Hokkaido Refinery | Safety Initiatives

At Hokkaido Refinery, we take seriously the seriousness of the tank fire that occurred following the Tokachi-oki earthquake in 2003, as well as past equipment fires. We have listened carefully to the opinions of external experts and striven to strengthen safety and prevent the recurrence of such accidents.

All employees Hokkaido Refinery work together to implement activities to prevent serious accidents, based on the principle of "safety first."

Additionally, in preparation for the unlikely event of a fire, oil leak, etc., we will strengthen our disaster prevention equipment and systems, take thorough measures to prevent recurrence, and make every effort to strengthen security.

Main safety enhancement measures

Thorough early detection and early reporting of abnormal phenomena

Two wide-area surveillance cameras are installed at the top of the collective chimney to monitor the entire Refinery.

Further strengthen education and training on how to identify and report abnormal phenomena

Strengthening cooperation with related organizations during disasters

Involve relevant organizations such as self-defense disaster prevention organizations, public firefighting organizations, joint disaster prevention organizations, and maritime disaster prevention organizations.

Planned joint disaster prevention drills and conducted practical training to strengthen collaboration

Developed disaster prevention tactics and conducted education and training assuming a full-scale tank fire

Created disaster prevention measures using large-capacity foam cannon (already introduced)

Organize a "large-capacity foam gun corps" to strengthen self-defense and disaster prevention systems

Technology and equipment handling education and training related to large-capacity foam cannons

Improvement of security system and organization

Process safety experts are assigned to the safety and environment offices of each Refineries/Complexes

Technical staff assigned to the Hokkaido Refinery Engineering Department

Acquired high pressure gas certification (completion/safety) inspection implementer certification.

Our office was certified as a specific certified business (commonly known as a super certified Complex) by the Minister of Economy, Trade and Industry under the new certified business system established by the Ministry of Economy, Trade and Industry on June 29, 2021. This is the first time that Complex in Hokkaido has received this certification.

We will continue to strive to improve our independent safety measures and work to ensure safe operations and a stable supply of energy.

Obtained certification for 2-year, 4-year, and 8-year open inspection cycles for boilers and first-class pressure vessels.

As of April 20, 2017, our office has been certified for 2-year, 4-year, and 8-year open inspection cycles for boilers and Class 1 pressure vessels. We will continue to strive for safe operation of boilers and first-class pressure vessels.

Updated on May 10, 2020.

Strengthening security capabilities through third parties

In January 2020, Hokkaido Refinery underwent a "security capability (safety foundation and safety culture) evaluation" by the Safety Capability Improvement Center, a specified non-profit organization. As a result, we received high evaluations in many indicators, including our "Process Safety Design System'' and "Company-wide Human Resource Development Education System,'' which we have been working on for a long time. On the other hand, in the evaluation of "safety infrastructure and safety culture," opportunities for improvement were found in several indicators, and we received advice in areas such as (1) implementation standards for process risk assessment, (2) division of roles in maintenance management, etc. We are working on improvements with the aim of further increasing the level of safety.

Overview of fire protection equipment

fire engine

| large chemical fire engine | Two | 5,000L/min |

|---|---|---|

| Large chemical aerial water cannon vehicle | One | 3,800L/min |

| Foam concentrate transport vehicle | One | 4,000L |

| Disaster prevention command vehicle | One | Equipped with communication equipment, etc. |

| Equipped car | One | Equipped with disaster prevention equipment, etc. |

emergency training

Chemistry car 3 piece set

Left: Large chemical aerial water cannon truck Middle: Large chemical fire engine Right: Foam concentrate transport vehicle

The large chemical high-altitude water cannon truck, large chemical fire engine, and foam concentrate carrier used for firefighting are called the "3-piece chemical vehicle set.'' The large chemical high-altitude water cannon vehicle uses a fully automatic control system that allows the outriggers and boom to be extended, stowed, and mixed with fire extinguishing agent at the touch of a switch, and the boom can be extended up to 27 meters in 1 minute and 30 seconds. A large chemical fire engine mixes extinguishing agents under full automatic control and extinguishes fires by controlling water cannons remotely. The undiluted foam carrier replenishes the undiluted fire extinguishing foam used by large chemical fire trucks.

