Building a supply chain for biomass plastics

What is biomass plastic?

Much of the plastic around us is made from fossil fuels. As one of the measures to achieve carbon neutrality by 2050, Idemitsu Kosan is working to manufacture and supply "biomass plastics."

Biomass plastics are plastics made from organic Resources such as plants that have absorbed CO2 from the atmosphere. Because they are made from organic Resources, they can emit less CO2 during production than plastics made from petroleum-derived naphtha.

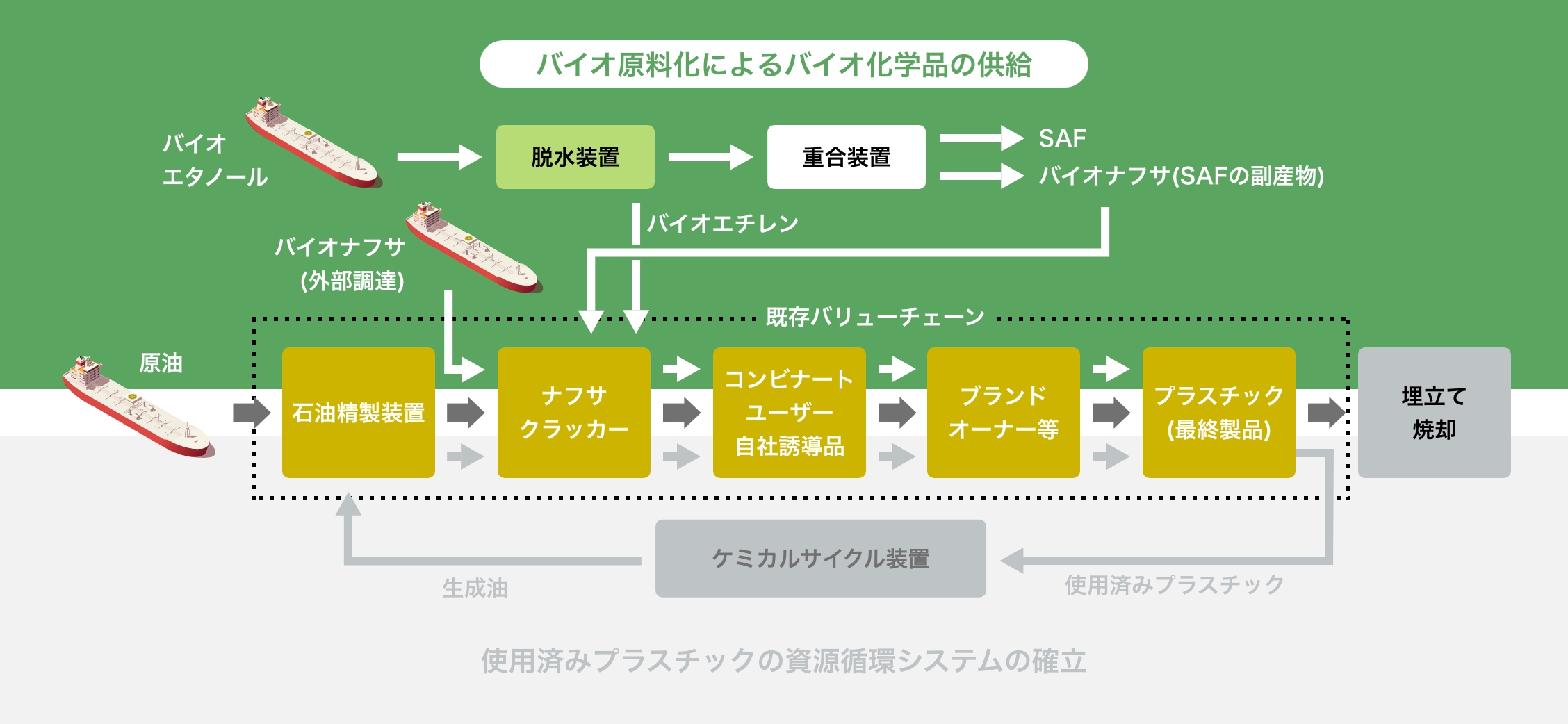

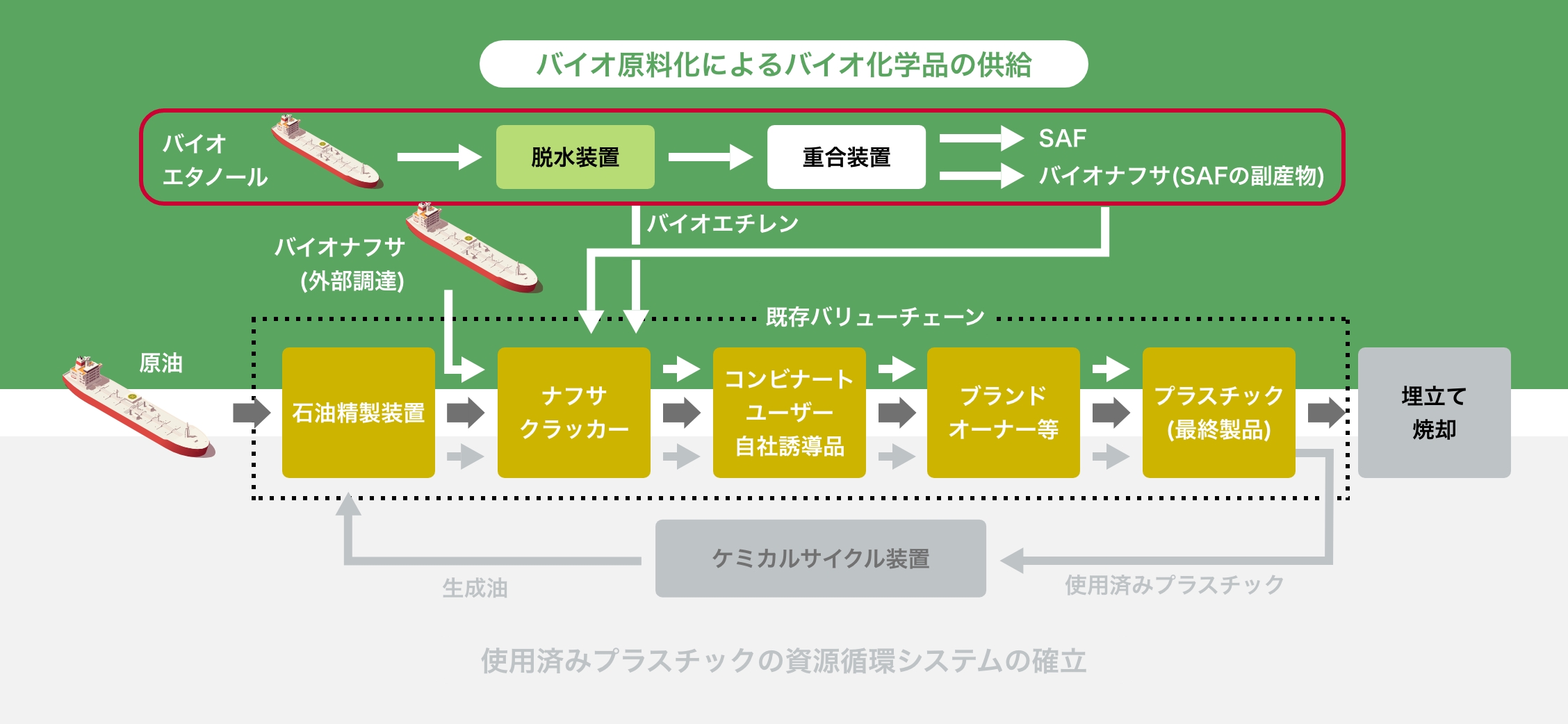

We procure "biomass naphtha" produced from plants and other sources, and are engaged in the manufacture and supply of biomass chemicals such as biomass styrene monomer and biomass paraxylene. We also aim to produce biomass naphtha and biomass ethylene in-house in the future.

What is ISCC PLUS certification?

The ISCC PLUS certification, developed by ISCC *, is an international system that manages and guarantees the supply chain of products that use sustainable raw materials such as biomass. It is an effective mass balance certification system that promotes the use of biomass in the supply chain of the chemical industry, which has a particularly complex production process.

In addition to our Chiba Complex and Tokuyama Complex, Idemitsu SM (Malaysia) and Petrochemicals (Malaysia) have also obtained ISCC PLUS certification.

