Glass fiber reinforced, UL94 HB grade

| Grade classification | glass fiber content | grade name | Application |

|---|---|---|---|

| Glass fiber reinforced, UL94 HB grade | GF15% | C122 | electronic components |

| GF30% | C132 | Home appliances, electronic parts, food | |

| GF40% | C142 | ||

| GF15% | S124 | food | |

| GF30% | S135 | food, home appliances | |

| GF17% | S123 | Automotive electrical parts, electronic parts | |

| GF30% | S131 | Electronic parts, electrical machinery, automobile electrical parts | |

| GF30% | S136 | Automotive electrical parts, electrical machinery | |

| GF20% | WA 210 | Automotive electrical parts, industrial products, home appliances, electronic parts, food (EU), drinking water (NA) | |

| GF30% | WA 212 | ||

| GF40% | WA 214LG | ||

| GF30% | WA552 |

-

The uses described in this document do not guarantee the results of applying this product to those uses.

-

When using the product for the purposes introduced in this document, please be careful about infringing on industrial property rights (patent rights, utility model rights, design rights, trademark rights). (Our company is not responsible for infringement of industrial property rights.)

-

It cannot be used for medical equipment or medical products.

-

If the product is to be used in food utensils or packaging, please have our sales representative thoroughly confirm the compatibility of the applicable grade with relevant laws and regulations (Food Sanitation Law, etc.) before signing the delivery specifications. I will do it.

-

It is the customer's responsibility to check the compliance of products processed by the customer with various laws and regulations using our products as raw materials.

-

Please note that the contents of this document are subject to change without notice due to improvements.

C122, C132, C142

Application example: Vacuum cleaner motor fan guide

Standard grade with glass fiber reinforcement and flame retardant level UL 94HB (1/32").

C122 is reinforced with 15% glass fiber, C132 is reinforced with 30% glass fiber, and C142 is reinforced with 40% glass fiber, and can be used depending on the required rigidity, load capacity, specific gravity, etc.

It has a low specific gravity and is second only to S105 in electrical properties such as high frequency characteristics and tracking resistance, and hydrolysis resistance. In addition, it has a good balance of mechanical strength, formability, and other properties, and can be used as a standard in electrical/electronic parts and a wide range of other application fields.

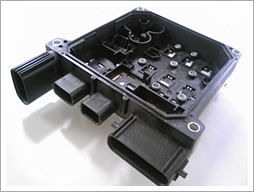

S131

Application example: Electronic Control Unit

30% glass fiber reinforced and registered to UL94HB. It is widely used in automotive electrical parts.

Zarec's UL746B certified temperature (℃)

| Grade | Electrical | mechanical | ||

|---|---|---|---|---|

| V-0 thickness [mm] | Impact | No impact | ||

| S131 | H.B. | 130 | 120 | 130 |

S135, S124

Can be used for food contact applications.

S136

Can be used for automotive electrical parts. Low gas specification.

Physical properties table

July 8, 2022

| Test items | Measurement method | (Measurement condition) | Unit | C122 | C132 | C142 |