Disaster prevention command vehicle

This will serve as the on-site command center during disaster prevention activities.

It is equipped with equipment necessary for the command post, such as radios, emergency telephones, and whiteboards for recording.

Equipped car

It is equipped with materials and equipment necessary for disaster prevention activities, such as simple fire protection clothing, fire protection shoes, and Lifezem.

Wide area surveillance camera

Installed in 2 locations at the top of the chimney

The entire Refinery is monitored by a wide-area surveillance camera installed at the top of the chimney.

oil fence

Oil fences installed at three locations facing the Tomakomai Port bay

If oil spills onto the sea, this oil fence will be deployed to prevent the spilled oil from spreading.

Disaster control room

Disaster prevention equipment such as water fire extinguishing equipment and foam fire extinguishing equipment is controlled from the disaster prevention control room.

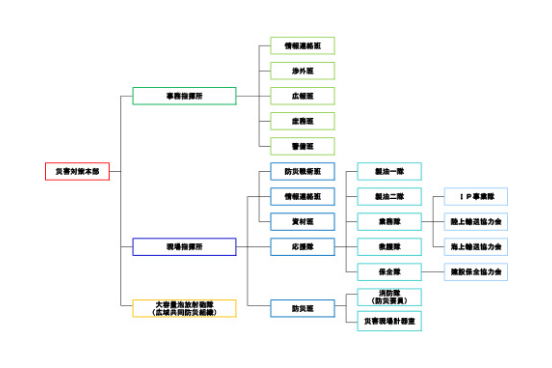

Self-defense disaster prevention system in case of emergency

Tomakomai Petroleum Complex Special Disaster Prevention Area Council

It is composed of the Tomakomai District Joint Disaster Prevention Organization (10 Complex) and the Oil Stockpiling Base Joint Disaster Prevention Organization (2 Complex), and provides mutual support in the event of a disaster.

Fire truck deployment of the Tomakomai District Joint Disaster Prevention Organization

We have large aerial water cannon trucks, large chemical fire trucks, large chemical aerial water cannon trucks, and foam concentrate transport vehicles.

10 Complex in the Tomakomai area joint disaster prevention organization

-

Iwakura Chemical Industry Co., Ltd.

-

Tomakomai Oil Terminal oil terminal, Ltd.

-

New Oxygen Chemical Co., Ltd.

-

Japan Resources Exploration Co., Ltd. Hokkaido Complex Yufutsu Plant

-

Tomakomai Pier Co., Ltd. Oil Terminal Division

-

Toyota Motor Hokkaido Co., Ltd.

-

Hokuren Tomakomai Oil Storage Facility

-

Hokkaido Soda Co., Ltd. Production Technology Headquarters Tomakomai Complex

-

Hokkaido Power Engineering Co., Ltd. Tomakomai Complex

-

Our company, Hokkaido Refinery

Fire engine deployment of oil storage base joint disaster prevention organization

We have a large chemical fire engine, a large chemical aerial water cannon truck, and a foam concentrate transport vehicle.

Oil storage base joint disaster prevention organization 2 Complex

-

Tomakomai Complex Tomato Oil Storage Co., Ltd.

-

Hokkaido Joint Oil Stockpiling Co., Ltd. Hokkaido Complex

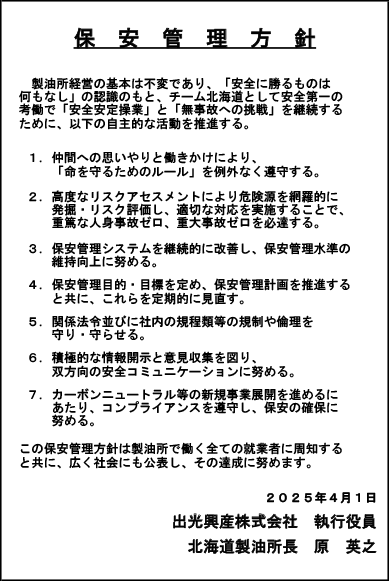

Security management policy