*ISCC: International Sustainability and Carbon Certification

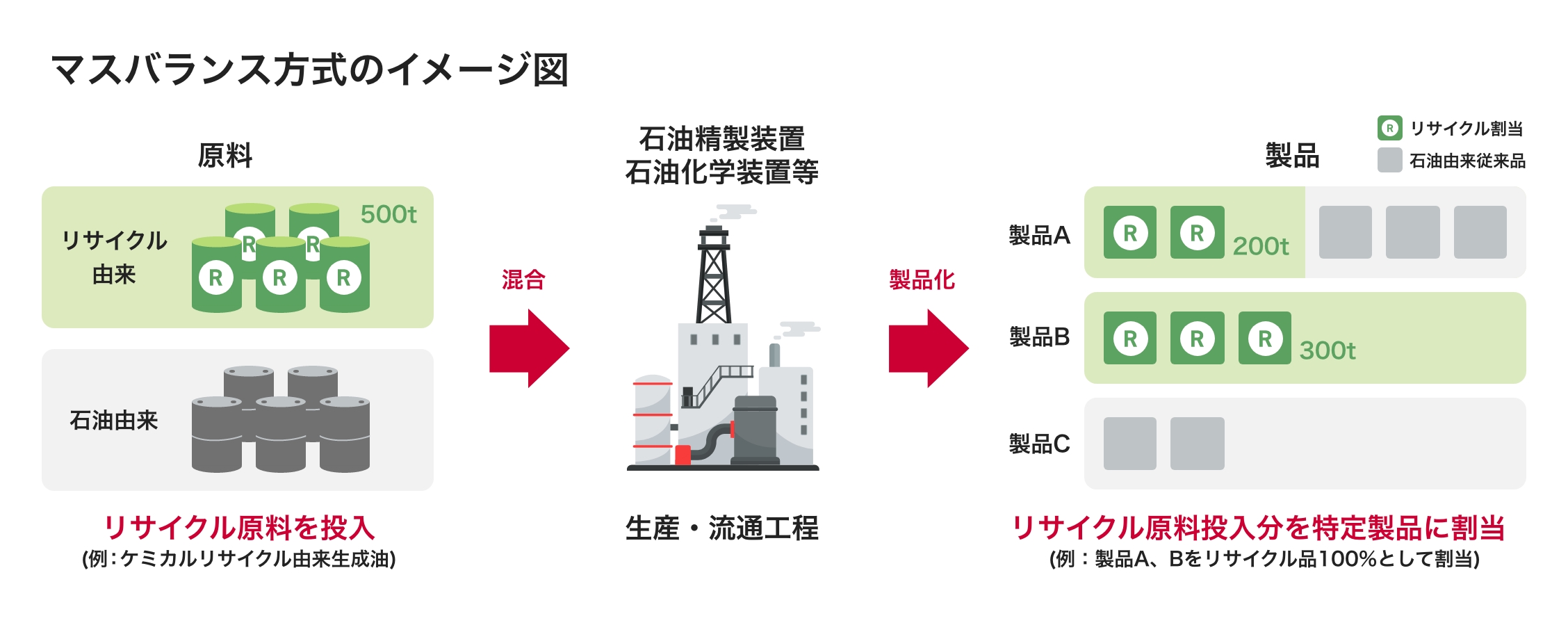

What is mass balance method?

In the processing and distribution process from raw materials to products, when raw materials with certain characteristics (e.g. biomass-derived raw materials) are mixed with raw materials other than those (e.g. petroleum-derived raw materials), raw materials with those characteristics This is a method of assigning characteristics to a part of a product depending on the amount of input. In the chemical industry, where products go through multiple production processes, the mass balance method is considered an effective means of promoting biomass in the supply chain.

Collaboration with SAF (sustainable aviation fuel) production

Our goal is to build a domestic supply system for 500,000 kL of SAF (Sustainable Aviation Fuel) per year in 2030. One of the methods of SAF production we are working on is ATJ (Alcohol To Jet), which uses bioethanol as a raw material. In the process of SAF production using ATJ, biomass naphtha and biomass ethylene are generated as by-products. We aim to manufacture biomass plastics using these as raw materials.

-

As of November 18, 2024