Hokkaido Refinery | Quality Initiatives

Since it began operations, this Refinery has consistently maintained its "consumer-oriented" management philosophy, promoting quality control activities in line with the idea of directly connecting with customers and steadily supplying appropriate products that meet their needs. In 1974, it was certified as a JIS marking-approved factory (JIS marking products: automotive gasoline, kerosene, diesel, and heavy oil), and in June 2007, it was certified under the "New JIS Marking System."

Additionally, we acquired ISO9002 certification in 1996 and transitioned to ISO9001:2015 in 2018. Through JIS and ISO certification, we strive to "supply quality products economically and stably.''

Manufacturing and shipping of environmentally friendly products

Idemitsu, including this Refinery, has been commercializing low-benzene gasoline "Idemitsu Super ZEARTH" and "Idemitsu ZEARTH," which have benzene content reduced to less than 1%, since 1993, ahead of the legal restrictions that came into effect in 2000.We have also been producing low-sulfur diesel, with sulfur content reduced to 50 ppm, since 2003, ahead of the 2005 regulations.

On the other hand, Europe (EU) has decided to reduce the sulfur content of gasoline and diesel oil to 10 ppm or less (referred to as sulfur-free) since 2009.

In Japan, sulfur-free diesel was legally mandated in 2007, and gasoline in 2008. Anticipating these regulatory trends, oil refineries and wholesalers that are members of the Petroleum Association of Japan began shipping sulfur-free gasoline and diesel from their Refinery in January 2005, ahead of the rest of the world.

Our Refinery also began shipping sulfur-free gasoline and diesel in January 2005 thanks to the newly constructed gasoline desulfurization facility.

*Unit: 10ppm is 0.001%.

*Sulfur-free means that the sulfur content (sulfur) contained in automobile fuel (gasoline, diesel oil) is 10 ppm or less.

Measures to reduce the environmental impact of gasoline

| | Idemitsu's response | National environmental regulations |

|---|---|---|

| 1975 | Unleaded regular gasoline (Idemitsu Red Apollo Gasoline) | |

| 1983 |

Unleaded premium gasoline (Launch of Idemitsu unleaded gold Apollo gasoline) |

|

| 1993 |

Start of supply of low benzene gasoline (1% or less) ・Premium gasoline (Idemitsu Super ZEARTH) |

|

| 1996 | Benzene content is regulated to 5% or less, sulfur content is regulated to 100ppm or less | |

| 2000 | Benzene content regulated to 1% or less | |

| 2005 | Early start of supply of sulfur-free (sulfur content 10ppm or less) products | Sulfur content regulated to 50ppm or less |

| 2008 | Sulfur content regulated to 10ppm or less |

* Units (%, ppm) in the table are volume % and mass ppm

Transition and response to low-sulfur differentiation of diesel oil

| | Idemitsu's response | National environmental regulations |

|---|---|---|

| 1976 | Supplying products with sulfur content of 0.5% or less | Sulfur content regulated from 1.2% to 0.5% or less |

| 1992 | Supplying products with sulfur content of 0.2% or less | Sulfur content regulated to 0.2% or less |

| 1997 | Supplying products with sulfur content of 0.05% or less | Sulfur content regulated to 0.05% or less |

| 2003 | Early supply start of products with sulfur content of 0.005% (50ppm) or less (April) | |

| 2005 | Early start of supply of sulfur-free (sulfur content 10ppm or less) products | Sulfur content regulated to 0.005% (50ppm) or less |

| 2007 | Sulfur content regulated to 10ppm or less |

* Units (%, ppm) in the table are volume % and mass ppm

Gasoline desulfurization equipment

The gasoline desulfurization equipment is a device that significantly reduces the sulfur content contained in cracked gasoline refined by heavy oil cracking equipment, and has been shipping sulfur-free gasoline since January 2005 using the produced desulfurized cracked gasoline. doing.

Light oil deep hydrodesulfurization equipment

The diesel oil deep hydrodesulfurization equipment is a device for reducing the sulfur content contained in diesel oil, and since January 2005 we have been producing sulfur-free diesel oil with even lower sulfur content.

