Initiatives towards low carbonization

CO₂ fixation on asphalt pavement

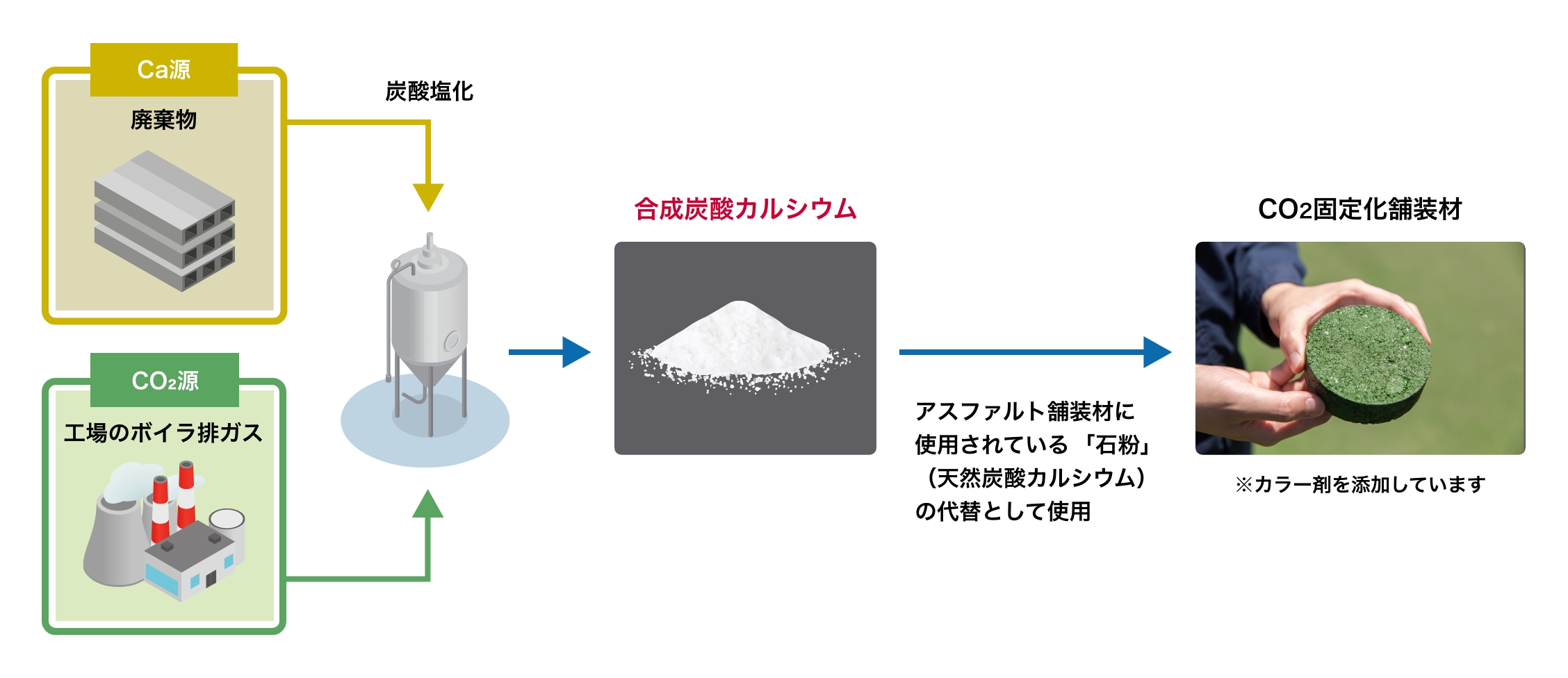

Using calcium contained in concrete waste, CO₂ in exhaust gas emitted from boilers, etc. fixed * We are collaborating with Nippon Concrete Industries Co., Ltd. on a business to manufacture and sell synthetic calcium carbonate. CO₂ from natural calcium carbonate If it were possible to completely switch to fixed synthetic calcium carbonate, approximately 1.2 million tons of CO₂ would be saved annually. It becomes possible to fix.

* Avoid incorporating CO₂, which causes global warming, into substances and releasing it again.

Synthetic calcium carbonate produced by the two companies using CO2 Resources technology

CO2 reduction by lowering product usage temperature

Asphalt is solid at room temperature, but becomes liquid at high temperatures. A mixture of heated stones, sand, and asphalt is soft and can be laid flat and leveled. After it is spread, it hardens as it cools, creating a pavement that cars can drive on.

Granphalt ART, developed by our company, can lower the heating temperature of the composite material compared to conventional products, and reduces CO₂ emissions by reducing fuel consumption required for heating.