|---|---|---|---|---|---|---|

| ISO material display |

>PS-ST- GF15< |

>PS-ST- GF30< |

>PS-ST- GF40< |

|||

| physical properties | ||||||

| density | ISO 1183 | g/cm3 | 1.11 | 1.25 | 1.36 | |

| glass fiber content | wt% | 15 | 30 | 40 | ||

| Water absorption rate | ISO 62 | 24h 50%RH | % | 0.01 | 0.01 | 0.02 |

| Mechanical properties | ||||||

| Tensile breaking strength | ISO 527 | MPa | 75 | 120 | 130 | |

| tensile modulus | MPa | 5,400 | 9,700 | 12,600 | ||

| Tensile elongation at break | % | 2.7 | 2.1 | 1.5 | ||

| bending strength | ISO 178 | MPa | 120 | 185 | 195 | |

| bending modulus | MPa | 5,000 | 9,200 | 12,400 | ||

| Izod impact strength | ISO 180 | With notch at 23℃ | kJ/ m2 | 11 | 13 | 10 |

| No notch at 23℃ | 30 | 36 | 33 | |||

| Charpy impact strength | ISO 179 | With notch at 23℃ | kJ/ m2 | 11 | 13 | 9 |

| No notch at 23℃ | 35 | 43 | 27 | |||

| thermal properties | ||||||

| Load deflection temperature | ISO 75A | 1.8MPa | ℃ | 140 | 240 | 250 |

| ISO 75B | 0.45MPa | 260 | 265 | 270 | ||

| Linear expansion coefficient | TMA |

flow direction (MD), -30~30℃ |

x10-6 mm/mm/℃ | 30 | 18 | 15 |

|

Transverse direction (TD), -30~30℃ |

81 | 39 | 40 | |||

| Molding shrinkage rate | Idemitsu method | Flow direction (MD) | % | 0.4 - 0.7 | 0.1 - 0.4 | 0.1 - 0.4 |

| Right angle direction (TD) | 0.5 - 0.8 | 0.5 - 0.8 | 0.5 - 0.8 | |||

| Flammability/UL related standards, etc. | ||||||

| Combustion quality | UL94 | HB minimum thickness | mm | 0.8 | 0.8 | 0.8 |

| V-0 minimum thickness | - | - | - | |||

| 5VA minimum thickness | - | - | - | |||

|

Temperature index RTI Elec Imp Str |

UL 746B | ℃ | 50 | 50 | 50 | |

| 50 | 50 | 50 | ||||

| 50 | 50 | 50 | ||||

| Tracking resistance (CTI) | IEC 60112, Solution A | PLC level |

0 equivalent |

1 equivalent |

1 equivalent |

|

| High voltage arc tracking rate (HVTR) | UL 746A | PLC level | - | - | - | |

| Hot wire ignitability (HWI) | UL 746A | @3.0mm | PLC level | - | - | - |

| @1.5mm | - | - | - | |||

| @0.75mm | - | - | - | |||

| High current arc ignitability (HAI) | UL 746A | @3.0mm | PLC level | - | - | - |

| @1.5mm | - | - | - | |||

| @0.75mm | - | - | - | |||

| arc resistance | ASTM D495 | PLC level |

6 equivalent |

6 equivalent |

6 equivalent |

|

| Electrical characteristics | ||||||

| Volume resistivity | IEC 60093 | Ohm-cm | >1E+16 | >1E+16 | >1E+16 | |

| Withstand voltage (dielectric breakdown strength) | ASTM D149 | kV/mm | 45 | 45 | 45 | |

| relative dielectric constant | IEC 60250 | 1MHz | 2.8 | 2.9 | 3 | |

| Dissipation tangent | IEC 60250 | 1MHz | <0.001 | <0.001 | <0.001 | |

| Standard molding conditions | ||||||

| cylinder temperature | ℃ | 280 - 310 | 280 - 310 | 280 - 310 | ||

| mold temperature | ℃ | 130-155 | 130-155 | 130-155 | ||

| Drying conditions | 120℃, 3-5 hours | 120℃, 3-5 hours | 120℃, 3-5 hours | |||

| Test items | Measurement method | (Measurement condition) | Unit | S124 | S135 | S123 |

