What is lubricants?

What is lubricants?

Lubricating oil is oil used to reduce the friction that occurs when objects move. Reducing friction through the action of lubricating oil not only reduces excess energy consumption, but also extends the life of machines and tools. They are also used in a variety of places for purposes such as wear prevention, cooling, cleaning, and rust prevention, making them indispensable to our society.

familiar lubricant

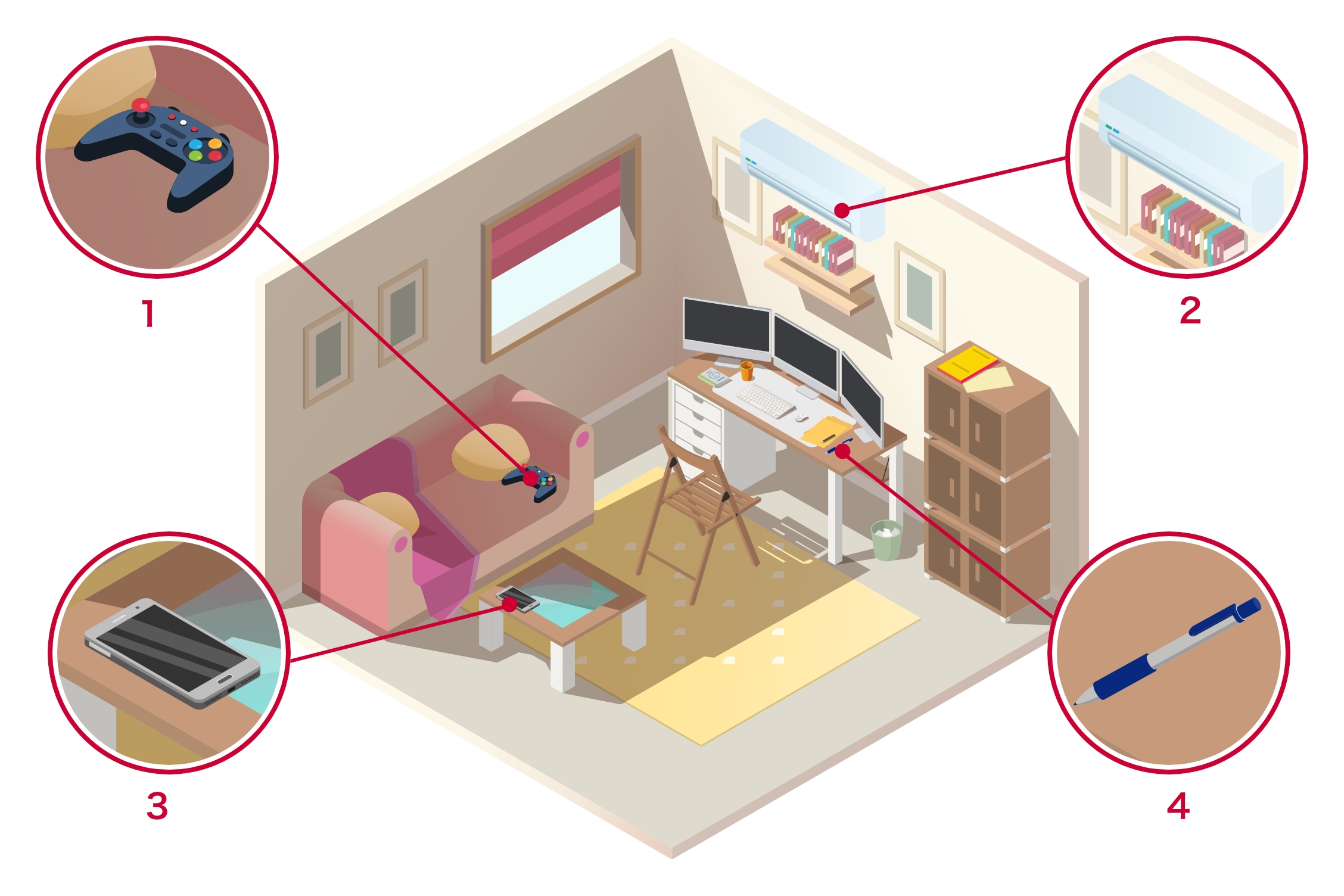

Lubricants are used everywhere around us, such as in the gears of machines, car engines and brakes, the fluid stoppers of ballpoint pens, the bearings of small motors in smartphones and game consoles, and the refrigerant of air conditioners. I am.

