recycling used plastics

Current status of used plastics

The importance and social needs of promoting plastic Resources circulation are increasing due to issues such as marine plastic waste and climate change.

In Japan, of the approximately 8.2 million tons of used plastic produced each year, only about 20% is used for recycled products. More than 50% of used plastics are difficult to recycle, so they are incinerated as thermal recycling *, emitting large amounts of CO₂. As one solution to this issue, unprecedented, revolutionary chemical recycling technology is required.

*Thermal recycling: A recycling method that recovers and uses the thermal energy generated when burning plastic and other waste.

About oil chemical recycling

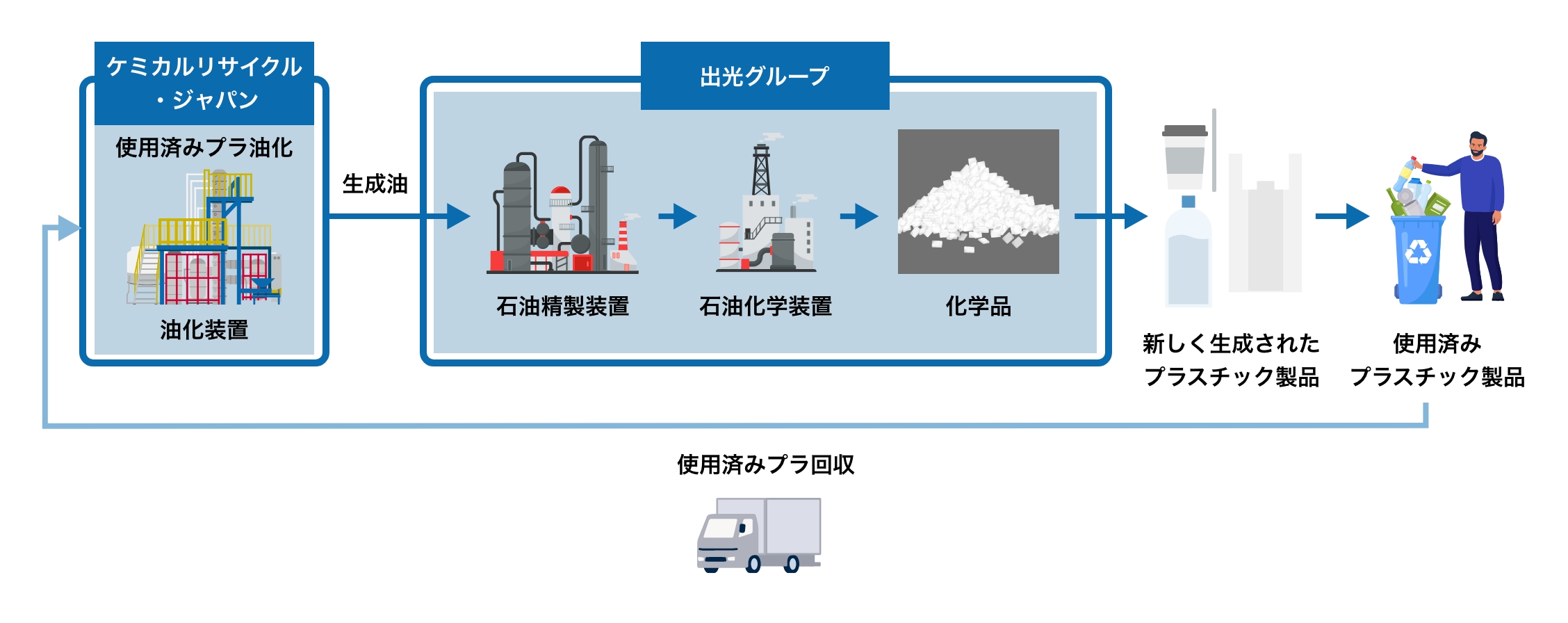

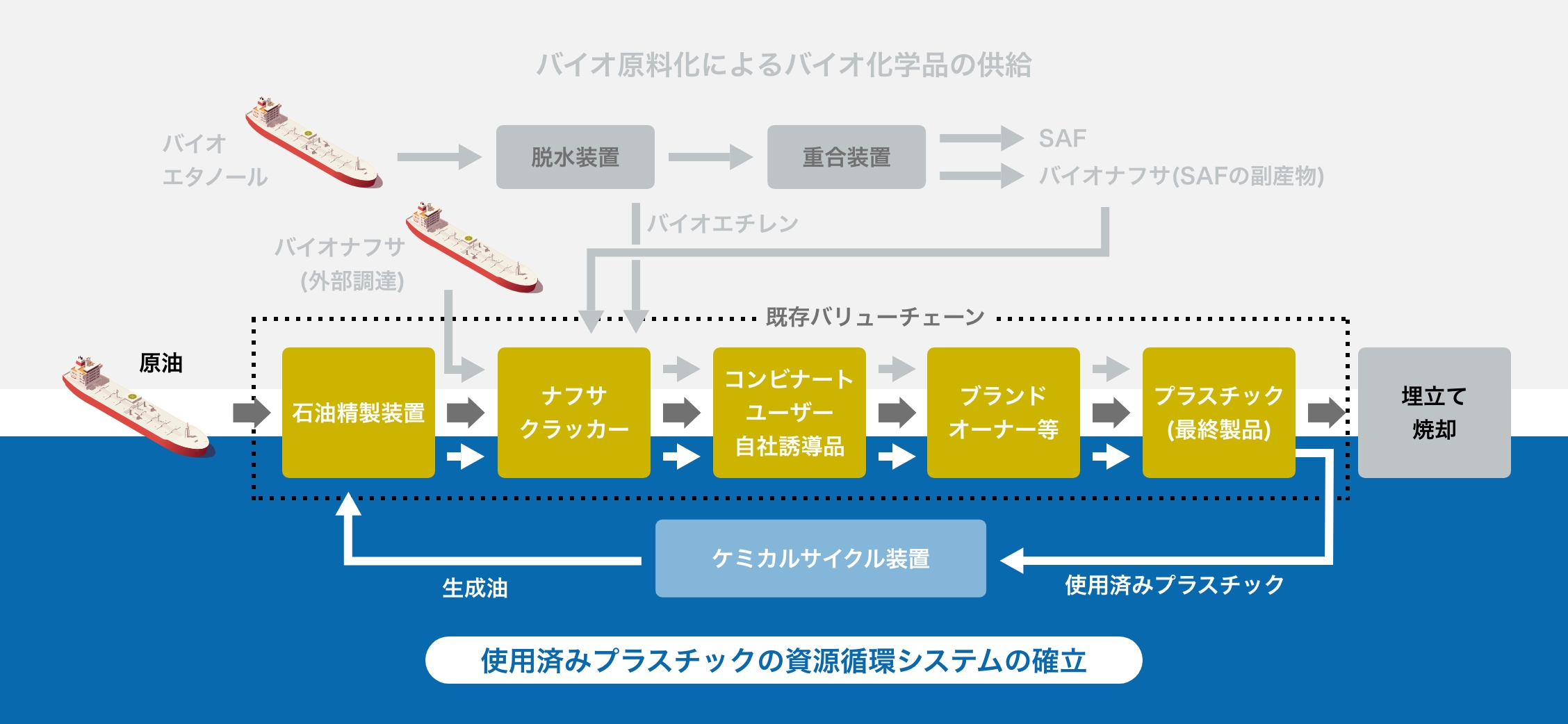

Idemitsu Kosan is working on oil-chemical recycling. Collected used plastics are heated and decomposed using a catalytic cracking method called HiCOP, which turns them into a product oil equivalent to crude oil. This is a Resources initiative in which the product is refined and decomposed in our oil refining and petrochemical facilities, and turned into chemical products again.

We are currently constructing an oil chemical recycling facility (processing capacity: 20,000 tons/year) in an area adjacent to Chiba Complex, aiming to start commercial operation in fiscal year 2025.

In April 2023, we established a joint venture Chemical Recycle Japan, Co., Ltd., with Environmental Energy Co., Ltd., with whom we have been working together to establish technology for oil chemical recycling equipment, to produce recycled oil using used plastics as a raw material.

Additionally, we are considering collaborating with major recyclers to ensure a stable supply of used plastics as raw materials.

Why we engage in recycling

Our company has been working with fossil fuels for many years and has been deeply involved in plastic manufacturing. Because of this, we believe that we should take responsibility for recycling used plastics.

The oleochemical recycling that we are engaged in can effectively utilize existing equipment such as oil refining equipment and petrochemical equipment, so it is one of the businesses that can leverage the unique strengths of our company, which has developed both oil refining and petrochemical businesses. It's one.

Outlook for the oil chemical recycling business

Once the model for this business has been established, we aim to install oil refining equipment at our group's Refineries/Complexes and other locations. We will also consider constructing oil refining equipment outside of our group as a measure to solve the waste problems faced by local governments across the country. We will proceed with larger-scale business expansion targeting used plastics nationwide.