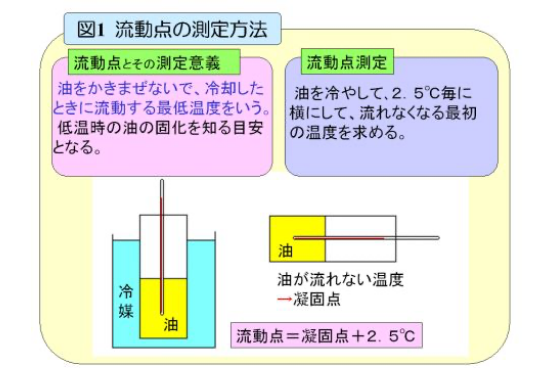

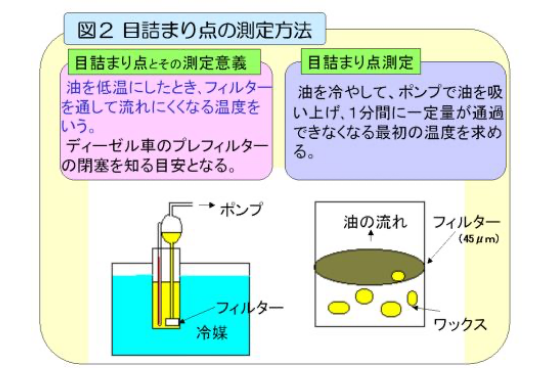

In addition, this equipment has a desulfurization function and a dewaxing function (a function that removes the wax content in light oil), which improves the fluidity (pour point, clogging point) of light oil, and prevents light oil from solidifying at low temperatures in winter. Prevents

Manufacture and shipment of products adapted to the region and season

Our Refinery manufactures and ships a wide range of petroleum products for both consumer and industrial use, including liquefied petroleum gas (propane, butane), gasoline, naphtha, jet Petroleum, kerosene, diesel, heavy oil, and sulfur. We have introduced cutting-edge equipment to increase the production ratio of kerosene and heavy oil A, which are in high demand in northern Japan.

Furthermore, in the winter in cold regions such as Hokkaido and the Tohoku region, it is necessary to ensure that diesel fuel has fluidity at low temperatures (pour point, clogging point: measurement methods are shown in Figures 1 and 2). At our Refinery, we use a diesel deep hydrodesulfurization unit to remove the wax from the diesel fuel, thereby producing and shipping diesel fuel for cold regions with improved fluidity at low temperatures.

Light oil is classified into five types according to JIS standards: Special No. 1, No. 1, No. 2, No. 3, and Special No. 3.

JIS standard

(Source: JIS K2204:2007)

| Test items | Special No. 1 | No. 1 | No. 2 | No. 3 | Special issue 3 | |

|---|---|---|---|---|---|---|

| pour point | ℃ | 5 or less | -2.5 or less | -7.5 or less | -20 or less | -30 or less |

| Clogging temperature | ℃ | - | -1 or less | -5 or less | -12 or less | -19 or less |

| flash point | ℃ | over 50 | 45 or more | |||

| Distillation properties (90% distillation temperature) | ℃ | 360 or less | 350 or less | 330 or less*1 | ||

| 10% residual carbon content | mass% | 0.1 or less | ||||

| Cetane index *2 | - | over 50 | 45 or more | |||

| Kinematic viscosity (30℃) | mm2 /s | 2.7 or higher | 2.5 or higher | 2 or more | 1.7 or higher | |

| Sulfur content | mass% | 0.0010 or less | ||||

| Density (15℃) | g/cm3 | 0.86 or less | ||||

*1 For No. 3 diesel oil, if the kinematic viscosity (30℃) is 4.7mm2/s or less, the temperature should be 350℃ or less.

*2 The cetane number can also be used as the cetane index.

This is classified based on the difference in "low-temperature fluidity" (clogging point, pour point), which is mainly affected by changes in temperature.

When the temperature drops, wax crystals from diesel oil precipitate, which can clog the fuel filter. Furthermore, when the temperature drops, the entire diesel oil becomes solidified, making it difficult to flow through the fuel pipes.

The temperature at which the filter becomes clogged (actually, the temperature at which the pre-filter becomes clogged) is evaluated by a test called the clogging point, and the temperature at which it hardens is called the pour point.

Our Refinery has established standards that are even more detailed than the JIS standards, and we manufacture and ship diesel fuel that is suited to the season and regional characteristics.

quality policy