-

Game consoles: Lubricating oil is used to ensure smooth operation of the small motor bearings and fans inside.

-

Air conditioner: Supports the operation of the compressor that pumps refrigerant gas.

-

Smartphones: Lubricating oil is used to ensure smooth operation of the small motor bearings and fans inside.

-

Pole pen: The pen is sealed with lubricant to prevent the ink from drying out.

Lubricant is the unsung hero

A variety of contact conditions (machine, material, temperature, load, sliding speed, etc.) exist where lubricants are required. Lubricating oils are designed to accommodate these conditions and create optimal friction conditions.

In addition, as technology advances, the requirements for lubricants have become more diverse. For example, there is a growing demand for lubricants with "high frictional force" to transmit large amounts of power, and lubricants whose "frictional force changes depending on speed'' to improve the ride comfort of automobiles.

In addition to reducing friction, lubricating oil also plays a major role in preventing machine wear. In addition, they may play roles such as cooling machines, transmitting pressure, preventing rust, and insulating electricity.

Lubricating oil is said to be an unsung hero, and it can be said that it is indispensable to our society.

Lubricant and friction

If there was no frictional force

If you give a small shock to the sand pile inside the hourglass, the angle of the pile will be approximately 30 degrees. The slope of the summit of Mt. Fuji is also about 30 degrees. This is not just a coincidence, but is due to the balance between gravity and the coefficient of friction between the sand. In civil engineering, this angle is called the "angle of repose."

If there were no frictional force in this world, Mt. Fuji would not exist and people would not be able to admire its majestic figure. In fact, there is no friction between the ground and the soles of our feet, so we wouldn't even be able to walk.

Since recorded history, humans have had a deep relationship with this frictional force. It is said that in ancient Egypt, when carrying megaliths, they used "rollers" and lubricating oil (presumably olive oil).

In the 16th century, Leonardo da Vinci said, "When any object tries to slide, it produces a resistance called friction, whose magnitude is one-fourth of its weight." This was the first time in history that the magnitude of friction was described, and in today's terms, it means that the coefficient of friction is 0.25. In the 18th century, French authors such as Amonton and Coulomb pioneered the theory, and today it has become an academic field called "TRIBOLOGY."

Prevent direct surface-to-surface contact

Friction is an essential part of human life, but it is not very welcome for machines. This is because high friction causes energy loss and machine wear. Therefore, by putting lubricating oil between the surfaces that rub together, you can prevent direct contact between the surfaces and reduce friction.

In this way, the forms of lubrication when using lubricating oil can be roughly divided into "fluid lubrication" and "boundary lubrication."

fluid lubrication

Fluid lubrication means that an oil film is formed on the friction part, and the two surfaces are lubricated from a distance without direct contact.

