Thermosetting resin (development product)

It is a one-component thermosetting resin that can be molded using a liquid injection molding machine.

Molding

Characteristics of the developed product

-

A new type of soft thermosetting material that is a one-component type with low viscosity and fast curing speed.

-

Due to its molecular structure, there is no risk of hydrolysis and it has high water vapor barrier properties.

-

It is possible to change the material properties, and it is possible to adjust the material to meet the required properties.

Representative characteristic values of the developed product

| Characteristics (unit) | Evaluation method | Development product 1 | Developed product 2 (flame retardant type) | |

|---|---|---|---|---|

| liquid component | liquid type | 1 liquid | 1 liquid | |

| Curing conditions | ー |

1 minute -85~℃ Post-curing - no |

1 minute -85~℃ Post-curing - no |

|

| Viscosity (25℃, Pa・s) | JIS K 7117-2(ISO 3219) | 2 | 2 | |

| bending properties | Elastic modulus (MPa) | JIS K 7171(ISO 178) | 5 | 30 |

| Maximum stress (MPa) | 0.5 | 2.5 | ||

| Shore hardness(23℃) A/D | JIS K 7197(ISO 11359-2) | 70/10 | 90/40 | |

| Water vapor permeability (g/m² ・day) | 25℃, 90%RH | JIS K 7129 B method | 50 | 30 |

| 40℃, 90%RH | 130 | 90 | ||

| Flame retardance | UL94 | ー | V-0 equivalent (3mm) | |

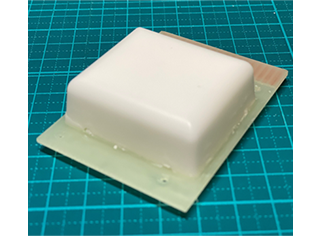

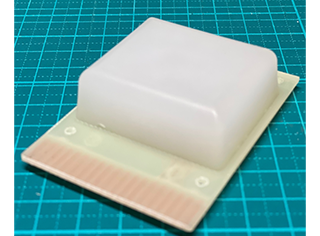

| Molding | ||

|---|---|---|

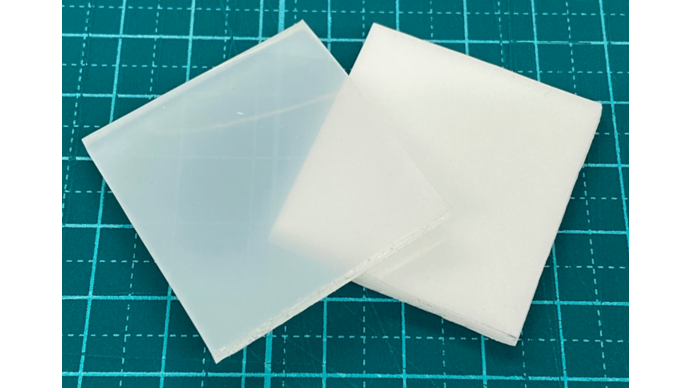

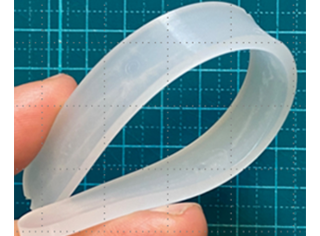

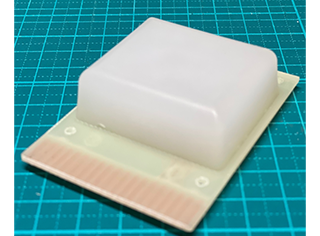

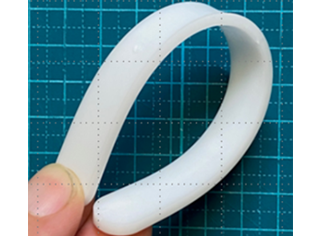

| Bar type (bent) | cubic type | |

| Development product 1 |

|

|

|

Development product 2 (Flame retardant type) |

|

|

We improve viscosity and material properties to meet your needs.

Molding method example

| Molding machine | A liquid injection molding machine or an injection molding machine with an injection unit compatible with liquid materials is required. |

|---|---|

| Handling |

Since it is a solvent-free, one-component type, it is easy to handle at the molding site. Since curing failure occurs in the presence of air, it is necessary to reduce the pressure inside the mold during molding. |

|

low filling pressure Low material loss |

Since it is a low viscosity liquid, the filling pressure during molding can be lowered. Therefore, when performing insert molding, the load on the insert can be greatly reduced. Since the runner and sprue can be made thinner, it is expected to reduce material loss. |

| Product shape | Because it is a low viscosity material, it can be injected into various shapes and places with little clearance. |

| Typical molding conditions (example of study using our research equipment) | ||

|---|---|---|

|

1) Molding machine type | Plunger injection molding machine |

| 2) Cylinder and nozzle temperature | 15℃ | |

| 3) Mold temperature | 125℃ | |

| 4) Injection time | 1 second | |

| 5) Holding pressure | 10MPa | |

| 6)Curing time | 120 seconds * | |

*60 seconds if the thickness is around 3mm

Expected usage examples

Sealing materials for vibration absorption, moisture proofing, and waterproofing from low to high temperatures for automobiles, power storage devices, and displays.

Part to be sealed

-

Automotive: Bulk sealing material for electronic parts with coil parts such as inductors, small sensors, ECUs, and optical (communication) parts

-

Energy storage field: Encapsulating materials for electronic components, packing and sealing materials for solid batteries, fuel cells, tanks, etc.

-

The data and descriptions in this document are for reference when designing products using this developed product.

Although the information contained herein is based on reliable testing and information, the data and statements should not be considered absolute.

When applying to individual products, be sure to separately confirm the validity of the design. -

The uses described in this document do not guarantee the results of applying this product to those uses.

-

When making an inquiry, please select "Petrochemical" as the inquiry category.