|---|---|---|---|---|---|---|

| ISO material display |

>PS-ST- GF15< |

>PS-ST- GF30< |

>PS-ST- GF17< |

|||

| physical properties | ||||||

| density | ISO 1183 | g/cm3 | 1.13 | 1.26 | 1.14 | |

| glass fiber content | wt% | 15 | 30 | 17 | ||

| Water absorption rate | ISO 62 | 24h 50%RH | % | 0.01 | 0.01 | 0.01 |

| Mechanical properties | ||||||

| Tensile breaking strength | ISO 527 | MPa | 85 | 125 | 85 | |

| tensile modulus | MPa | 6,000 | 9,700 | 6,000 | ||

| Tensile elongation at break | % | 2.5 | 2 | 2.5 | ||

| bending strength | ISO 178 | MPa | 130 | 200 | 130 | |

| bending modulus | MPa | 6,000 | 9,800 | 6,000 | ||

| Izod impact strength | ISO 180 | With notch at 23℃ | kJ/ m2 | 9 | 11 | 9 |

| No notch at 23℃ | 28 | 32 | 28 | |||

| Charpy impact strength | ISO 179 | With notch at 23℃ | kJ/ m2 | 9 | 12 | 9 |

| No notch at 23℃ | 34 | 40 | 34 | |||

| thermal properties | ||||||

| Load deflection temperature | ISO 75A | 1.8MPa | ℃ | 210 | 250 | 188 |

| ISO 75B | 0.45MPa | 260 | 270 | 260 | ||

| Linear expansion coefficient | TMA |

flow direction (MD), -30~30℃ |

x10-6 mm/mm/℃ | - | 18 | 22 |

|

Transverse direction (TD), -30~30℃ |

- | 43 | 75 | |||

| Molding shrinkage rate | Idemitsu method | Flow direction (MD) | % | 0.4 - 0.7 | 0.1 - 0.4 | 0.5 - 0.7 |

| Right angle direction (TD) | 0.6 - 0.9 | 0.5 - 0.8 | 0.7 - 0.9 | |||

| Flammability/UL related standards, etc. | ||||||

| Combustion quality | UL94 | HB minimum thickness | mm | - | 0.8 | 1.5 |

| V-0 minimum thickness | - | - | - | |||

| 5VA minimum thickness | - | - | - | |||

|

Temperature index RTI Elec Imp Str |

UL 746B | ℃ | - | 50 | - | |

| - | 50 | - | ||||

| - | 50 | - | ||||

| Tracking resistance (CTI) | IEC 60112, Solution A | PLC level | - |

1 equivalent |

- | |

| High voltage arc tracking rate (HVTR) | UL 746A | PLC level | - | - | - | |

| Hot wire ignitability (HWI) | UL 746A | @3.0mm | PLC level | - | - | - |

| @1.5mm | - | - | - | |||

| @0.75mm | - | - | - | |||

| High current arc ignitability (HAI) | UL 746A | @3.0mm | PLC level | - | - | - |

| @1.5mm | - | - | - | |||

| @0.75mm | - | - | - | |||

| arc resistance | ASTM D495 | PLC level | - | - | - | |

| Electrical characteristics | ||||||

| Volume resistivity | IEC 60093 | Ohm-cm | - | >1E+16 | >1E+16 | |

| Withstand voltage (dielectric breakdown strength) | ASTM D149 | kV/mm | - | 45 | - | |

| relative dielectric constant | IEC 60250 | 1MHz | - | 2.9 | 2.8 | |

| Dissipation tangent | IEC 60250 | 1MHz | - | <0.001 | 0.0006 | |

| Standard molding conditions | ||||||

| cylinder temperature | ℃ | 280 - 310 | 280 - 310 | 280 - 310 | ||

| mold temperature | ℃ | 130-155 | 130-155 | 130-155 | ||

| Drying conditions | 120℃, 3-5 hours | 120℃, 3-5 hours | 120℃, 3-5 hours | |||

| Test items | Measurement method | (Measurement condition) | Unit | S131 | S136 |