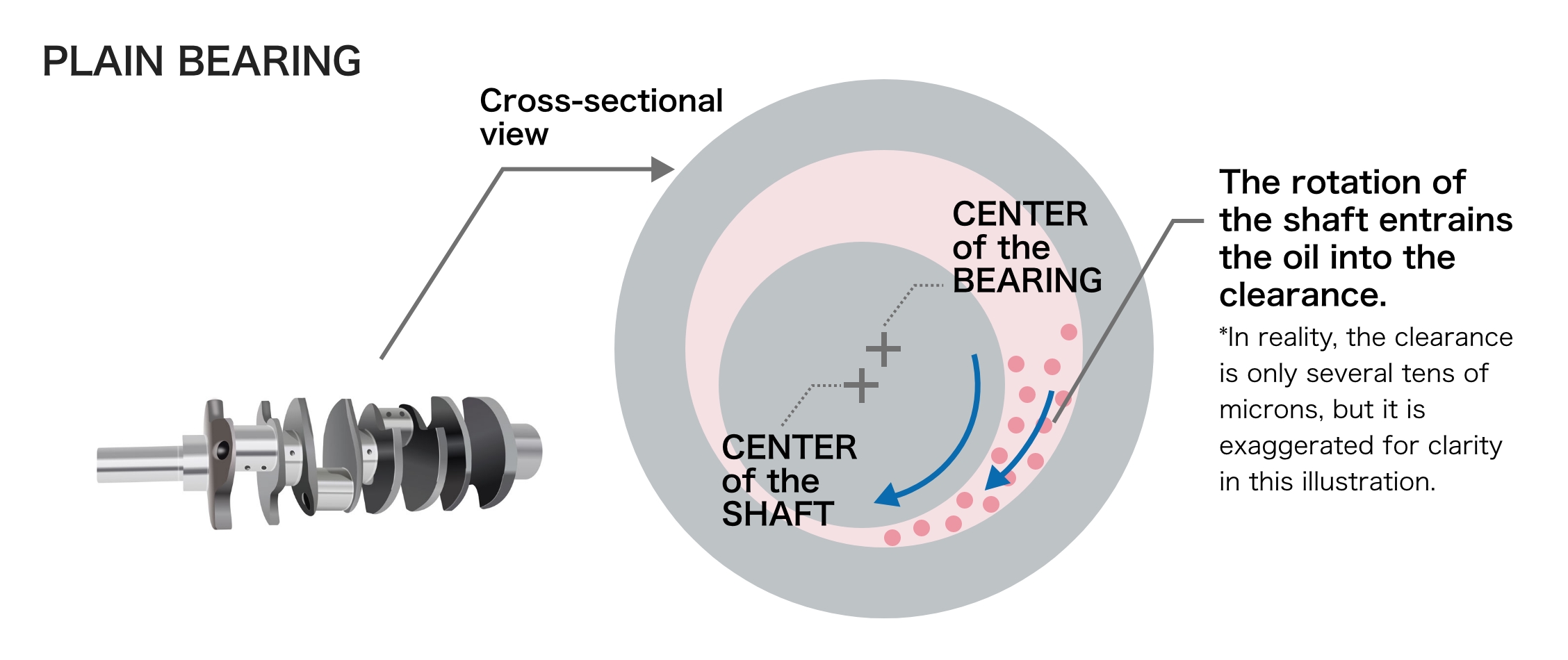

The drag force, or viscosity, of lubricating oil allows objects to float. This form of lubrication is effectively used industrially in "slide bearings." A plain bearing is a type of bearing that supports a rotating shaft and is used in automobile crankshafts, etc.

As the shaft rotates, lubricating oil is dragged into the narrow gap, creating pressure. This pressure lifts the shaft and reduces frictional force. This phenomenon is called the "wedge effect" because the area where the lubricating oil enters is shaped like a wedge.

Boundary lubrication (lubrication in a molecular film)

In situations where a rich oil film cannot be formed, such as in fluid lubrication, a film on the order of molecules lubricates the two surfaces. This is the world of boundary lubrication, where the chemical properties of the surface matter. A small molecular film adsorbed on the surface or a surface modification layer created by additives reduces the frictional force.

Generally, lubricating oils are made by mixing additives with base oil made by refining crude oil. Even an adsorbed film of additives with just a dozen or so molecules can significantly lower the coefficient of friction. Sometimes more than 20 types of additives are combined.

If you're not careful, you'll get burnt out.

I'm not sure if the ancients said, "To be careless is to be let down," but the lubricating oil that gets between two surfaces will also be cut off under extremely harsh friction conditions.

This exposes the solid surface underlying the membrane, causing friction between the solids. Then, strong adhesion occurs between the two surfaces, and eventually a phenomenon of burning occurs. In the case of metal, it sticks together as if it were welded, which can be fatal for a machine.

The harsh conditions here include high loads, high temperatures, etc. In the past, the cause of car engines burning out due to high-speed, long-term operation was the rupture of the lubricating film due to high temperatures.

