General rust preventive oil | Industrial lubricating oil

Choosing the right oil is the key to protecting your precious products.

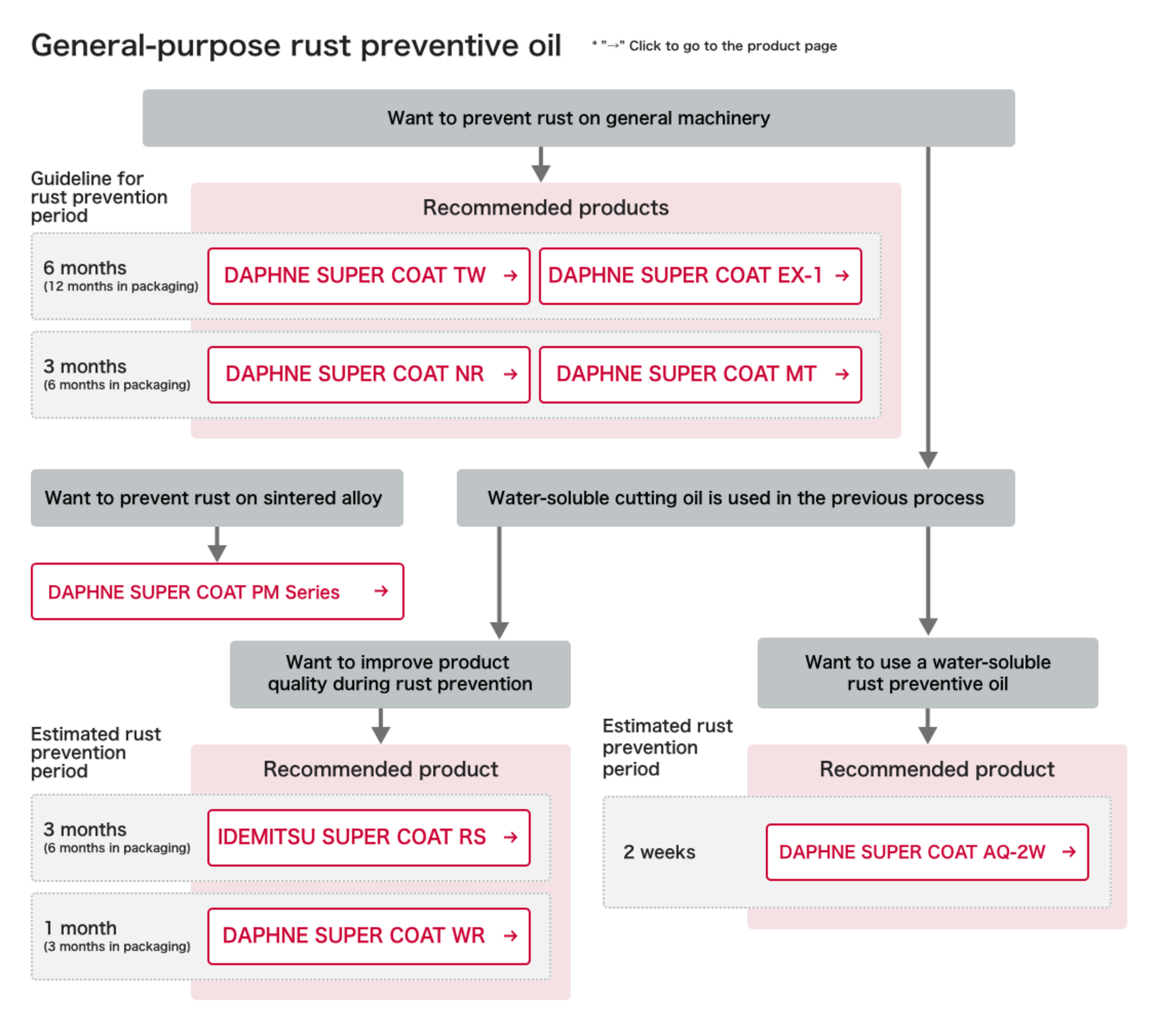

When selecting the appropriate oil, the points to check are the target to prevent rust and confirmation of the pre- and post-processes.

The series of steps, starting with object investigation and process analysis, and ending with checking the location conditions, storage conditions, and confirming the compatibility of the rust preventive oil with post-processing, ensures that the rust preventive oil is used more safely and without excess, waste, or unevenness. This is nothing but preparation before use.

The flow for selecting the appropriate oil for our Daphne Super Coat series is introduced below.

| Product name | Rust prevention guideline | Object | Main features |

JIS2246 Standard equivalent classification |

|---|---|---|---|---|

|

Daphne Super Coat WR |

1 month (indoor, no packaging) 2 months (under packaging) |

Water-based processing parts General mechanical parts |

・Strong water displacement and water separation properties | NP-3-2 |

|

Daphne Super Coat NR |

3 months (indoors, no packaging) 6 months (under packaging) |

General mechanical parts |

・Excellent exposure rust prevention ability ・Excellent rust prevention under wet lubrication conditions ・Water displacement property |

NP-3-2 |

|

Daphne Super Coat TW |

6 months (indoors, no packaging) 1 year (under packaging) |

General mechanical parts |

・Excellent exposure rust prevention ability ・Excellent rust prevention under wet lubrication conditions ・Water displacement property ・Long-term rust prevention ability |

NP-3-2 |

|

Daphne Super Coat AQ-2W |

2 weeks (indoors, no packaging) | General mechanical parts |

・Water-soluble rust preventive oil ・Applicable to non-dangerous goods |

NP-3-2 |

|

Daphne Super Coat PM1 |

6 months (indoor, no packaging) | sintered alloy |

・Excellent exposure rust prevention ability ・Excellent rust prevention under wet lubrication conditions ・Water displacement property |

NP-3-2 |

|

Daphne Super Coat PM3 |

2 weeks (indoors, no packaging) 1 month (under packaging) |

sintered alloy |

・Excellent sizing performance ・Excellent steam processing properties |

NP-3-2 |

|

Daphne Supercoat PM4 |

3 months (indoors, no packaging) 6 months (under packaging) |

sintered alloy |

・Excellent exposure rust prevention ability ・Excellent steam processing properties ・Suppressing discoloration during draining and mixing |

NP-3-2 |

|

Daphne Oil Coat RL-55 |

3 months (indoors, no packaging) 6 months (under packaging) |

thin sheet metal press parts |

・Excellent degreasing properties using alkaline solvents ・Stain resistance ・Water displacement property |

NP-3-2 |