatives

in Idemitsu Group

|

|

|

|

|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Our CIGS solar cell (25 cm x 25 cm size)

Our CIGS solar cell (25 cm x 25 cm size)

Our CIGS solar cell (25 cm x 25 cm size)

Related information

Ready to Power Your Mission? Contact Us Today!

Have questions or need more information? Reach out via the link, and let’s take your space project to new limits with Idemitsu CIGS solar cells!