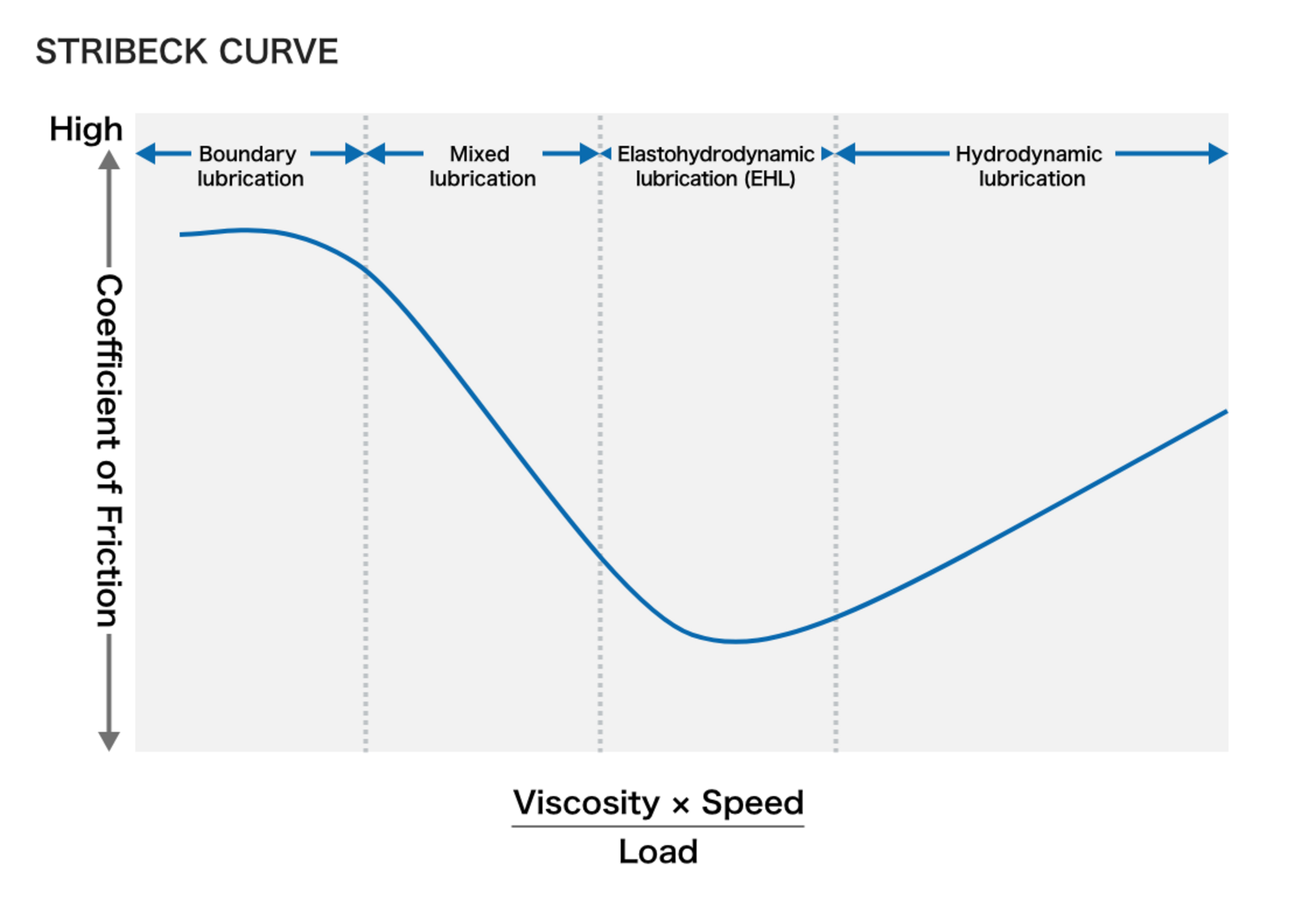

"Stribeck curve"

To help understand these forms of lubrication, there are curves as shown in the figure. This is the so-called "Stribeck curve," and it often appears when discussing friction.

This curve has the coefficient of friction on the vertical axis and [viscosity x speed/load] on the horizontal axis, and when the operating conditions of the machine are changed, the curve shown in the figure is generally drawn.