|---|---|---|---|---|---|

| ISO material display |

>PS-ST-GF30 < |

>PS-ST-GF30 < |

|||

| physical properties | |||||

| density | ISO 1183 | g/cm3 | 1.25 | 1.25 | |

| glass fiber content | wt% | 30 | 30 | ||

| Water absorption rate | ISO 62 | 24h 50%RH | % | 0.01 | 0.01 |

| Mechanical properties | |||||

| Tensile breaking strength | ISO 527 | MPa | 120 | 120 | |

| tensile modulus | MPa | 9,700 | 9,700 | ||

| Tensile elongation at break | % | 2.1 | 2.1 | ||

| bending strength | ISO 178 | MPa | 190 | 190 | |

| bending modulus | MPa | 9,300 | 9,300 | ||

| Izod impact strength | ISO 180 | With notch at 23℃ | kJ/ m2 | 12 | 12 |

| No notch at 23℃ | 39 | 39 | |||

| Charpy impact strength | ISO 179 | With notch at 23℃ | kJ/ m2 | 12 | 12 |

| No notch at 23℃ | 44 | 44 | |||

| thermal properties | |||||

| Load deflection temperature | ISO 75A | 1.8MPa | ℃ | 245 | 245 |

| ISO 75B | 0.45MPa | 265 | 265 | ||

| Linear expansion coefficient | TMA |

flow direction (MD), -30~30℃ |

x10-6 mm/mm/℃ | 19 | 19 |

|

Transverse direction (TD), -30~30℃ |

43 | 43 | |||

| Molding shrinkage rate | Idemitsu method | Flow direction (MD) | % | 0.1 - 0.4 | 0.1 - 0.4 |

| Right angle direction (TD) | 0.3 - 0.8 | 0.3 - 0.8 | |||

| Flammability/UL related standards, etc. | |||||

| Combustion quality | UL94 | HB minimum thickness | mm | 0.75 | 1.5 |

| V-0 minimum thickness | - | - | |||

| 5VA minimum thickness | - | - | |||

|

Temperature index RTI Elec Imp Str |

UL 746B | ℃ | 130 | - | |

| 120 | - | ||||

| 130 | - | ||||

| Tracking resistance (CTI) | IEC 60112, Solution A | PLC level | 1 equivalent | 1 equivalent | |

| High voltage arc tracking rate (HVTR) | UL 746A | PLC level | - | - | |

| Hot wire ignitability (HWI) | UL 746A | @3.0mm | PLC level | - | - |

| @1.5mm | - | - | |||

| @0.75mm | - | - | |||

| High current arc ignitability (HAI) | UL 746A | @3.0mm | PLC level | - | - |

| @1.5mm | - | - | |||

| @0.75mm | - | - | |||

| arc resistance | ASTM D495 | PLC level | - | - | |

| Electrical characteristics | |||||

| Volume resistivity | IEC 60093 | Ohm-cm | >1E+16 | >1E+16 | |

| Withstand voltage (dielectric breakdown strength) | ASTM D149 | kV/mm | 48 | 48 | |

| relative dielectric constant | IEC 60250 | 1MHz | 2.9 | 2.9 | |

| Dissipation tangent | IEC 60250 | 1MHz | <0.001 | <0.001 | |

| Standard molding conditions | |||||

| cylinder temperature | ℃ | 280 - 310 | 280 - 310 | ||

| mold temperature | ℃ | 130-155 | 130-155 | ||

| Drying conditions | 120℃, 3-5 hours | 120℃, 3-5 hours | |||

-

The data presented in this document are representative of measurements obtained under specific conditions.

-

The uses described in this document do not guarantee the results of applying this product to those uses.

-

When using the product for the purposes introduced in this document, please be careful about infringing on industrial property rights (patent rights, utility model rights, design rights, trademark rights). (Our company is not responsible for infringement of industrial property rights.)

-

It cannot be used for medical equipment or medical products.

-

If the product is to be used for food utensils or packaging, please have our sales representative thoroughly confirm the compatibility of the applicable grade with relevant laws and regulations (Food Sanitation Law, etc.) in advance and sign the delivery specifications. I will do it.

-

It is the customer's responsibility to check the compliance of products processed by the customer with various laws and regulations using our products as raw materials.

-

Please note that the contents of this document are subject to change without notice due to improvements.

-

The flammability described in this document is an evaluation based on small-scale tests, and cannot be directly applied to the evaluation of danger in an actual fire.