Hokkaido Refinery | Environmental Initiatives

Based on our basic policy of "creating Refinery that is loved by the local people," this Refinery began operations in 1973 with the aim of becoming a "park factory in the northern land," and has since worked hard to ensure a stable supply of petroleum to northern Japan.

With the aim of harmonizing with the natural environment of Hokkaido, we have not only reduced the environmental impact on air and water quality, but also used low-benzene gasoline and sulfur-free (sulfur content of 10 ppm or less) gasoline. We have achieved results through initiatives such as creating products that do not place a burden on the environment and reducing waste, such as installing volatile hydrocarbon recovery equipment in lorry shipping facilities. We will continue our activities to make further improvements.

The employees working at this Refinery will not only further raise their awareness of safety and the environment, but also recognize that each and every one of them is also a global citizen, and will continue to make tireless efforts to pass on Hokkaido's rich natural environment to the next generation.

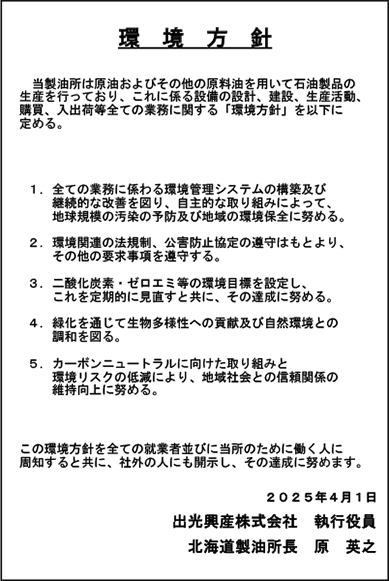

Environmental policy

Applicable site: 25-1, 25-4, 26-1, 26-2, 9-1, 10-1, 11-6, 11-12, 28-1, 39, 40, 41- Masago-cho, Tomakomai City, Hokkaido 1, 42-2

This does not apply to technical dispatched employees stationed on the Idemitsu Kosan Co.,Ltd. Hokkaido Refinery premises (applies to employees and partners belonging to Hokkaido Refinery).

Representative products: LPG, naphtha, gasoline, kerosene, jet fuel, light oil, heavy oil, sulfur, electricity, etc.

Imported, brought in, auxiliary materials, etc.: crude oil, kerosene, propane, butane, additives and chemicals (anticorrosion agents, compounding agents, etc.) desulfurization/reforming catalysts

Promotion of energy conservation

In order to use limited energy resources efficiently, Refinery has implemented meticulous energy management by introducing highly efficient equipment and setting operational management values. We will continue to promote energy conservation in the future, aiming to reduce our energy consumption intensity by an average of 1% or more per year in the medium to long term.

Initiatives to reduce waste

Our Refinery established zero emissions activities in fiscal 2002, with the goal of achieving zero emissions in fiscal 2008. As a result, we achieved this goal two years ahead of schedule, in fiscal 2006. Currently, in order to further promote zero emissions, we have set a target of keeping the final (landfill) disposal amount of 0.1% or less of the amount generated, since fiscal 2015, and have achieved this every year.

*Definition of achieving zero emissions: The amount of final (landfill) disposal is less than 1% of the amount generated.

In addition, the Refinery is examining ways to improve waste management based on the 3Rs (Reduce, Reuse, Recycle), and is working with the Tomakomai Zero Emission Network, which is made up of 11 neighboring companies, to gather information and advance its activities.

Waste recycling station in the office

Collection status of waste fluorescent tubes and waste batteries

Environmental measures

Air pollution prevention measures

Flue gas desulfurization equipment that reduces SOx

Our Refinery generates sulfur oxides (SOx), nitrogen oxides (NOx), and soot and dust from its boilers and heating furnaces. To reduce the burden on the environment, we have installed flue gas desulfurization equipment for SOx and smoke denitrification equipment for NOx. Soot and dust is removed using electrostatic precipitators and filters. Through these reduction measures, we comply with the emission standards set by the Pollution Prevention Agreement, which are stricter than the Air Pollution Control Act.

Water pollution prevention measures

Our Refinery uses industrial water for cooling products and semi-finished products, etc. After use, we measure the hydrogen ion concentration (pH), chemical oxygen demand (COD), suspended solids (SS), and normal hexane extractables content of the water, and comply with the discharge water standards stipulated in the pollution prevention agreement.

Soil pollution prevention measures

The Soil Contamination Countermeasures Act came into force in 2003, making it mandatory to conduct surveys of the soil contamination status when specific facilities that use hazardous substances are closed or when the governor recognizes that there is a risk of health damage.

Based on the Soil Contamination Countermeasures Act, our Refinery is conducting surveys to grasp the actual state of soil contamination and to investigate potential risks.

Initiatives to control chemical substance emissions

Volatile hydrocarbon recovery equipment

Of the chemical substances discharged from our Refinery, those subject to the PRTR Law (Law concerning reporting, etc., of the release of specific chemical substances into the environment and promoting improvements in their management) include benzene, toluene, xylene, etc., which are contained in crude oil and naphtha.

To reduce chemical emissions, we use airtight floating roof tanks to store volatile substances and have installed volatile hydrocarbon recovery equipment on our tanker shipping facilities.

environmental data

Factory green space and biodiversity

Since the Refinery began operations, we have been working on greening activities in the harsh environment that is unique to Tomakomai, including sea breezes and volcanic ash.

In order to protect the trees planted on the premises from the sea breeze, we have installed net fences and created rocky mountains, and are now growing approximately 12,000 trees, including Japanese white birch, Japanese black pine, and other trees.

In addition, more than 100 double cherry blossom trees that are over 40 years old have been planted along the straight road on the south side of the premises, and are open to the public during the cherry blossom viewing season every year and are well received.

Row of double cherry blossom trees

net fence

In August 2010, we received the "Social and Environmental Contribution Green Space Evaluation System'', which is a certification system for evaluating and certifying excellent greenery with a high level of contribution, operated by the Urban Greening Organization. It has been certified as a green space.

Since our operations began in 1973, we have been promoting environmental communication by creating green spaces at our plants, giving due consideration to biodiversity, and consciously working to coexist with wild birds and other plants and animals that live on our premises.

Corporate forest

Since December 1996, corporations and other corporations have taken advantage of the Forestry Agency's "Corporate Forests" system to participate in the maintenance of national forests and carry out social and environmental contribution activities. We manage the forest under the name "Appenai Water Forest". The contribution of this forest to the environment has been evaluated as absorbing 212.9 tons of carbon dioxide over 10 years.

In May 2008, we newly leased 4.5 ha of revenue-sharing afforestation in Tomakomai City.

This area was damaged by fallen trees in Typhoon No. 18 in 2004, and in June 2008, 102 elementary school students from the city were invited to participate in a tree-planting experience, and 6,500 trees of Scots spruce, white birch, and double cherry trees were planted. Did.

This forest has been named the "Idemitsu Green Natural Forest,'' which was chosen by elementary school students who participated in the tree-planting project, and will be maintained over the next 80 years.

According to the Forestry Agency evaluation method, the environmental contribution of the "Idemitsu Appenai Water Source Forest" and the "Idemitsu Green Natural Forest" in 2021 is 32.7 tons of carbon fixed and 3,957 cubic meters of water storage benefits in the basin.

In recognition of these activities, in 2019, our refinery was promoted to the "Superlative Stage" (highest stage) in the SEGES green certification system run by the Organization for Landscape and Urban Green Infrastructure. This is the first time that our Refinery has been certified in Hokkaido.